Preparation method of rodlike rutile nano TiO2

A rutile-type, rod-shaped technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., to achieve the effect of simple and easy process steps, simple post-processing process, and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In a 50ml small beaker, while stirring with a magnetic stirrer, add 10.00ml of deionized water, 3.00ml of ethylene glycol, and 6ml of 6mol / L HCl prepared with deionized water, and stir evenly. Then slowly add 10.00 ml of tetrabutyl titanate as a raw material, and stir for 12 minutes to form a light yellow transparent liquid reaction solution. The reaction solution was transferred to a 50ml autoclave and heated to 195oC; the product was taken out after 10 hours of constant temperature. The product was washed three times with absolute ethanol, then washed three times with deionized water, and then placed in a vacuum distillation device, and distilled under reduced pressure at 0.05MPa and 80°C for 20 minutes to obtain a white powdery solid, which is rod-shaped rutile Nano-TiO 2 .

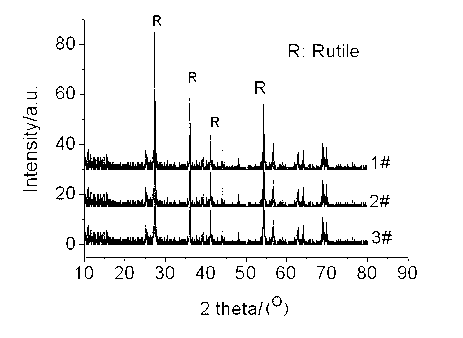

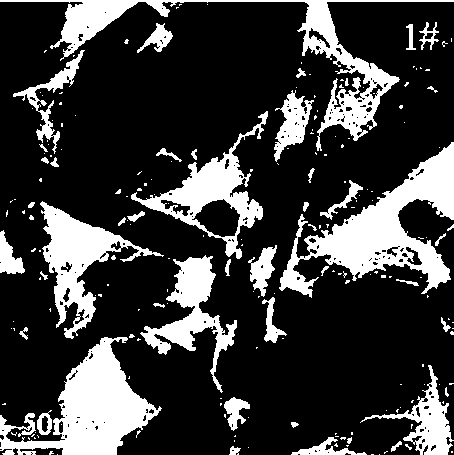

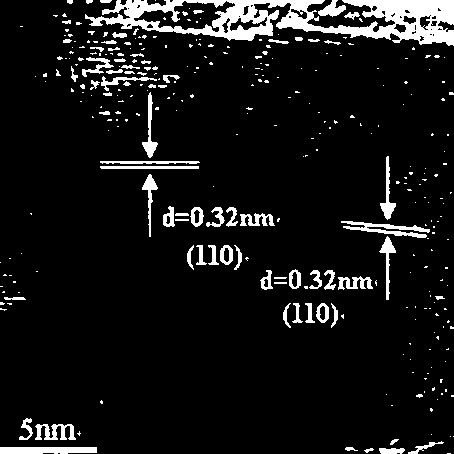

[0035] Characterized by XRD and TEM, rod-shaped rutile nano-TiO 2 The diameter is about 20nm, the length is 50-250nm, and it is rutile phase. After UV-vis analysis, it can be seen that it has...

Embodiment 2

[0037] In a 50ml small beaker, while stirring with a magnetic stirrer, add 10.00ml of deionized water, 5.00ml of ethylene glycol, and 6ml of a 6mol / L sulfuric acid solution prepared with deionized water, and stir evenly. Then slowly add 5.00 ml of tetrabutyl titanate as a raw material, and stir for 8 minutes to form a light yellow transparent liquid reaction solution. The reaction solution was transferred to a 50ml autoclave and heated to 210oC; the product was taken out after 10 hours of constant temperature. The product was washed three times with absolute ethanol, then washed three times with deionized water, and then placed in a vacuum distillation device, and distilled under reduced pressure at 0.01MPa and 50°C for 25 minutes to obtain a white powdery solid, which is rod-shaped rutile Nano-TiO 2 .

[0038] Characterized by XRD and TEM, rod-shaped rutile nano-TiO 2 The diameter is about 20nm, the length is 50-250nm, and it is rutile phase. After UV-vis analysis, it can ...

Embodiment 3

[0040] In a 50ml small beaker, while stirring with a magnetic stirrer, add 10.00ml of deionized water, 1.00ml of ethylene glycol, 6ml of 6mol / L hydrochloric acid solution prepared with deionized water, and the raw material tetrabutyl titanate 8.00ml, stirred for 20min to form a pale yellow transparent liquid reaction solution. The reaction solution was transferred to a 50ml autoclave and heated to 230oC; the product was taken out after 12 hours of constant temperature. The product was washed twice with absolute ethanol, then washed twice with deionized water, and then placed in a vacuum distillation device, and distilled under reduced pressure at 0.02MPa and 60°C for 25 minutes to obtain a white powdery solid in the form of a stick Rutile nano-TiO 2 .

[0041] Characterized by XRD and TEM, rod-shaped rutile nano-TiO 2 The diameter is about 20nm, the length is 50-250nm, and it is rutile phase. After UV-vis analysis, it can be seen that it has no absorption in the visible lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com