Preparation method of antimony sulfide nano rod

A technology of nanorods and antimony sulfide, applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve problems such as uneven size distribution, harsh preparation conditions, and poor product quality, and achieve excellent product quality and low implementation costs The effect of low and high thermal power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

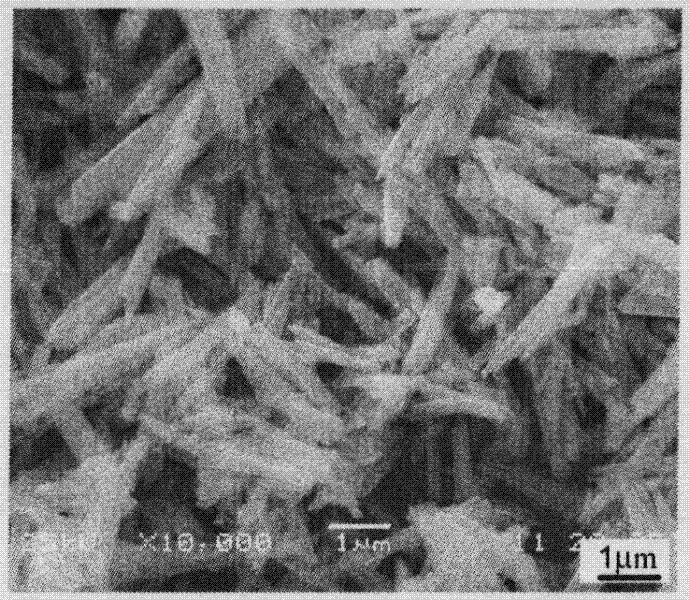

Embodiment 1

[0022] (1) Accurately weigh 1.6g Sb 2 o 3 Added to 50mL ethylene glycol (Sb 2 o 3 The ratio of the amount of substance with ethylene glycol is 1: 160), stir, and then add 1.0g of sulfur powder (the amount of substance of sulfur is Sb 2 o 3 5.6 times of the amount of substance), continue to stir and mix, and mixed solution is transferred in the three-necked flask.

[0023] (2) Slowly add 1.5 g of sodium borohydride (the amount of sodium borohydride substance is 1.26 times that of sulfur powder substance) into the mixed solution while stirring magnetically. Heated with an oil bath and refluxed at 185°C for 15 hours.

[0024] (3) Naturally cool to room temperature after the reaction, centrifuge, and remove the upper liquid to obtain a black precipitate. The obtained precipitates were alternately ultrasonically washed 3 times with deionized water and absolute ethanol respectively, and the obtained samples were dried in a constant temperature drying oven at 60°C for 8 hours t...

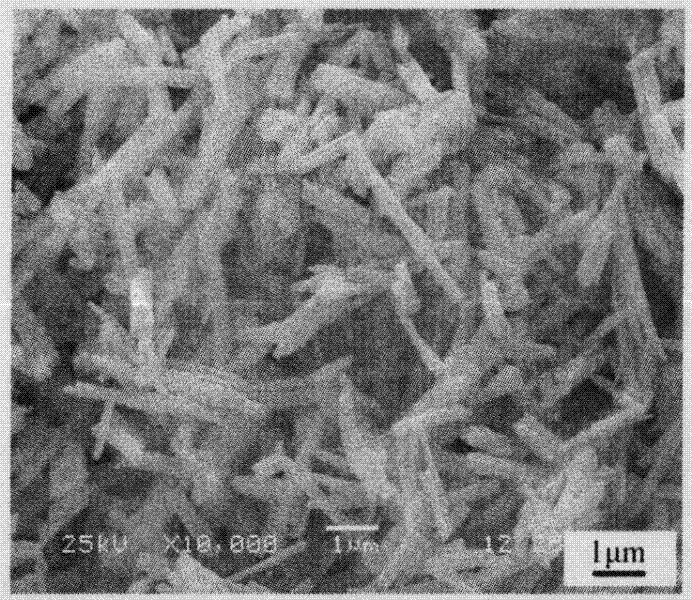

Embodiment 2

[0026] (1) Accurately weigh 1.6g Sb 2 o 3 Added to 60mL 1,2-propanediol (Sb 2 o 3 With 1, the ratio of the amount of substance of 2-propanediol is 1: 150), stir, then add 0.8g sulfur powder (the amount of substance of sulfur is Sb 2 o 3 4.5 times the amount of substance), continue to stir and mix, and the mixed solution is transferred to a three-necked flask.

[0027] (2) Slowly add 1.4 g of sodium borohydride (the amount of sodium borohydride substance is 1.48 times that of sulfur powder substance) into the mixed solution while magnetically stirring. Heated with an oil bath and refluxed at 175°C for 8 hours.

[0028] (3) Naturally cool to room temperature after the reaction, centrifuge, and remove the upper liquid to obtain a black precipitate. The obtained precipitates were alternately ultrasonically washed twice with deionized water and absolute ethanol respectively, and the obtained samples were dried in a constant temperature drying oven at 70°C for 6 hours to obtai...

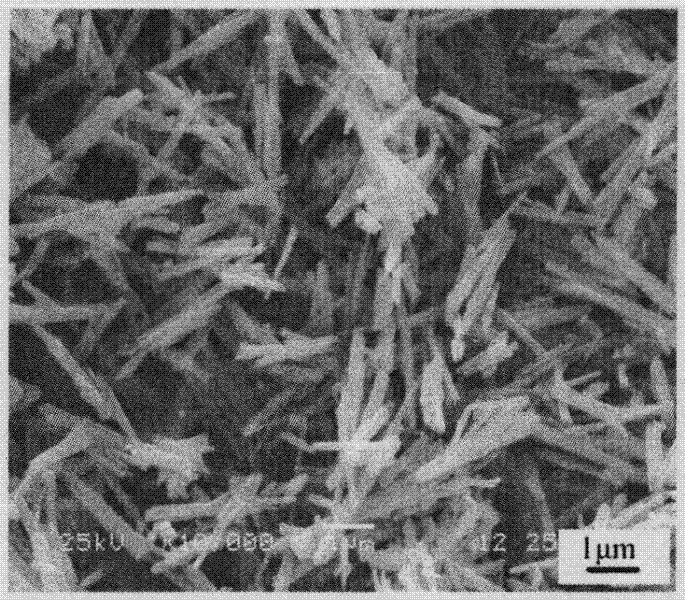

Embodiment 3

[0030] (1) Accurately weigh 1.3g Sb 2 o 3 Added to 30mL 1,2-propanediol (Sb 2 o 3 With 1, the ratio of the amount of substance of 2-propanediol is 1: 92), stir, then add 1g sulfur powder (the amount of substance of sulfur is Sb 2 o 36.9 times of the amount of substance), continue to stir and mix, add surfactant polyethylene glycol 400 (PEG400) 3mL wherein (the amount of substance of polyethylene glycol 400 is Sb 2 o 3 1.9 times the amount of substance), after mixing, the mixed solution was transferred to a three-necked flask.

[0031] (2) Slowly add 1.3 g of sodium borohydride (the amount of sodium borohydride is 1.1 times the amount of sulfur powder) into the mixed solution while stirring magnetically. Heated with an oil bath and refluxed at 170°C for 8 hours.

[0032] (3) Naturally cool to room temperature after the reaction, centrifuge, and remove the upper liquid to obtain a black precipitate. The obtained precipitates were alternately ultrasonically washed 3 times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com