Composite anti-screening agent nanostructured lipid carrier and preparation method thereof

A technology of nanostructured lipids and composite lipids, which can be used in pharmaceutical formulations, cosmetic preparations, and toiletry preparations, etc. It can solve problems such as easy discoloration and easy degradation of avobenzone, increase crystal defects, and improve drug stability. Sexuality, the effect of reducing drug leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The preparation of embodiment 1 composite sunscreen agent nanostructure lipid carrier

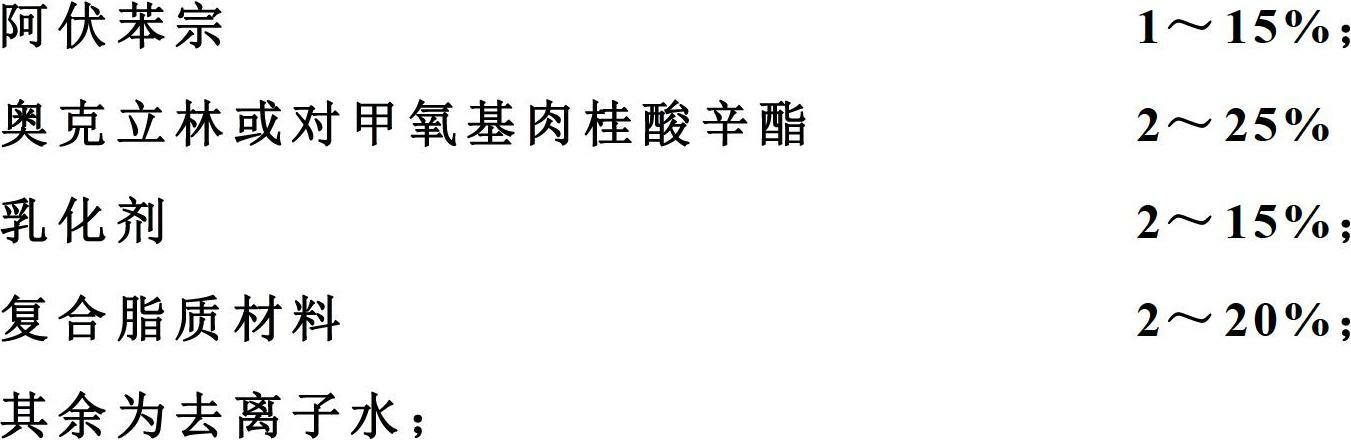

[0039] Composition formula

[0040]

[0041]

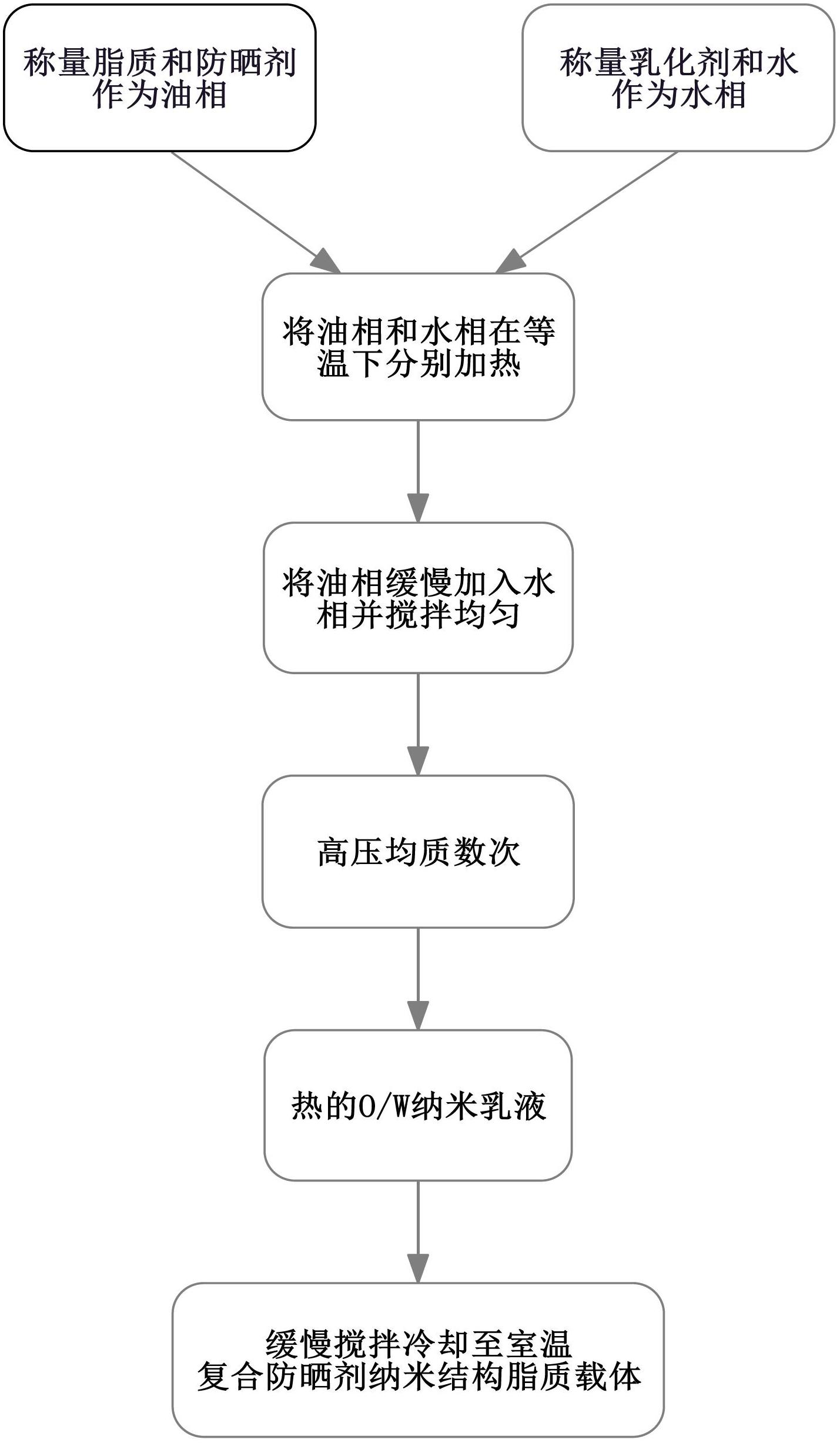

[0042] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0043] 1. Weigh 2.0 grams of cetyl alcohol, 2.0 grams of PEG-75 stearate, 3.5 grams of steareth-20, 2.5 grams of glyceryl stearate, 58.0 grams of deionized water into a beaker, and carry out 70 ℃ Heated in a water bath, and stirred evenly, as the water phase.

[0044] 2. Weigh 5.0 grams of diethyl sebacate, 2.0 grams of glyceryl monostearate, and 15.0 grams of octocrylene, and heat them in a water bath at 70°C.

[0045] 3. After the lipid in the beaker is completely melted, add 10.0 grams of avobenzone, heat and dissolve until completely, as the oil phase.

[0046] 4. Add the oil phase to the water phase and stir evenly. At the same time, turn on the high-pressure homogenizer and preheat it with 75°C deionized water;

[0047] 5. Inject t...

Embodiment 2

[0049] Preparation of Example 2 Composite Sunscreen Nanostructured Lipid Carrier

[0050] Composition formula

[0051]

[0052] Preparation steps:

[0053] 1. Weigh 4.0 grams of glyceryl stearate, 6.0 grams of PEG-100 stearate, and 57.0 grams of deionized water into a beaker, heat in a water bath at 75°C, and stir evenly to serve as the water phase.

[0054] 2. Weigh 3.0 grams of carnauba wax, 5.0 grams of diisopropyl adipate, and 15.0 grams of octyl p-methoxycinnamate, and heat them in a water bath at 75°C.

[0055] 3. After the lipid in the beaker is completely melted, add 10.0 g of avobenzone, heat and dissolve until completely, as the oil phase.

[0056] 4. Add the oil phase to the water phase and stir evenly. At the same time, turn on the high-pressure homogenizer and preheat it with 80°C deionized water;

[0057] 5. Pour the uniformly stirred high-temperature emulsion system into a high-pressure homogenizer, adjust the homogenization pressure to 60MPa, and cycle th...

Embodiment 3

[0059] Preparation of Example 3 Composite Sunscreen Nanostructured Lipid Carrier

[0060] Composition formula

[0061]

[0062] Preparation steps:

[0063] 1. Weigh 1.0 grams of cetyl alcohol, 1.0 grams of PEG-75 stearate, 2.0 grams of steareth-20, 4.5 grams of glyceryl stearate, 2.0 grams of PEG-100 stearate, 61.5 grams Deionized water was put into a beaker, heated in a water bath at 75°C, and stirred evenly to serve as the water phase.

[0064] 2. Weigh 3.0 grams of caprylic capric glycerides, 3.0 grams of carnauba wax, 3.0 grams of glyceryl monostearate, 5.0 grams of octocrylene, and 9.0 grams of octyl methoxycinnamate and heat them in a water bath at 75°C.

[0065] 3. After the lipid in the beaker is completely melted, add 5.0 grams of avobenzone, heat and dissolve until completely, as the oil phase.

[0066] 4. Add the oil phase to the water phase and stir evenly. At the same time, turn on the high-pressure homogenizer and preheat it with 80°C deionized water;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com