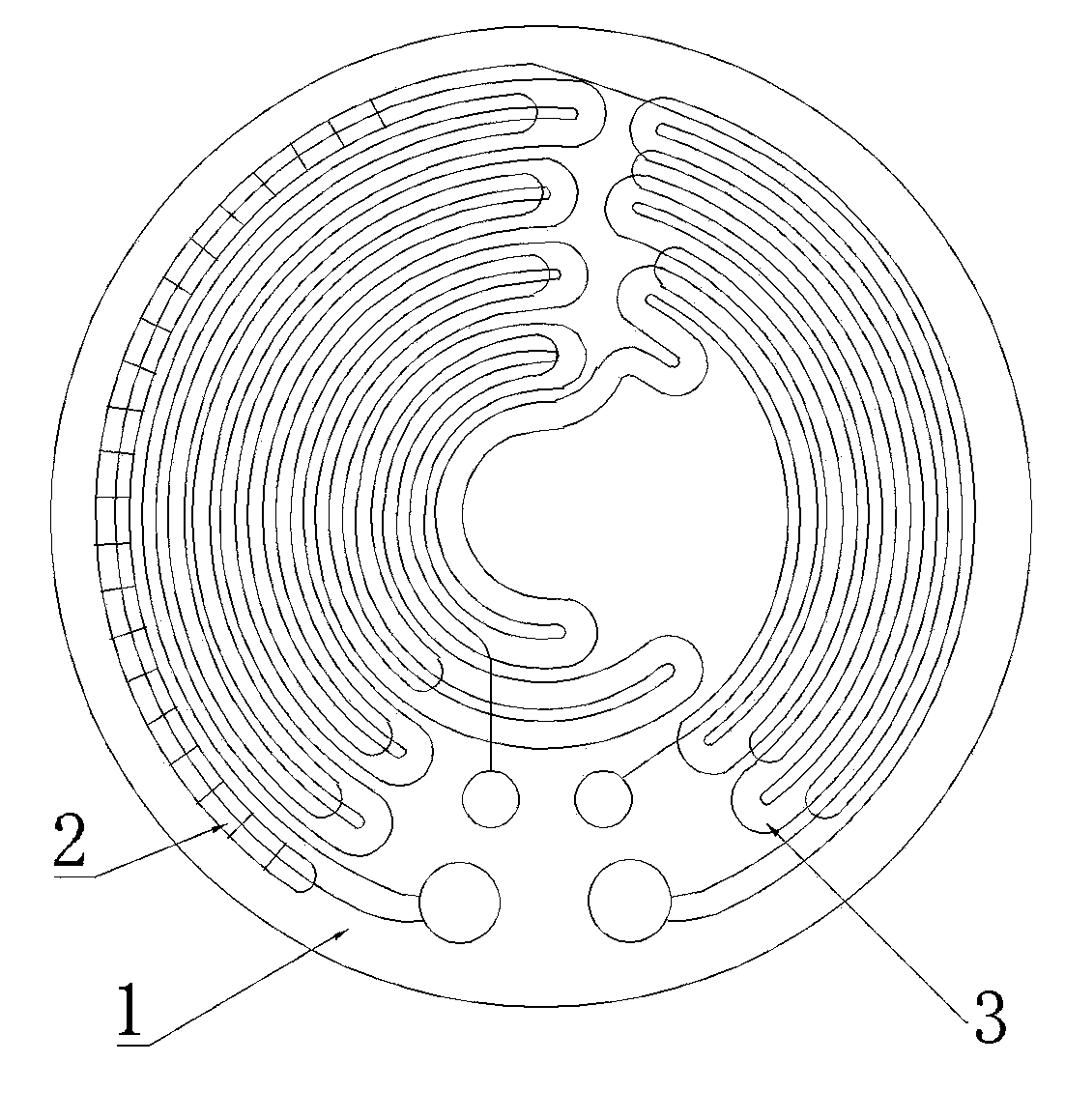

Intelligent electric-heating element with PTC (Positive Temperature Coefficient) rare-earth thick film circuit and preparation method thereof

A rare earth thick film, intelligent electric heating technology, applied in electrical components, heating element materials, electric heating devices, etc., can solve the problems of difficult electric heating field promotion, low component sensitivity, poor manufacturing process, etc., to achieve uniform heating temperature field and graded automatic control , Fast thermal response, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

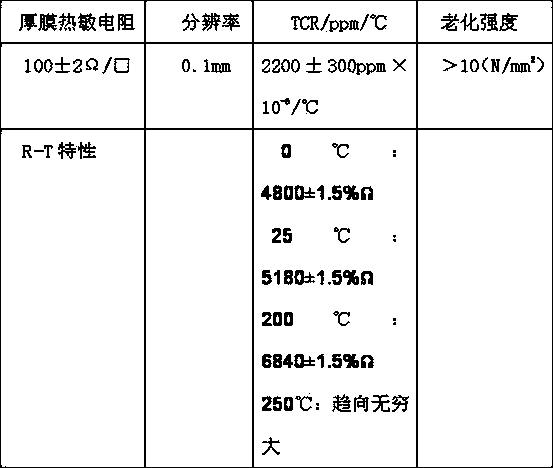

[0035] 1. Preparation method of a series of rare earth electronic pastes

[0036] 1. Preparation of rare earth medium slurry

[0037] The rare earth medium slurry is composed of solid phase components and organic solvent carriers, and its weight ratio is: 65: 35 ~ 85: 15; solid phase components are: Si0 2 ~Al 2 0 3 ~CaO~B 2 o 3 ~La 2 o 3 Rare earth oxide-based glass-ceramics, the weight ratio is: Si0 2 30 ~ 65%, Al 2 0 3 5~26%, CaO 15~38%, B 2 o 3 2 ~16%, La 2 o 3 0.3~15%. co 2 o 3 0.05~6%. The nucleating agent is TiO 2 1 ~ 10%, ZrO: 1 ~ 10%. The solvent carrier ratio is: butyl carbitol 66-89%, tributyl citrate 5-15%, ethyl cellulose 0.5-10%, hydrogenated castor oil 0.1-5%, lecithin 0.1-5%. Rare earth oxides are; lanthanum, cerium, neodymium, promethium, gadolinium, erbium, scandium, yttrium and terbium oxide. Rare earth oxides can be added with different types and different proportions of rare earth oxides according to the experimental mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com