Anti-corrosion magnalium base alloy and preparation method thereof

A magnesium-aluminum-based and alloy technology, applied in the field of magnesium-aluminum-based alloy and its preparation, can solve the problems of weak bonding force between coating and substrate, complicated processing technology, poor wear resistance of coating, etc. Simple, corrosion-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 150g of Al, 15g of Mn, and 335g of Mg. The above-mentioned raw materials are all 99.5% pure metal powder, and the above-mentioned pure metal powder raw materials are pressed into a block with a diameter of 35 mm and a height of 10 mm. , plasma sintering for 5 min to obtain the alloy precursor. The above alloy precursor was wrapped with tantalum foil, melted and kept for 30 min at 10GPa, 1.1Tm (Tm: melting point), and then quickly solidified by blowing nitrogen gas. Then aging for 24 hours under 0.1Tm, the Mg-30Al-3Mn magnesium alloy with high strength and outstanding corrosion resistance can be obtained.

[0025] like figure 1 As shown, after soaking in 3.5 wt% NaCl solution, the corrosion resistance of the Mg-30Al-3Mn alloy obtained in this example is 10 times higher than that of magnesium alloys prepared by other traditional casting methods.

Embodiment 2

[0027] Take 5g of Al, 50g of Cd, and 445g of Mg. The above-mentioned raw materials are all 99.5% pure metal powder, and the above-mentioned pure metal powder raw materials are pressed into a block with a diameter of 25 mm and a height of 20 mm. The alloy precursor was obtained by plasma sintering for 10 min. The above alloy precursor was wrapped with tantalum foil, melted and kept for 30 min at 2 GPa, 1.1 Tm (Tm: melting point), and then quickly solidified by blowing nitrogen gas. Then aging for 2 hours under 0.2Tm, the Mg-1Al-10Cd magnesium alloy with high strength and outstanding corrosion resistance can be obtained.

[0028] like figure 1 As shown, after soaking in 3.5 wt% NaCl solution, the corrosion resistance of the Mg-1Al-10Cd alloy obtained in this example is 12 times higher than that of magnesium alloys prepared by other traditional casting methods.

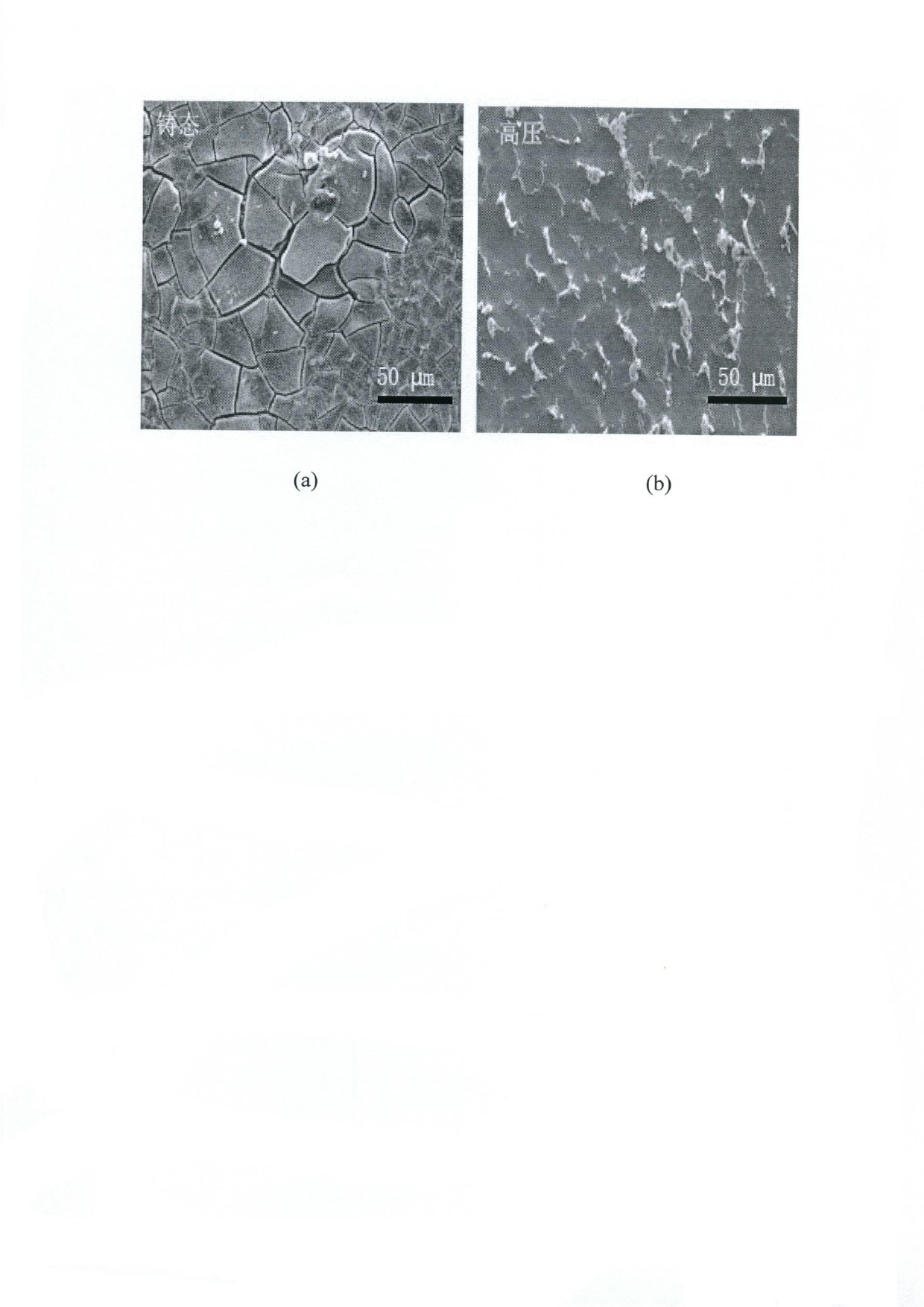

[0029] like figure 2 As shown, compared with the Mg-1Al-10Cd alloy obtained in this example, the dendrite spacing ...

Embodiment 3

[0031] Take 100g of Al, 5g of Mn, 25g of Cd, and 370g of Mg. The above raw materials are all 99.5% pure metal powder, and the above pure metal powder raw materials are pressed into a block with a diameter of 30 mm and a height of 15 mm. The alloy precursor was obtained by plasma sintering under MPa pressure for 8 min. The above alloy precursor was wrapped with tantalum foil, melted and kept for 30 min at 6 GPa, 1.1 Tm (Tm: melting point), and then quickly solidified by blowing nitrogen gas. Then aging for 14 hours at 0.2Tm, the Mg-20Al-1Mn-5Cd magnesium alloy with high strength and outstanding corrosion resistance can be obtained.

[0032] like figure 1 As shown, after soaking in 3.5 wt% NaCl solution, the corrosion resistance of the Mg-20Al-1Mn-5Cd alloy obtained in this example is 11 times higher than that of magnesium alloys prepared by other traditional casting methods.

[0033] like image 3 As shown, the Mg-20Al-1Mn-5Cd alloy obtained in this example is compared with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com