Environment-friendly type liquid fuel and preparation method thereof

A liquid fuel, total volume technology, applied in the field of environment-friendly liquid fuel and its preparation, to achieve the effects of prolonging service life, simple preparation process, and inhibiting corrosion and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 single transesterification reaction

[0038] Respectively transesterify dimethyl carbonate (or ethylene carbonate) and a monohydric alcohol with 2-8 carbon atoms in a tubular transesterification reactor, using zinc acetate as a catalyst, zinc acetate and dimethyl carbonate The weight ratio of ester or ethylene carbonate is (0.1-1): 100, the molar ratio of dimethyl carbonate (or ethylene carbonate) to monohydric alcohol is controlled at 1:2-8, and the reaction temperature is 140-200°C, absolutely The pressure is 2-8MPa, the reaction time is 10-20 minutes, and the dialkyl carbonate mixture is obtained;

[0039] The dialkyl carbonate mixture is distilled under reduced pressure at an absolute pressure of 0.01-0.02MPa and a temperature of 180-200°C, and the corresponding fractions are collected to obtain dicarbonates with different carbon numbers with a volume content of ≥95%. Alkyl esters.

Embodiment 2

[0040] Embodiment 2 mixed transesterification reaction

[0041] After mixing dimethyl carbonate (or ethylene carbonate) with various monohydric alcohols with 2-8 carbon atoms, transesterification is carried out in a tubular transesterification reactor, and other transesterification conditions are the same as in Example 1;

[0042] The dialkyl carbonate mixture is distilled under reduced pressure at an absolute pressure of 0.01-0.02MPa and a temperature of 180-200°C, and the fraction at 80-90°C is collected to obtain a dialkyl carbonate mixture with a carbon number of ≤5 ;Collect the distillate at 125-135°C to obtain a dialkyl carbonate mixture with 6-9 carbon atoms; collect the distillate at 180-200°C to obtain a dialkyl carbonate mixture with 10-17 carbon atoms .

Embodiment 3

[0043] Embodiment 3 deploys gasoline

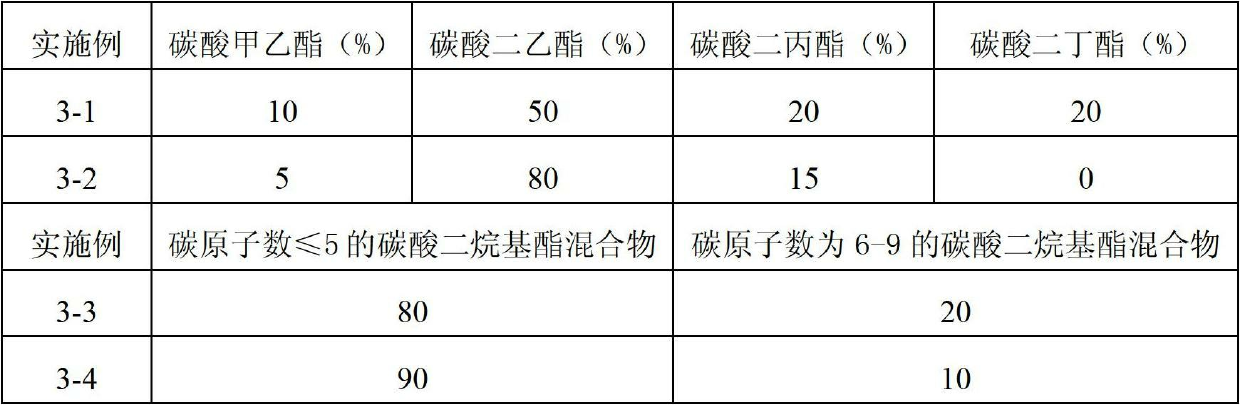

[0044] According to the method described in Example 1, ethyl methyl carbonate, diethyl carbonate, dipropyl carbonate and dibutyl carbonate with volume content ≥ 95% were prepared respectively (ordinary commercially available dialkyl carbonate can also be directly used) , mixed and blended into 3-1 and 3-2 gasoline according to the composition in Table 1;

[0045] According to the method described in Example 2, dimethyl carbonate (or ethylene carbonate) was mixed with ethanol, n-propanol and n-butanol and then transesterified to obtain carbon atoms with a carbon number of ≤ 5 and a carbon number of 6 respectively. -9 and dialkyl carbonate mixtures with 10-17 carbon atoms are mixed and formulated into 3-3 and 3-4 gasoline according to the volume percentage in Table 1;

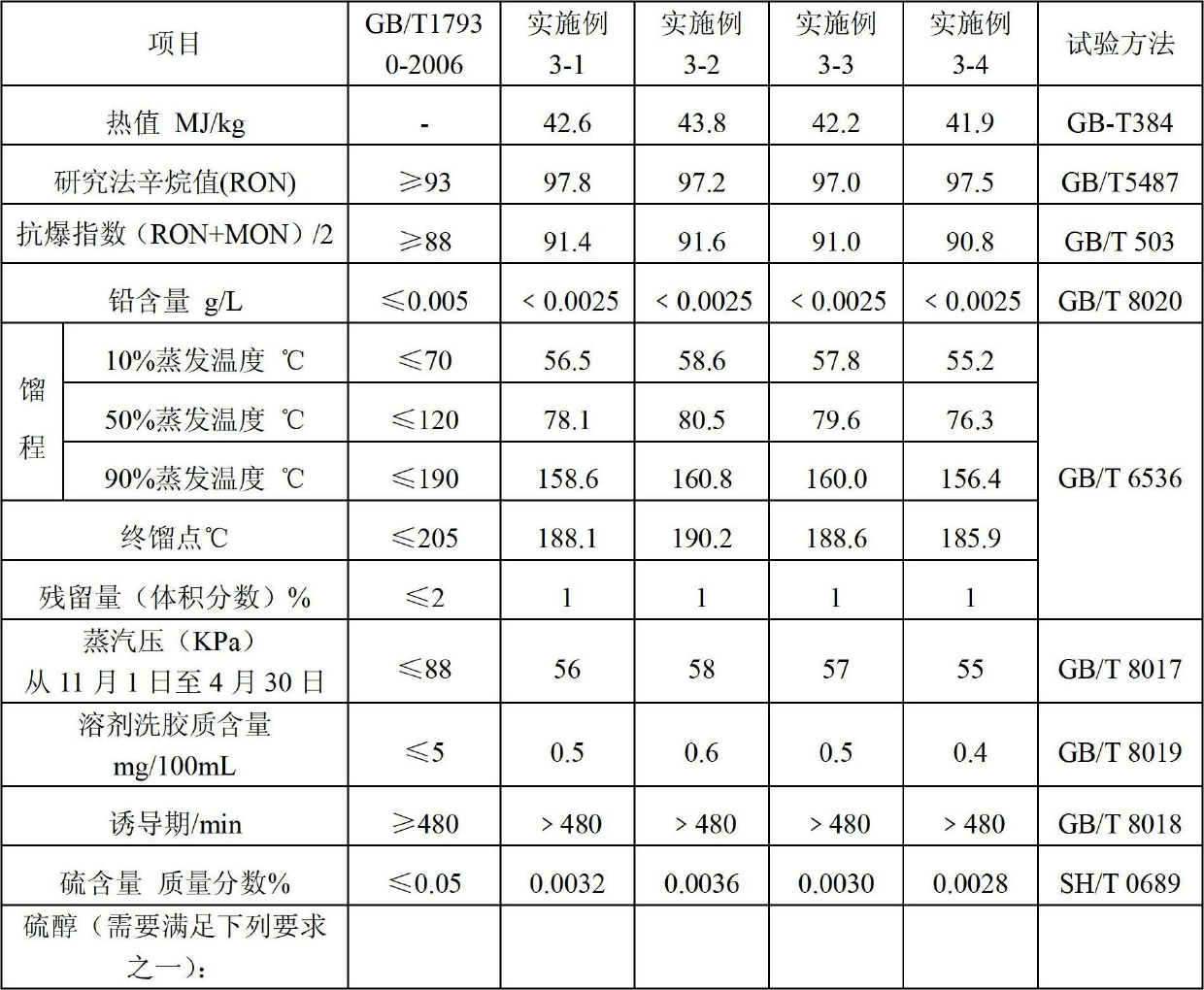

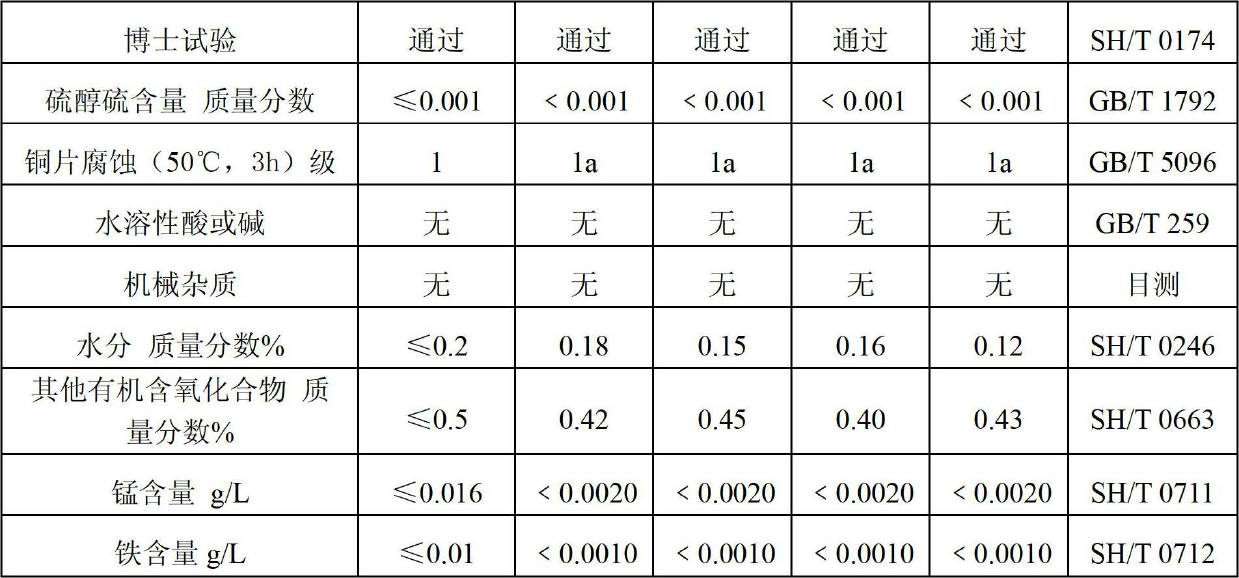

[0046] See Table 2 for the quality detection results of the blended gasoline prepared by the present invention.

[0047] Table 1 Composition and volume content of blended ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com