Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

A sugar solution, ethylene glycol technology, applied in 1, can solve problems such as cumbersome reaction process, achieve the effects of improving economy, high product concentration, and reducing energy consumption for distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

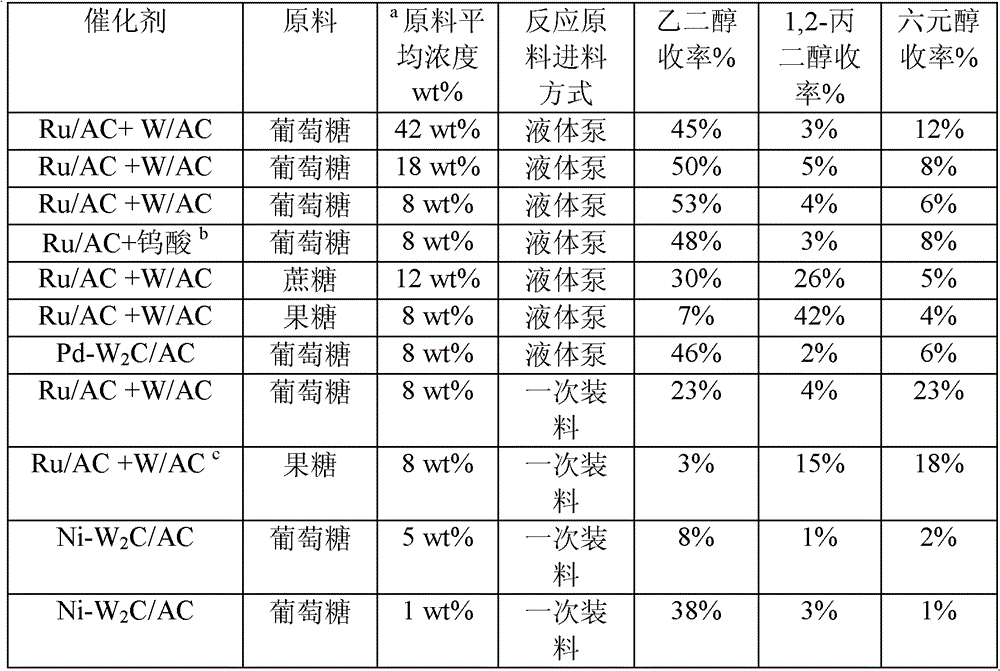

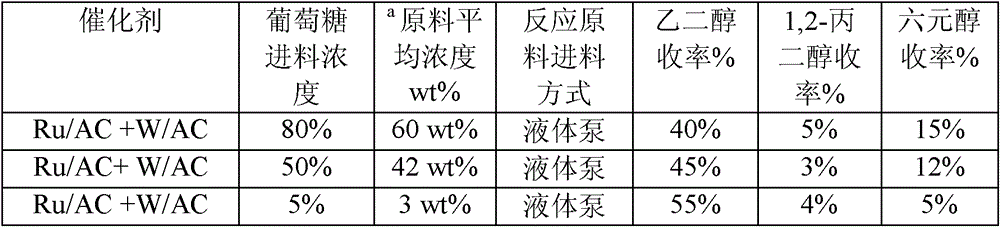

Examples

Embodiment 1

[0019] Preparation of the metal catalyst Ru / AC: impregnate the activated carbon support with ruthenium trichloride aqueous solution, dry at 120°C for 12h, and then reduce it in a hydrogen atmosphere at 500°C for 1h to obtain the catalyst Ru / AC (2wt%Ru).

Embodiment 2

[0021] Preparation of metal catalyst W / AC: impregnate activated carbon support with ammonium metatungstate aqueous solution, dry at 120°C for 12h, and then reduce in hydrogen atmosphere at 700°C for 1h to obtain catalyst W / AC (30wt%W).

Embodiment 3

[0023] Ni-W 2 C / AC catalyst preparation: References Angew.Chem.Int.Ed.2008, 47,8510-8513, ammonium metatungstate and nickel nitrate are made into a mixed solution according to the ratio of tungsten / nickel weight ratio of 15:1, wherein , the mass volume concentration of ammonium metatungstate is 0.4g / ml. Then, the mixed solution was impregnated with activated carbon support (AC). After oven drying at 120 °C for 12 h, the catalyst precursor was placed in H 2 The temperature-programmed carbothermal reaction was carried out in the atmosphere. The specific reaction process was as follows: 2.0 g of the precursor was heated from room temperature to 400 °C in a quartz reaction tube for 1 h, then raised to 700 °C at 1 °C / min and kept for 1 h for carbonization. The hydrogen flow rate was 100ml / min. Obtained Ni-W with tungsten loading of 30wt% and nickel loading of 2wt% 2 C / AC catalyst, expressed as Ni-W 2 C / AC (2wt%Ni-30wt%W 2 C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com