Carbon/carbon composite ultrahigh temperature anti-oxidation coating and preparation process thereof

A carbon composite material and anti-oxidation coating technology, applied in the field of anti-oxidation inorganic materials, can solve the problems of pores in the coating, difficulty in preparing stoichiometric carbide phases, and poor ultra-high temperature oxidation resistance of multi-layer coatings, etc., to achieve High bonding strength, excellent ultra-high temperature oxidation resistance, and the effect of improving ultra-high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The carbon / carbon composite ultra-high temperature anti-oxidation coating of this embodiment is composed of the following components in volume percentage: ZrB 2 70%, HfC 5%, SiC 10%, TiB 2 7%, Sc 2 o 3 8%.

[0035] The preparation method of the present embodiment is as follows:

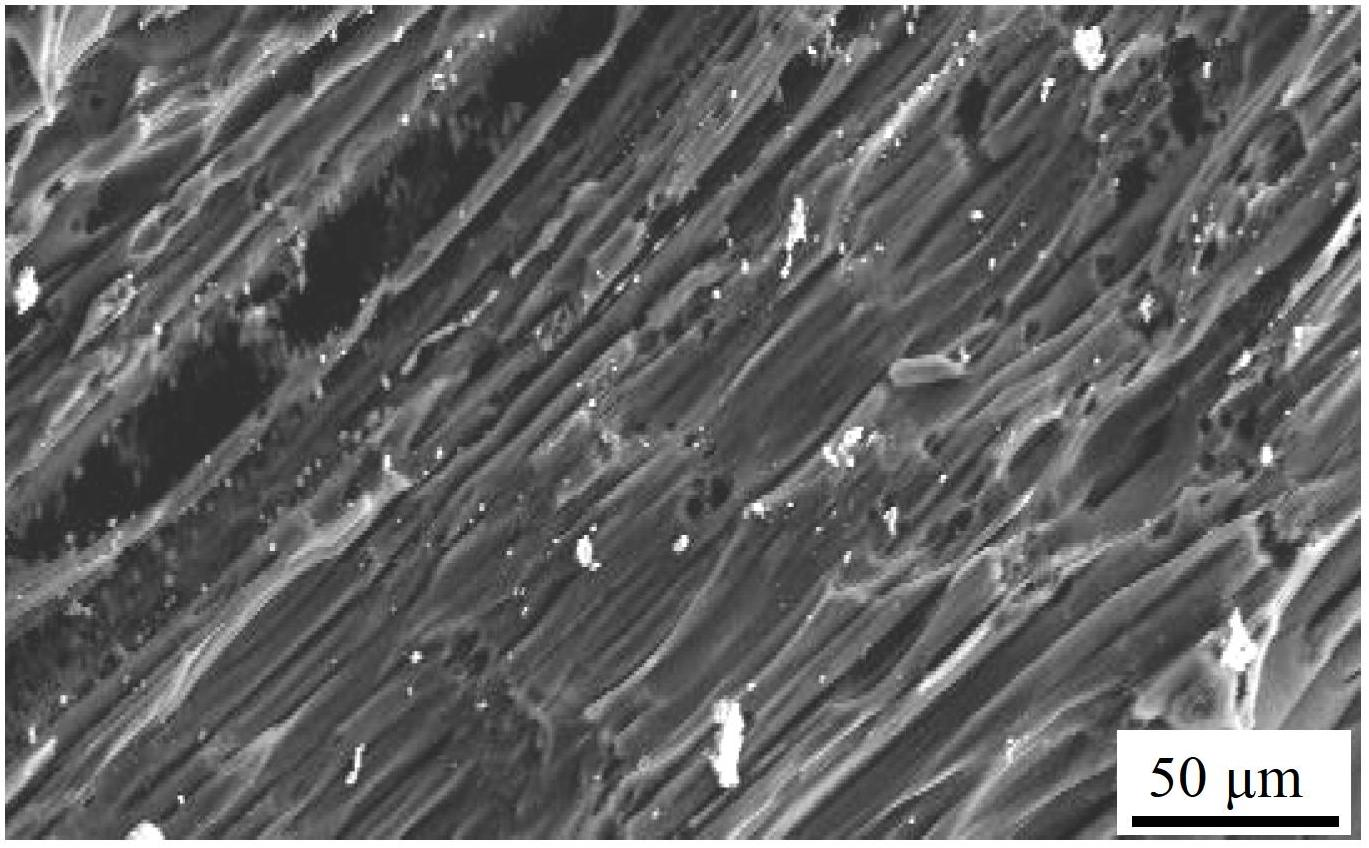

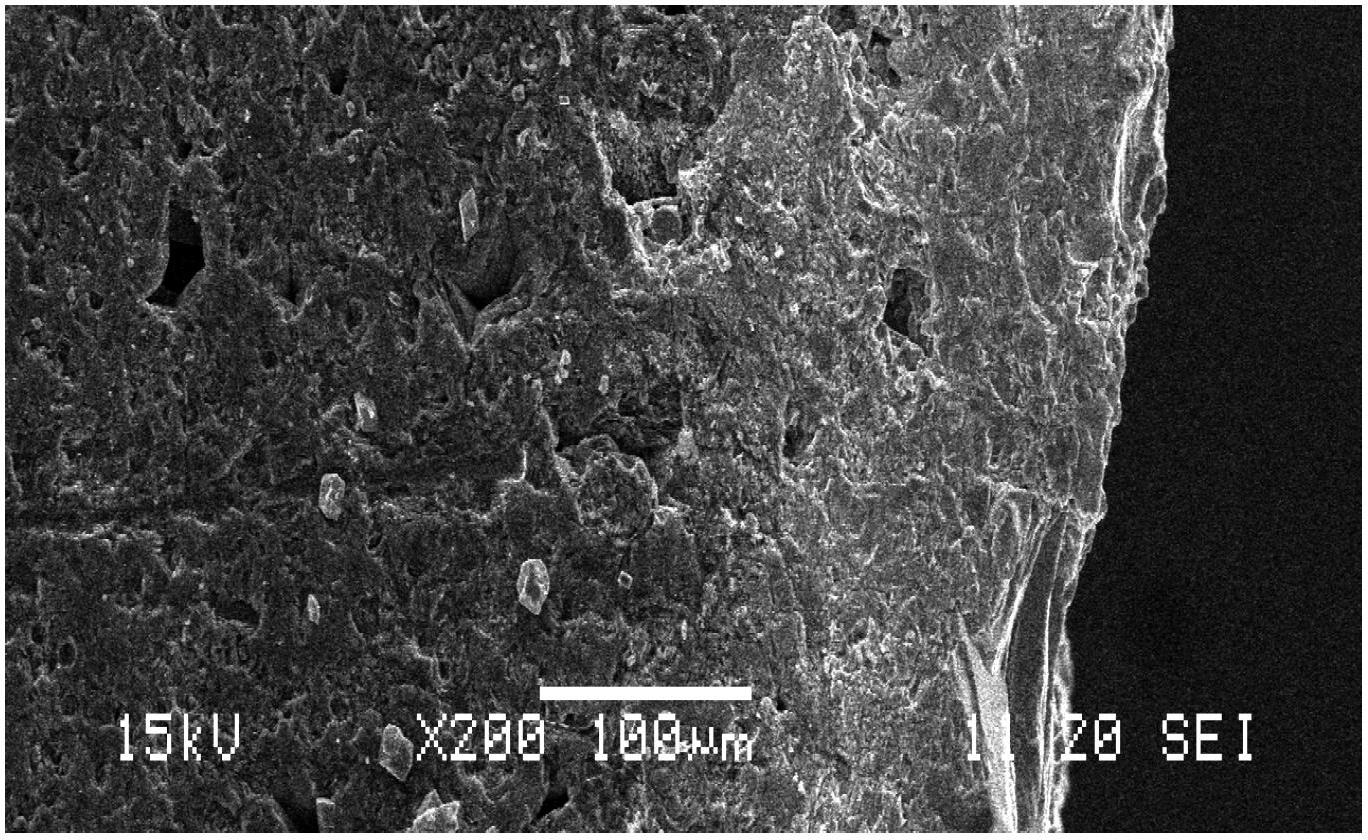

[0036] Step 1. After polishing the carbon / carbon composite material with No. 400, No. 600, No. 800 and No. 1200 water-grinding sandpaper in sequence, ultrasonically clean it in absolute ethanol, and then put it into an oven for drying;

[0037] Step two, ZrB 2 Powder, HfC powder, SiC powder, TiB 2 Powder, Sc 2 o 3 After the powder is mixed by volume percentage, it is put into a ball mill jar with the polyvinylpyrrolidone-ethanol solution in a mass ratio of 1:2, and ball milled for 48 hours to obtain a slurry; the mass fraction of polyvinylpyrrolidone in the polyvinylpyrrolidone-ethanol solution is 20%; the average particle size of each powder in the above is: ZrB 2 2μm, HfC 2μm, Si...

Embodiment 2

[0043] The carbon / carbon composite ultra-high temperature anti-oxidation coating of this embodiment is composed of the following components in volume percentage: ZrB 2 67%, HfC 6%, SiC 11%, TiB 2 8%, Sc 2 o 3 8%.

[0044] The preparation method of the present embodiment is as follows:

[0045] Step 1. After polishing the carbon / carbon composite material with No. 400, No. 600, No. 800 and No. 1200 water-grinding sandpaper in sequence, ultrasonically clean it in acetone, and then put it in an oven to dry;

[0046] Step two, ZrB 2 Powder, HfC powder, SiC powder, TiB 2 Powder, Sc 2 o 3 After the powder is mixed according to the volume percentage, it is put into a ball mill jar for 64 hours with the polyvinylpyrrolidone-ethanol solution at a mass ratio of 1:5 to obtain a slurry; the mass fraction of polyvinylpyrrolidone in the polyvinylpyrrolidone-ethanol solution is 24 %; the average particle size of each powder is: ZrB 2 1μm, HfC 1μm, SiC 0.05μm, TiB 2 1 μm, Sc 2 ...

Embodiment 3

[0051] The carbon / carbon composite ultra-high temperature anti-oxidation coating of this embodiment is composed of the following components in volume percentage: ZrB 2 63%, HfC 7%, SiC 12%, TiB 2 9%, Sc 2 o 3 9%.

[0052] The preparation method of the present embodiment is as follows:

[0053] Step 1. After polishing the carbon / carbon composite material with No. 400, No. 600, No. 800 and No. 1200 water abrasive paper in sequence, ultrasonically clean it in deionized water, and then put it in an oven for drying;

[0054] Step two, ZrB 2 Powder, HfC powder, SiC powder, TiB 2 Powder, Sc 2 o 3 After the powder is mixed by volume percentage, it is put into a ball mill jar with the polyvinylpyrrolidone-ethanol solution at a mass ratio of 1:3, and ball milled for 48 hours to obtain a slurry; the mass fraction of polyvinylpyrrolidone in the polyvinylpyrrolidone-ethanol solution is 20%; the average particle size of each powder is: ZrB 2 2μm, HfC 2μm, SiC 0.5μm, TiB 2 2μm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com