Method for preparing ammonium fluorosilicate by utilizing fluorine-containing white slime in anhydrous hydrogen fluoride production

A technology of anhydrous hydrogen fluoride and ammonium fluorosilicate, applied in the chemical industry, can solve the problems of clogging, poor fluorine absorption effect, and large silica precipitation, etc., and achieve the effect of simple process flow, less equipment, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

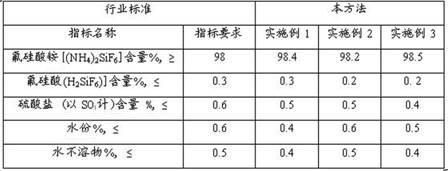

Examples

Embodiment 1

[0026] A method for preparing ammonium fluorosilicate by utilizing fluorine-containing silicon slag in the production of anhydrous hydrogen fluoride, comprising the steps of:

[0027] (1) Dissolution reaction: In a dissolution reaction kettle with a stirrer and a heating device, according to SiO 2 The calculated molar ratio of ammonium fluoride to fluorine-containing silicon slag is 12, add fluorine-containing silicon slag and ammonium fluoride solution with a mass concentration of 40%, under the conditions of temperature 90-100°C and pressure -15--10kpa A dissolution reaction occurs until the silicon slag is completely dissolved to obtain a high-concentration solution of ammonium fluorosilicate and ammonium fluoride. The ammonia and water vapor produced by the dissolution reaction are cooled to below 30°C to obtain dilute ammonia water and ammonia gas, which are sent to the phosphate fertilizer plant for fertilizer processing.

[0028] (2) Filtration: Filtrate the solution i...

Embodiment 2

[0035] A method for preparing ammonium fluorosilicate by utilizing fluorine-containing silicon slag in the production of anhydrous hydrogen fluoride, comprising the steps of:

[0036] (1) Dissolution reaction: In a dissolution reaction kettle with a stirrer and a heating device, according to SiO 2 The calculated ammonium fluoride and fluorine-containing silicon slag molar ratio is 9, adding fluorine-containing silicon slag and the mixed mother liquor obtained in step (5) and (6) of embodiment 1 and the ammonium fluoride solution with a mass concentration of 45% added, The dissolution reaction takes place under the conditions of temperature 95-105°C and pressure -12-8kpa until all the silicon slag is dissolved to obtain a mixed solution of high-concentration ammonium fluorosilicate and ammonium fluoride. The ammonia and water vapor produced by the dissolution reaction are cooled to below 30°C to obtain dilute ammonia water and ammonia gas, which are sent to the phosphate fertil...

Embodiment 3

[0044] A method for preparing ammonium fluorosilicate by utilizing fluorine-containing silicon slag in the production of anhydrous hydrogen fluoride, comprising the steps of:

[0045] (1) Dissolution reaction: the method is the same as step (1) in Example 2. Wherein, the dissolution reaction conditions are: temperature 100-108° C., pressure -5-0 kpa. The proportion of fluorine-containing silicon slag and ammonium fluoride is: SiO 2 The calculated molar ratio of ammonium fluoride to fluorine-containing silicon slag is 15.

[0046] (2) Filtration: the method is the same as step (2) of Example 1;

[0047] (3) Heat exchange: the method is the same as step (3) of embodiment 1. Among them, the hot mixed solution of ammonium fluorosilicate and ammonium fluoride is heated to 70°C through indirect heat exchange;

[0048](4) Crystallization by cooling: the method is the same as step (4) of Example 1. Among them, the cooling medium is circulating cooling water, and the mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com