Epoxy emulsion modified quick repair mortar for concrete roads and bridges and preparation method for mortar

A technology of epoxy emulsion and repair mortar, which is applied in the field of chemical building materials, can solve the problems of slow development of repair mortar or concrete early strength, difficulty in meeting the strength index requirements at the same time, and difficulty in preparing quick repair materials, etc., so as to achieve operability in construction The effect of prolonged time, improved curing rate, and good early hardening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

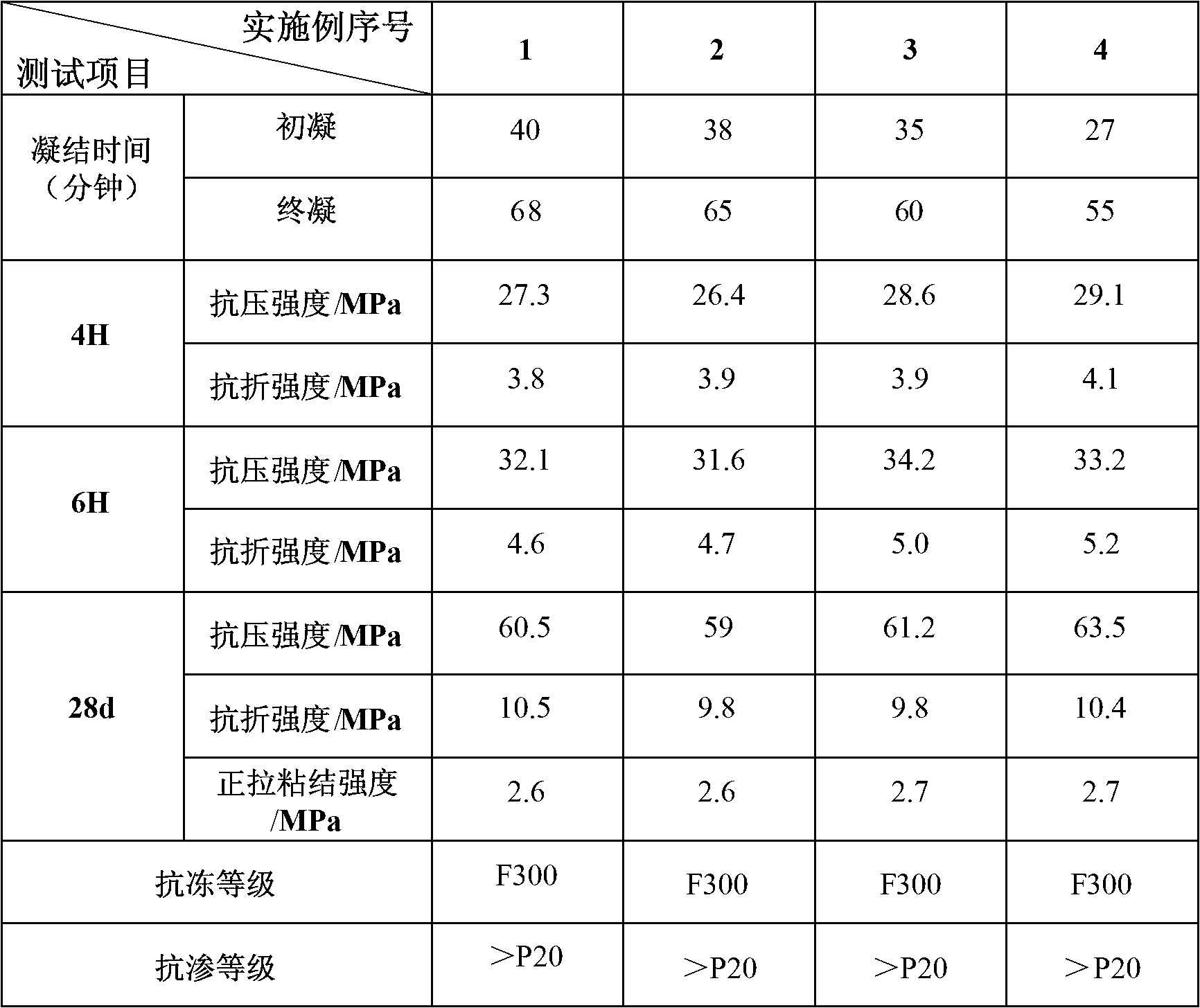

Examples

Embodiment 1

[0044] 1) Preparation of component A: add 100 parts of epoxy resin E-44, 10 parts of acryl glycidyl ether, 15 parts of Qishi toughening agent QS-BE, and 0.1 part of silicone defoamer into the reaction kettle in sequence , stir for 5-10 minutes to obtain component A, pack and store;

[0045] 2) Preparation of component B: 100 parts of water-based epoxy curing agent GCA01 produced by Shanghai Lujia Water-based Coatings Co., Ltd. (active ingredient content: 50wt%, the rest is water), 5 parts of DMP-30, and coupling agent KH 1 part of -550, add to the reaction kettle one by one, stir for 3-5 minutes to obtain component B, pack and store;

[0046] 3) Preparation of component C: 100 parts of rapid-hardening sulfoaluminate cement, 200 parts of a mixture of 40-70 mesh quartz sand and 20-40 mesh quartz sand in a mass ratio of 4:1, 20 parts of metakaolin, and Luoyang 15 parts of calcium sulfate whiskers with an average diameter of 1-8 μm and an average length of 50-200 μm produced by L...

Embodiment 2

[0050] 1) Preparation of component A: Add 100 parts of epoxy resin E-51, 5 parts of acryl glycidyl ether, 15 parts of Qishi toughening agent QS-BE, and 0.1 part of silicone defoamer into the reaction kettle in sequence , stir for 5-10 minutes to obtain component A, pack and store;

[0051] 2) Preparation of component B: Add 100 parts of water-based epoxy curing agent GCA01, 5 parts of DMP-30, and 1 part of coupling agent KH-550 into the reaction kettle in sequence, and stir for 3-5 minutes to obtain component B. packaging storage;

[0052] 3) Preparation of component C: 100 parts of rapid-hardening sulfoaluminate cement, 200 parts of a mixture of 40-70 mesh quartz sand and 20-40 mesh quartz sand in a mass ratio of 4:1, 20 parts of metakaolin, sulfuric acid Add 15 parts of calcium whiskers, 0.35 parts of a mixture of aluminum sulfate and calcium fluoride with a mass ratio of 1:1, 0.2 parts of boric acid, and 0.2 parts of polycarboxylate superplasticizer into the reaction kettl...

Embodiment 3

[0056] 1) Preparation of component A: add 100 parts of epoxy resin NPEF170, 15 parts of KISS toughening agent QS-BE, and 0.1 part of silicone defoamer into the reaction kettle in sequence, and stir for 5-10 minutes to obtain A Components, packaging and storage;

[0057] 2) Preparation of component B: Add 100 parts of water-based epoxy curing agent GCA01, 5 parts of DMP-30, and 1 part of coupling agent KH-550 into the reaction kettle in sequence, and stir for 3-5 minutes to obtain component B. packaging storage;

[0058] 3) Preparation of component C: 100 parts of rapid-hardening sulfoaluminate cement, 200 parts of a mixture of 40-70 mesh quartz sand and 20-40 mesh quartz sand in a mass ratio of 4:1, 20 parts of metakaolin, sulfuric acid Add 15 parts of calcium whiskers, 0.35 parts of a mixture of aluminum sulfate and calcium fluoride with a mass ratio of 1:1, 0.2 parts of boric acid, and 0.2 parts of polycarboxylate superplasticizer. Get component C, pack and store;

[0059...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com