LED (Light-Emitting Diode) lamp with heat radiation structure

A technology of LED lamps and heat dissipation structures, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problems of dissipating heat, increasing heat dissipation area, and unable to ensure smooth airflow, etc. Achieve the effect of improving service life and improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

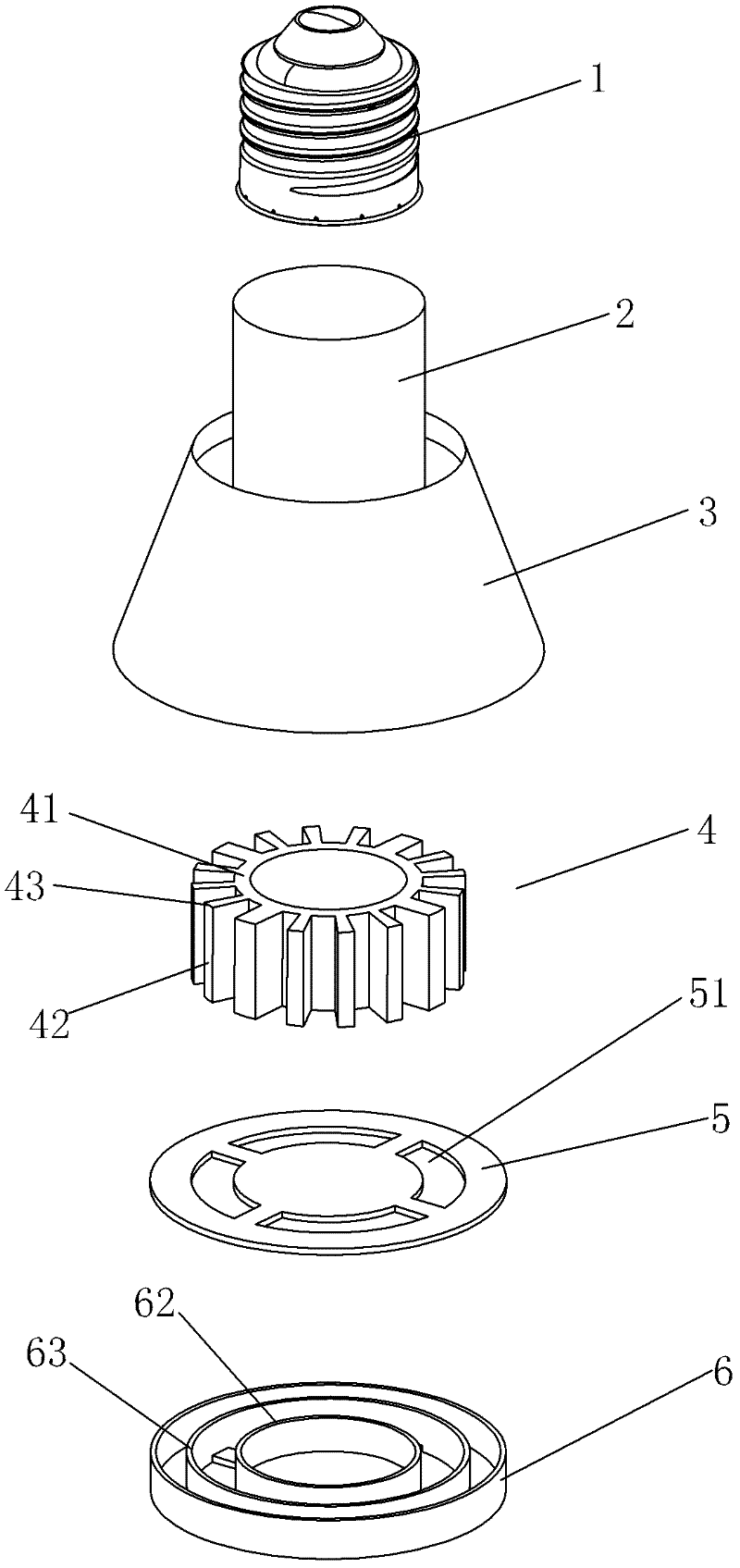

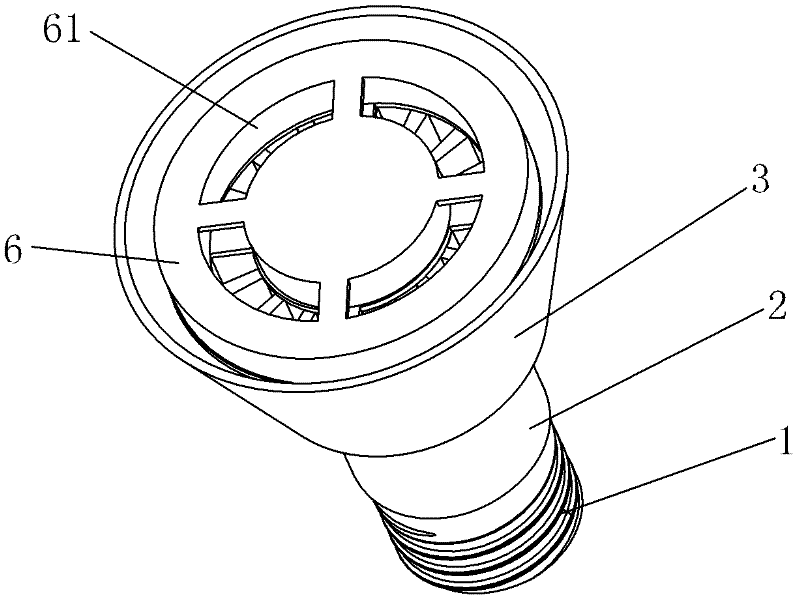

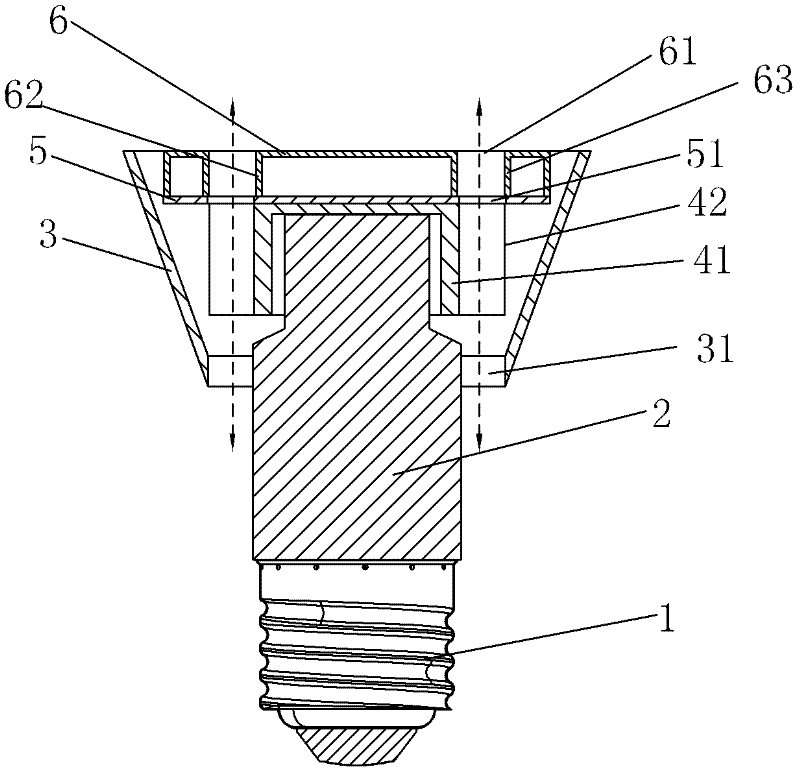

[0028] See Figure 1-Figure 3 As shown, an LED lamp with a heat dissipation structure of the present invention includes a lamp holder 1, a power board, a power board fixing cover 2, a lamp cup 3, a light source board 5 equipped with an LED light source, a lens 6 and a radiator 4. Wherein, radiator 4 is metal material, such as aluminum material or copper material etc., and it comprises hollow cylinder 41 and a plurality of cooling fins 42 that are square respectively; One end of cylinder 41 is closed, and the other end is open (here, The closed end refers to the end near the light source plate, and the open end refers to the end near the lamp cap), and a plurality of heat dissipation fins 42 are distributed on the outer wall circumference of the cylinder 41 at intervals (here, each heat dissipation fin 42 and the cylinder 41 form a connected together). The lamp cup 3 and the power board fixing cover 2 are respectively made of polymer insulating materials, wherein, both ends of...

Embodiment 2

[0036] A kind of LED lamp with heat dissipation structure of the present invention, please refer to Figure 4 , Figure 5 As shown, the difference from Embodiment 1 is that the end of the light source board 5 is located at the inner end 44 of each cooling fin of the radiator 4 along the circumference. Since the light source board 5 is circular, in other words, the light source board The radius of 5 is equal to the distance between the center of the radiator 4 and the inner end 44 of its cooling fins. In this way, the light source board 5 will not block one end of each heat conduction cavity formed by the radiator 4 and the lamp cup 3, that is, one end of each heat conduction cavity formed by the radiator 4 and the lamp cup 3 only needs to pass through the corresponding first process. The air holes 61 can form vertical communication with the outside world.

[0037] In the second embodiment, the lens 6 is also provided with the same first annular side wall 62 and second annula...

Embodiment 3

[0039] A kind of LED lamp with heat dissipation structure of the present invention, please refer to Figure 6-Figure 9 As shown, it differs from Embodiment 1 in that each heat dissipation fin 42 of the heat sink 4 is petal-shaped respectively, and a circular sheet 45 is used as a carrier: the plurality of heat dissipation fins 42 are arranged along the circular sheet. The circumference of 45 is distributed on the end surface of one side at intervals, that is, one end of each cooling fin 42 is integrally connected or fixedly connected to one side end surface of the circular sheet 45; the light source board 5 is assembled on the circular sheet 45. On the other end surface of the sheet 45, and between the light source board 5 and the circular sheet 45 is filled with thermal paste, so that the two form close contact; the circumference of the circular sheet 45 is also provided with a number of third air holes at intervals 44, and each third air hole 44 corresponds to each of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com