Organic electronic devices, compositions, and methods

A composition and device technology, applied in the direction of electrical solid devices, electrical components, semiconductor devices, etc., to achieve the effect of high efficiency and high power conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0184] Example 1: Preparation of patterned silver nanowires disposed on a substrate

[0185] An aqueous coating solution obtained from Cambrios Technologies Corporation was prepared containing silver nanowires, hydroxypropylmethylcellulose (HPMC), Triton X-100, and water. Silver-coated glass substrates were prepared using clear Eagle 2000 glass supplied by Coresix Precision Glass Inc. The glass size is 152.4mm×152.4mm. The glass was pretreated with UV ozone for 10 minutes. The substrates were prepared using a Headway Research Inc. spin coater Model #PWM32-PS-CB15PL. Use a recessed chuck to obtain a uniform coating. On a spin coater rotating at 500 rpm, 10 ml of the coating solution was dispensed on the glass substrate for 60 seconds. The coating was then dried in a convection oven at 50°C for 2 minutes and baked on a hot plate at 180°C for 90-120 seconds. The sheet resistance of the coating was measured to be 15-17 ohms / sq (measured by a Delcom 717B conductivity monitor...

Embodiment 2

[0188] Example 2: Coating of silver nanowire substrates with PLEXCORE OC HIL A formulation

[0189] Coating a silver coating patterned as described in Example 1 with the HIL material prepared in Example 5 produced a non-uniform hazy film on top of the silver nanowire coating. Dilute the HIL with 3 parts by weight: 2 parts by weight methanol. The diluted formulation was spin-coated on the patterned film of Example 1 at 1000 rpm for 30 seconds. This was followed by a drying step at 50°C for 5 minutes and baking at 160°C for 25-30 minutes. This produced a coating of 70-80 nm as measured by a surface profilometry tool. The combined transmittance of the conductive coating and the HIL topcoat was measured to be 86% for the film only.

Embodiment 3

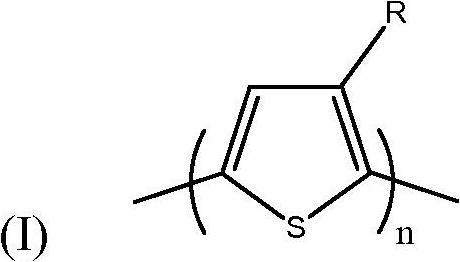

[0190] Embodiment 3: preparation active layer ink

[0191] PLEXCORE P3HT was prepared as described in US Patent Publication 2008 / 0319207. An ink was prepared from P3HT and a fullerene derivative by adding 542 mg of solid to 23.5 g of 1,2-dichlorobenzene. The ink was stirred at about 60°C for 2 hours and then allowed to cool.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com