Fixed-length shear blade and manufacturing method thereof

A manufacturing method and scissor blade technology, applied in the field of metallurgical machinery blades, can solve the problems affecting product shearing quality, production cost and production efficiency, rapid cutting edge wear, chipping, slump, short blade service life, etc. Reasonable quantity and distribution, the effect of reducing residual stress and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

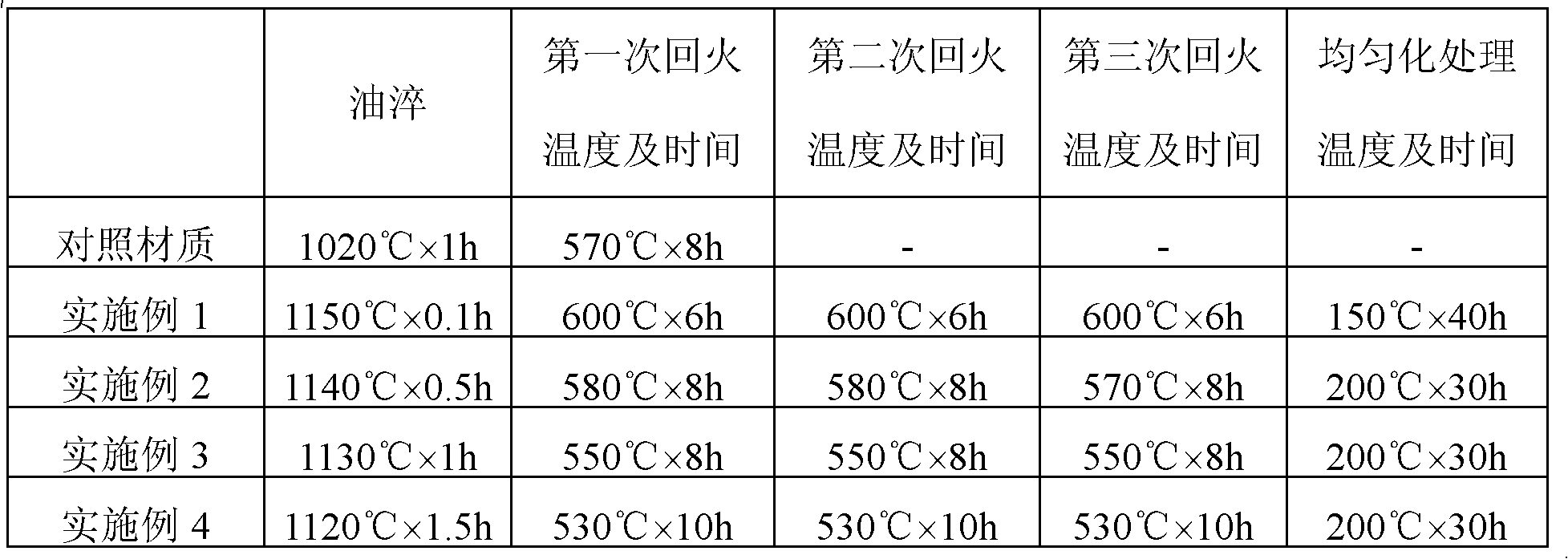

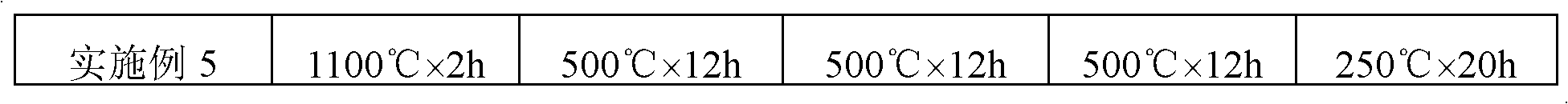

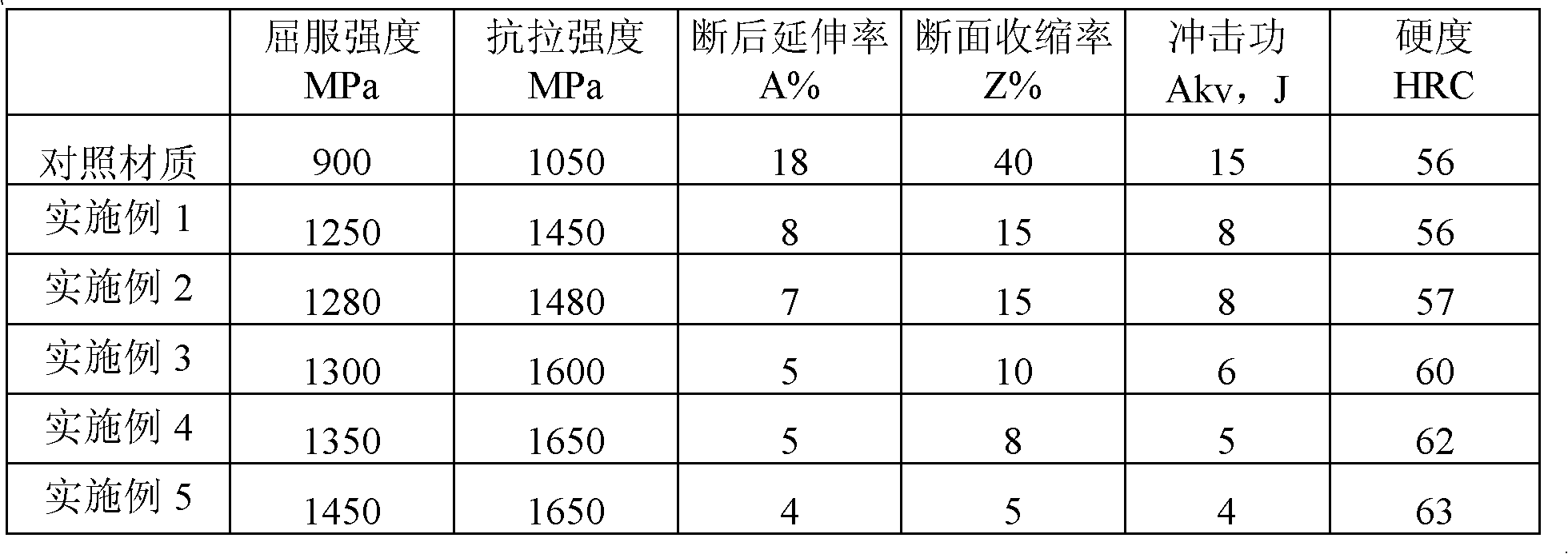

[0013] The present invention will be specifically described below with reference to Examples 1-5.

[0014] Now implement the scissors to length of the present invention respectively by chemical composition shown in table 1.

[0015] Table 1 contrast material and the chemical composition (wt.%) of the scissors to length of the present invention

[0016]

C

Si

mn

Cr

Mo

V

P

S

0.50

0.90

0.30

5.00

0.90

0.80

0.023

0.006

Example 1

1.00

0.60

0.20

6.50

4.00

3.50

0.012

0.005

Example 2

0.90

0.80

0.30

7.00

3.50

3.00

0.014

0.005

Example 3

0.85

1.00

0.40

7.00

3.00

2.50

0.012

0.007

Example 4

0.80

1.20

0.40

7.50

3.00

2.00

0.013

0.005

Example 5

0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com