Method for preparing lithium ion battery anode material with concentration gradient

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, circuits, electrical components, etc., to achieve high stability, improved electrochemical performance, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

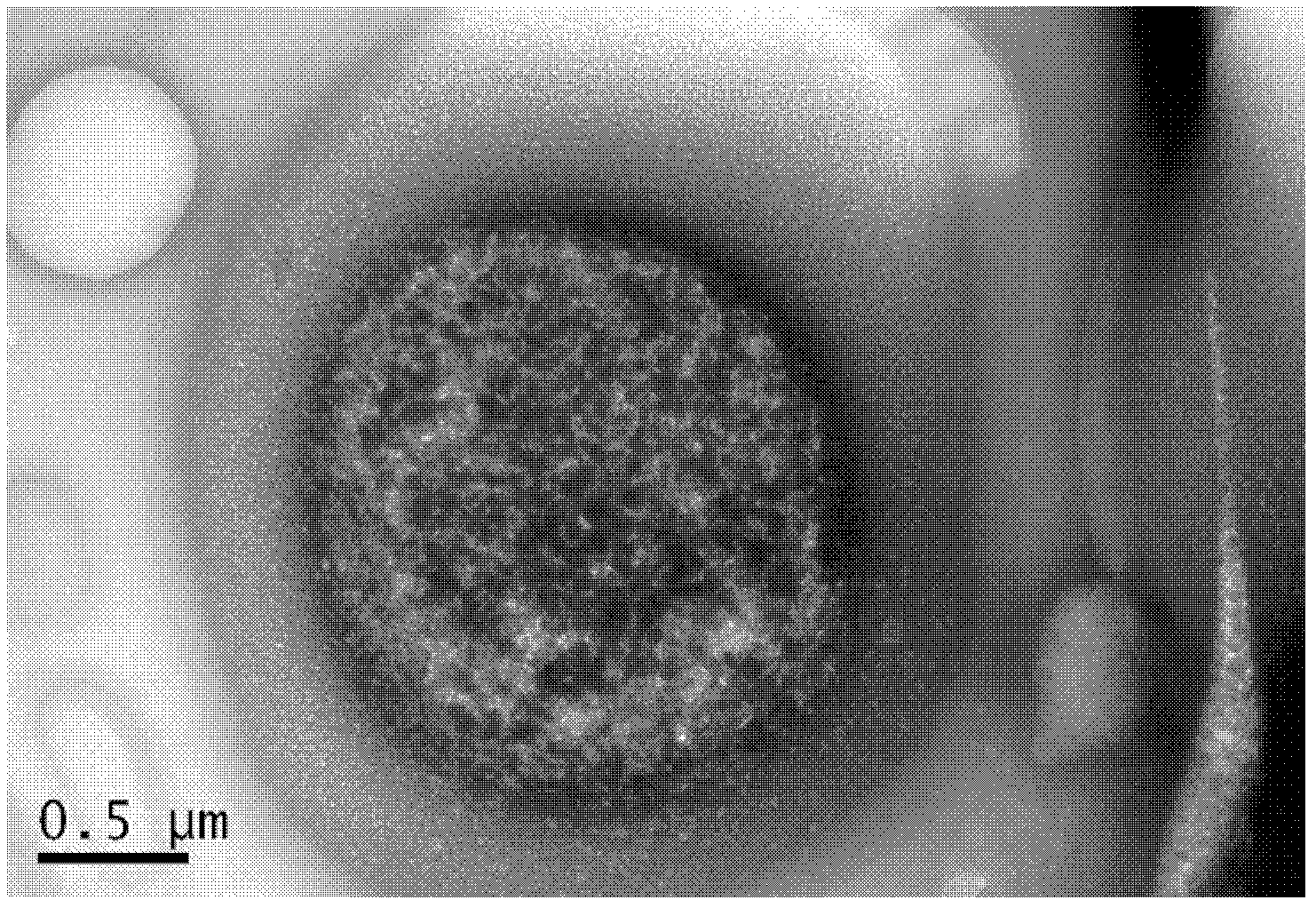

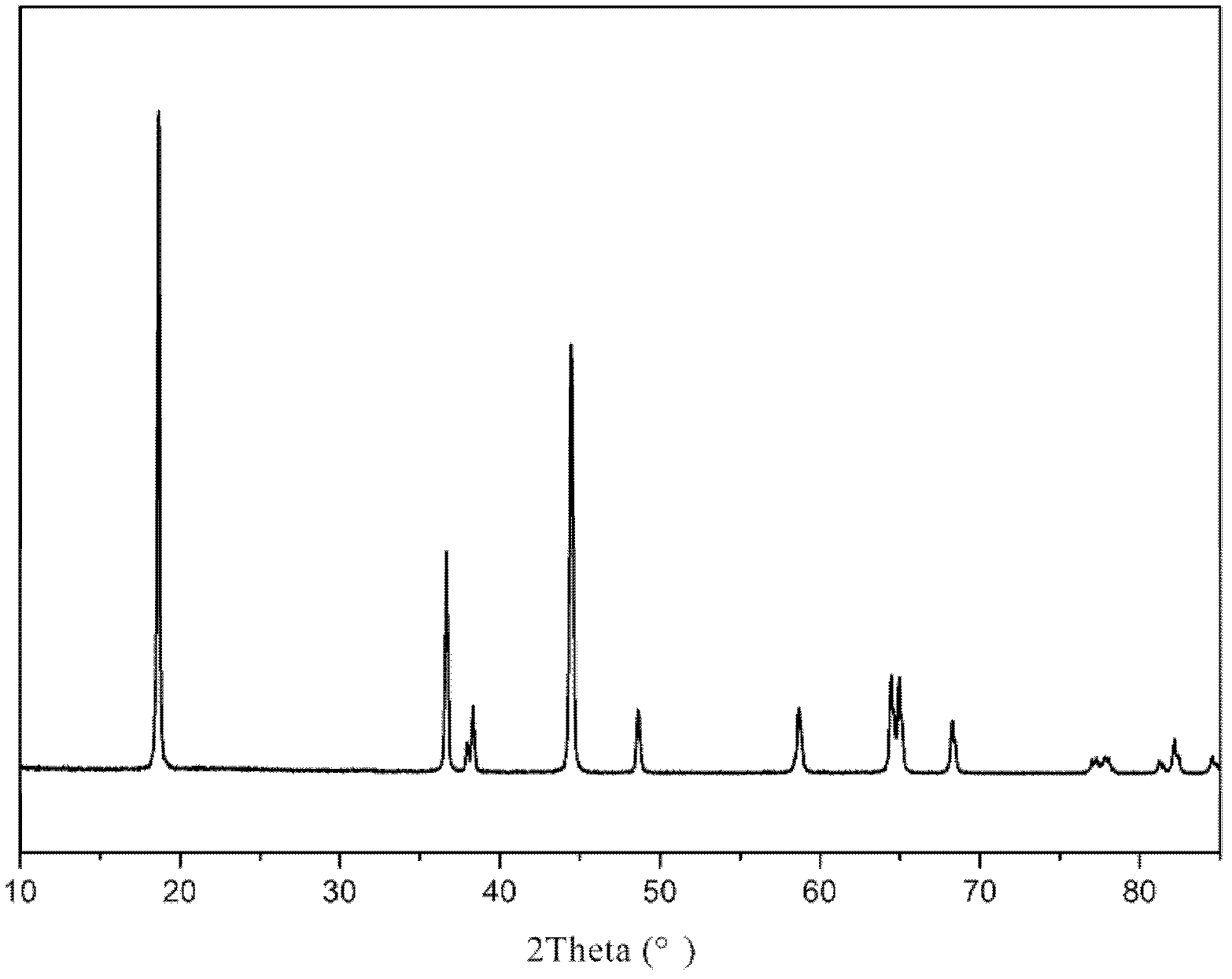

Image

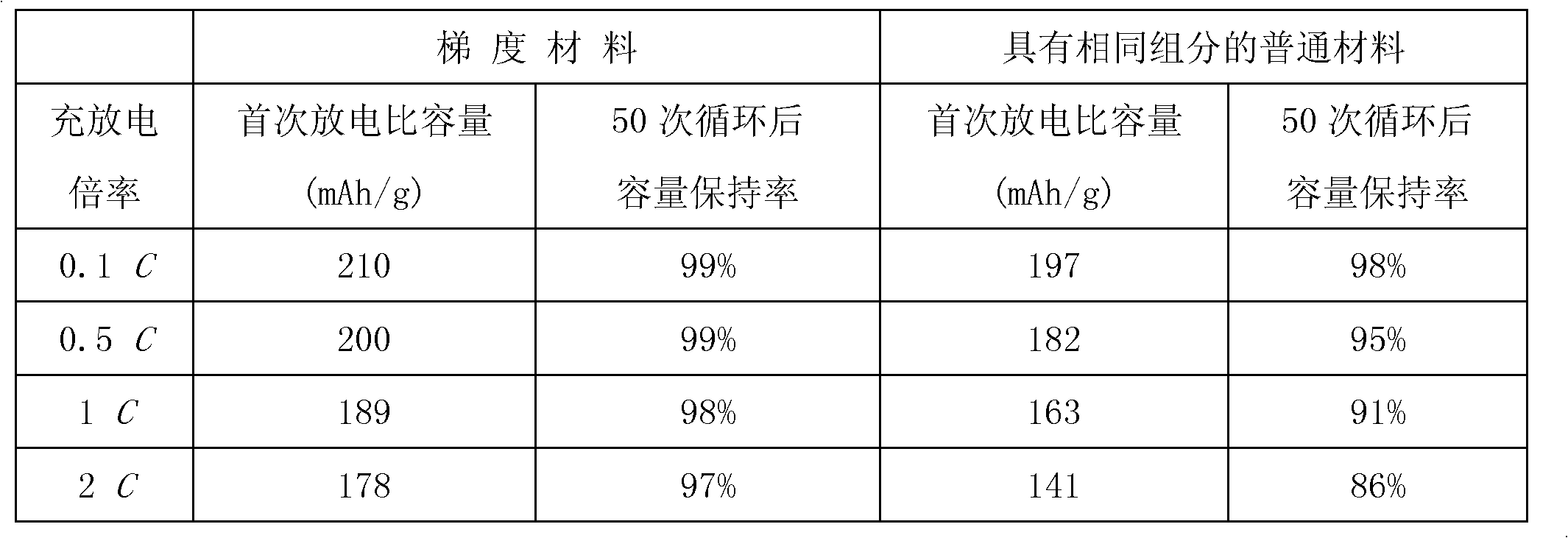

Examples

Embodiment 1

[0023] a. The precursor of the spherical high-nickel positive electrode material is dispersed into the solution system containing lithium nickel cobalt manganese: the acetate of lithium nickel manganese cobalt is used as the raw material, and the molar ratio of lithium nickel cobalt manganese element is 41.6:5:3:2 (wherein the molar ratio of the nickel element to the three elements of nickel, cobalt and manganese is 0.5), dissolved in deionized water; then the precursor Ni of the spherical high-nickel positive electrode material 0.8 co 0.1 Al 0.1 (OH) 2 (the mol ratio of the nickel-cobalt-manganese element total amount in the spherical high-nickel positive electrode material precursor and the nickel-cobalt-manganese element total amount in the solution is 3) and dispersant (dispersant is polyethylene glycol and alcohol, press positive electrode material quality 30%), and mixed uniformly in the prepared lithium-nickel-cobalt-manganese solution, stirred to form a suspension, a...

Embodiment 2

[0026] a. Disperse the precursor of the spherical high-nickel positive electrode material into a solution system containing lithium, nickel, cobalt, and manganese: the acetate of lithium, nickel, manganese, and cobalt is used as a raw material, and the molar ratio of lithium, nickel, cobalt, and manganese is 15.6:5:3:2 , dissolved in deionized water; and then weighed an appropriate amount of spherical high-nickel cathode material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 (the mol ratio of the nickel-cobalt-manganese element total amount in the spherical high-nickel cathode material precursor and the nickel-cobalt-manganese element total amount in the solution is 0.5) and citric acid (by 1% of the positive electrode material quality), and prepare in Mix evenly in lithium-nickel-cobalt-manganese solution, stir to form a suspension, and then spray dry the mixture at 200°C to obtain a precursor with a core-shell structure;

[0027] b. Preparation of a lithium ion positive electrode...

Embodiment 3

[0029] a. Disperse the precursor of the spherical high-nickel positive electrode material into the solution system containing lithium, nickel, cobalt, and manganese: the acetate of lithium, nickel, manganese, and cobalt is used as the raw material, and the molar ratio of lithium, nickel, cobalt, and manganese is 6.24:1:1:1 (wherein the molar ratio of nickel element in the three elements of nickel, cobalt and manganese is 1 / 3), dissolved in deionized water; then take an appropriate amount of spherical high-nickel cathode material precursor Ni 0.8 co0.1 mn 0.1 (OH) 2 (the mol ratio of the nickel-cobalt-manganese element total amount in the spherical high-nickel cathode material precursor and the nickel-cobalt-manganese element total amount in the solution is 1) and polyethylene glycol (by 10% of the positive electrode material quality), and in the preparation Mix evenly in a good lithium-nickel-cobalt-manganese solution, stir to form a suspension, and then spray-dry the mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com