Method for detecting surface defects of dustproof cover of bearing based on machine vision

A defect detection and machine vision technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as damage to corporate reputation, impact on the use of bearing machines, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with specific drawings and embodiments.

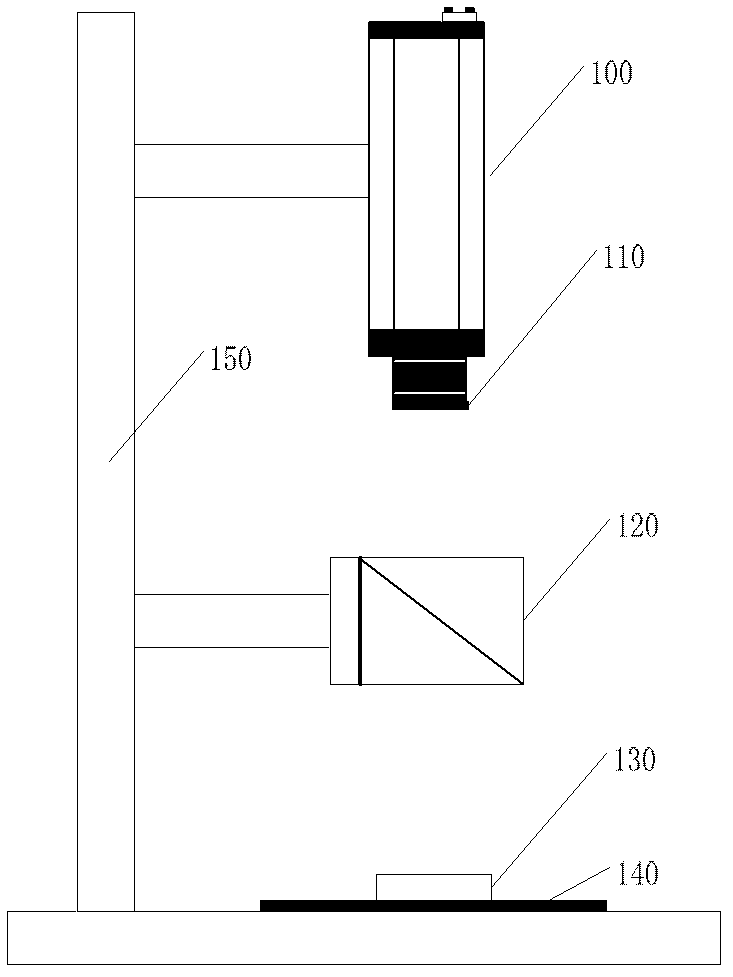

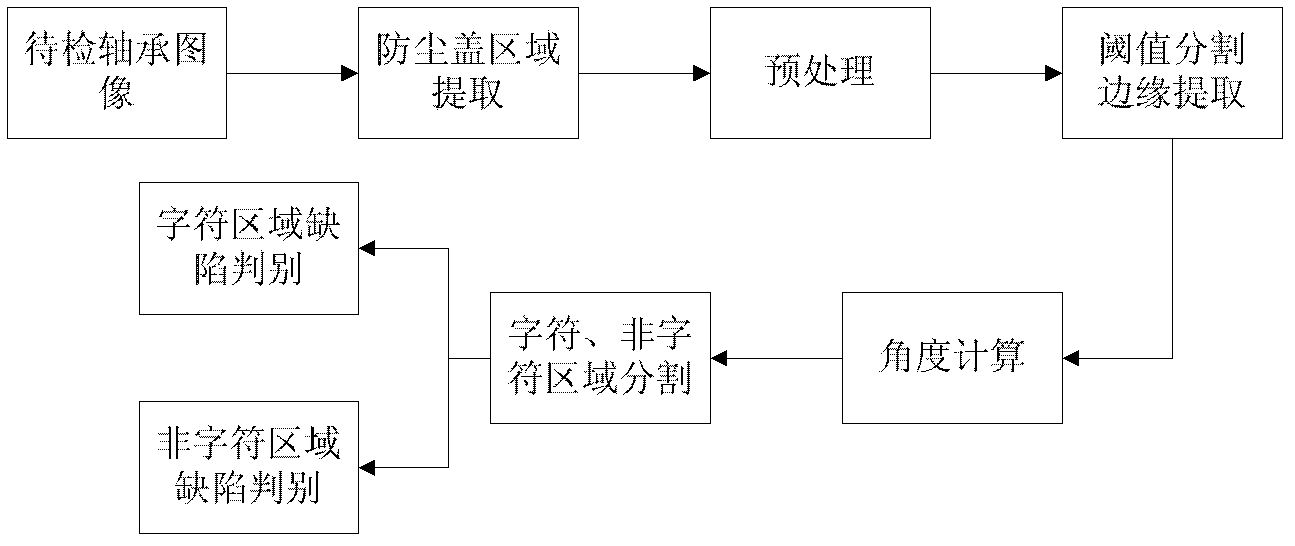

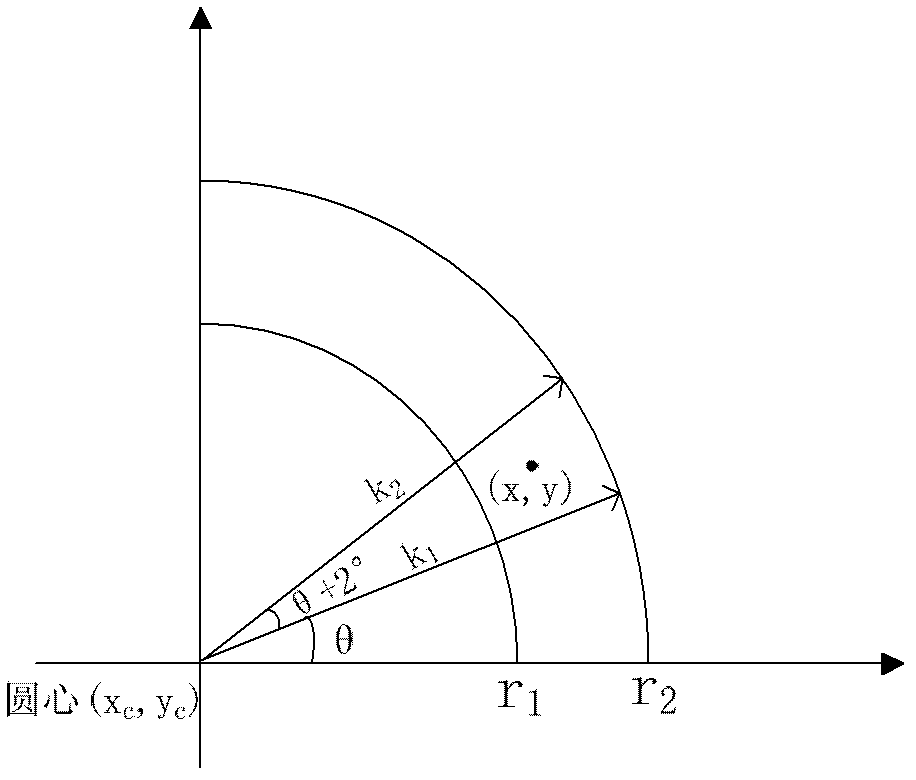

[0066] Such as figure 1 As shown: in order to obtain the image of the bearing dust cover conveniently, the present invention obtains the grayscale image of the bearing 130 to be tested first, and then obtains the ring image of the bearing dust cover after processing the grayscale image of the bearing 130 to be tested. When obtaining the image of the bearing 130 to be detected, the present invention includes a detection bracket 150, the detection bracket 150 has a base, and a support arm is provided directly above the base, and a CCD camera 100 and a blue coaxial The light source 120, the CCD camera 100 has a fixed-focus lens 110 corresponding to the end adjacent to the blue coaxial light source 120, and the axis of the CCD camera 100 and the axis of the blue coaxial light source 120 are located on the same straight line. When acquiring the grayscale image of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com