Composite coagulant for advanced treatment of biochemical tail water, as well as preparation method and application thereof

A technology of advanced treatment and coagulant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve the effect of dense floc, significant decolorization and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

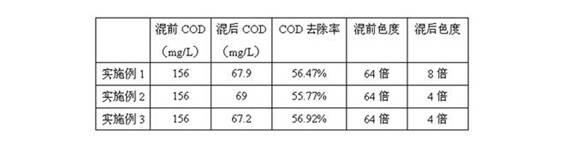

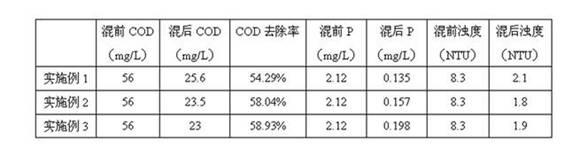

Examples

Embodiment 1

[0024] Example 1 of the present invention, using bentonite, scrap iron scraps, and boron mud to prepare a composite coagulant for advanced treatment of biochemical tail water containing boron polysilicon aluminum iron, the specific steps are as follows:

[0025] (1) Alkaline hydrolysis under heating: Mix and stir 4mol / L caustic soda solution and bentonite for reaction, the solution of caustic soda solution and bentonite will

[0026] The solid mass ratio was 3:1, the temperature was 150°C, and the reaction time was 4 hours. The supernatant was collected to adjust the pH value to 7, and the alkaline hydrolyzed substance was obtained after aging for 90 minutes.

[0027] (2) Acid leaching under heating: add pyrite slag, 5mol / L waste sulfuric acid and hydrogen peroxide to the residue of step 1, mix and stir the reaction, the liquid-solid quality of the waste sulfuric acid solution, the residue of step 1, and pyrite slag The ratio is 3:1, the temperature is 100°C, and the reaction ...

Embodiment 2

[0032] Example 2 of the present invention utilizes kaolin, waste iron scraps, and boron mud to prepare a composite coagulant for advanced treatment of biochemical tail water containing boron polysilicon aluminum iron, and the specific steps are as follows:

[0033] (1) Alkaline hydrolysis under heating: Mix and stir 6mol / L caustic soda solution and kaolin for reaction, the solution of caustic soda solution and kaolin

[0034] The solid mass ratio was 6:1, the temperature was 180°C, and the reaction time was 6 hours. The supernatant was collected to adjust the pH value to 6, and the alkaline hydrolyzed substance was obtained after aging for 180 minutes.

[0035](2) Acid leaching under heating: Add iron scraps, 6mol / L waste sulfuric acid and sodium hypochlorite to the residue in step 1, mix and stir for reaction, and the liquid-solid mass ratio of the waste sulfuric acid solution to the residue in step 1 and scrap iron scraps The ratio is 6:1, the temperature is 150°C, and the r...

Embodiment 3

[0039] Example 3 of the present invention utilizes gibbsite, pyrite slag, and boron mud to prepare a composite coagulant for advanced treatment of biochemical tail water containing boron polysilicon aluminum iron, and the specific steps are as follows:

[0040] (1) Alkaline hydrolysis under heating: Mix and stir 5mol / L caustic soda solution and gibbsite for reaction, the liquid-solid mass ratio of caustic soda solution and gibbsite is 5:1, the temperature is 200°C, and the reaction time is 8h. The supernatant was collected to adjust the pH value to 6, and the alkaline hydrolyzed substance was obtained after aging for 360 minutes.

[0041] (2) Acid leaching under heating: add pyrite slag, 5mol / L waste sulfuric acid and catalytic oxidant to the residue of step 1, mix and stir for reaction, the liquid-solid mixture of waste sulfuric acid solution and the residue of step 1, pyrite slag The mass ratio is 4:1, the temperature is 130°C, and the reaction time is 8 hours. The collected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com