A kind of composite iron salt coagulant and its preparation method and application

A technology of coagulant and iron salt, which is applied in the field of water treatment, can solve the problems of low removal rate of chemical oxygen demand, complex organic components, and many refractory substances, so as to achieve less dosage of chemicals, faster settling speed, and better preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) 100 tons of iron-containing waste hydrochloric acid (HCl%=4.51%, Fe 2 o 3 =11.91%) into the reaction kettle, add 400kg of sodium chlorate, stir and react at room temperature for 1 hour; (2) add 10 tons of aluminum-containing sludge (Al 2 o 3 =12.66%), continue stirring and reacting at normal temperature for 1 hour until the aluminum-containing sludge is completely dissolved; (3) add 1000kg of silicic acid dropwise and continue to react for 1 hour, filter to obtain a composite iron salt coagulant.

Embodiment 2

[0017] (1) 100 tons of iron-containing waste hydrochloric acid (HCl%=4.51%, Fe 2 o 3 =11.91%) into the reaction kettle, add 1200kg of sodium chlorate, stirred and reacted at room temperature for 2 hours; (2) add 20 tons of aluminum-containing sludge (Al 2 o 3 =12.66%), continue stirring and reacting at normal temperature for 2 hours to all dissolve the aluminum-containing sludge; (3) add 2500kg of silicic acid dropwise and continue to react for 1 hour, filter to obtain a composite iron salt coagulant.

Embodiment 3

[0019] (1) 100 tons of iron-containing waste hydrochloric acid (HCl%=4.51%, Fe 2 o 3 =11.91%) into the reaction kettle, add 2000kg of sodium chlorate, stir and react at room temperature for 1 hour; (2) add 30 tons of aluminum-containing sludge (Al 2 o 3 =12.66%), continue to stir and react at normal temperature for 2 hours to all dissolve the aluminum-containing sludge; (3) add 5000kg of silicic acid dropwise and continue to react for 2 hours, filter to obtain a composite iron salt coagulant.

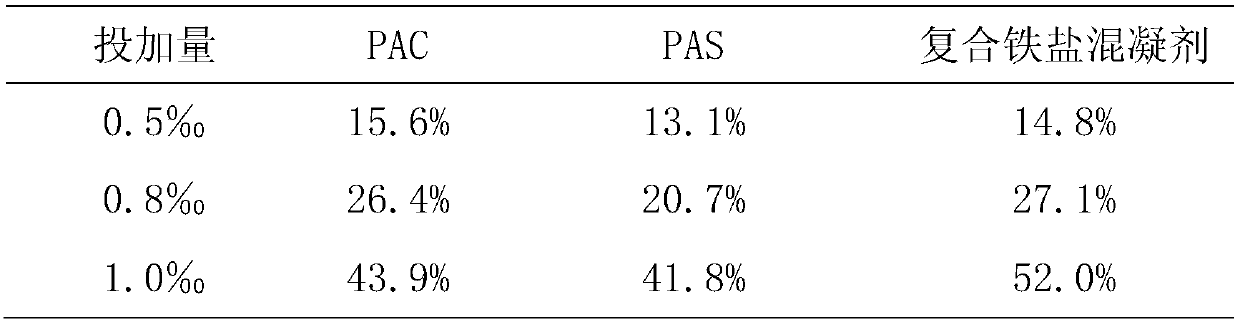

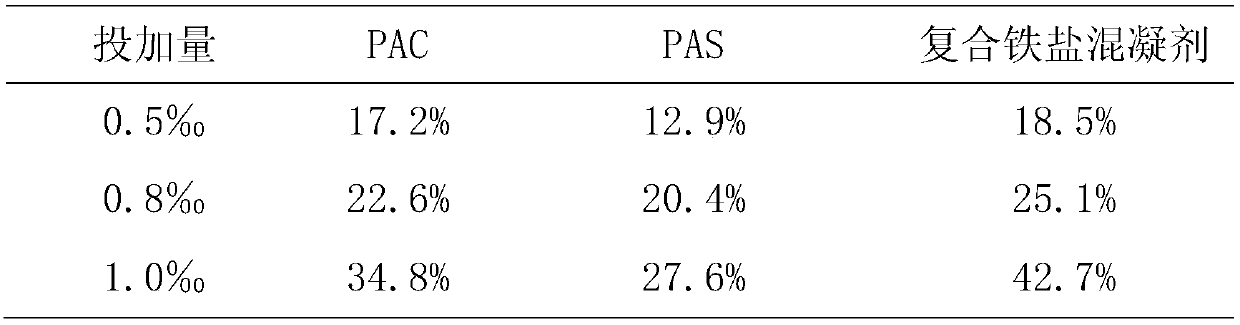

[0020] Composite coagulant effect evaluation that the present invention makes

[0021] The source of sewage is Wujiang Sanlian printing and dyeing front sewage, the appearance is light yellow and turbid, its COD is 683.1mg / L, and the turbidity is 189.3NTU. The same dosage of polyaluminum chloride (PAC) and polyaluminum sulfate (PAS) were used respectively Dilute it with the finished composite iron salt coagulant to 10% and add it into the sewage as a flocculant, and compare the COD a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com