Double-membrane-method technology for refining brine and equipment for the same

A technology of brine refining and double-membrane method, which is applied to the purification of alkali metal halides, etc., can solve the problems of secondary pollution, cumbersome pretreatment process, and increased risk of membrane fouling, so as to improve the impact load resistance and reduce the concentration difference Polarization phenomenon, the effect of prolonging the membrane cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

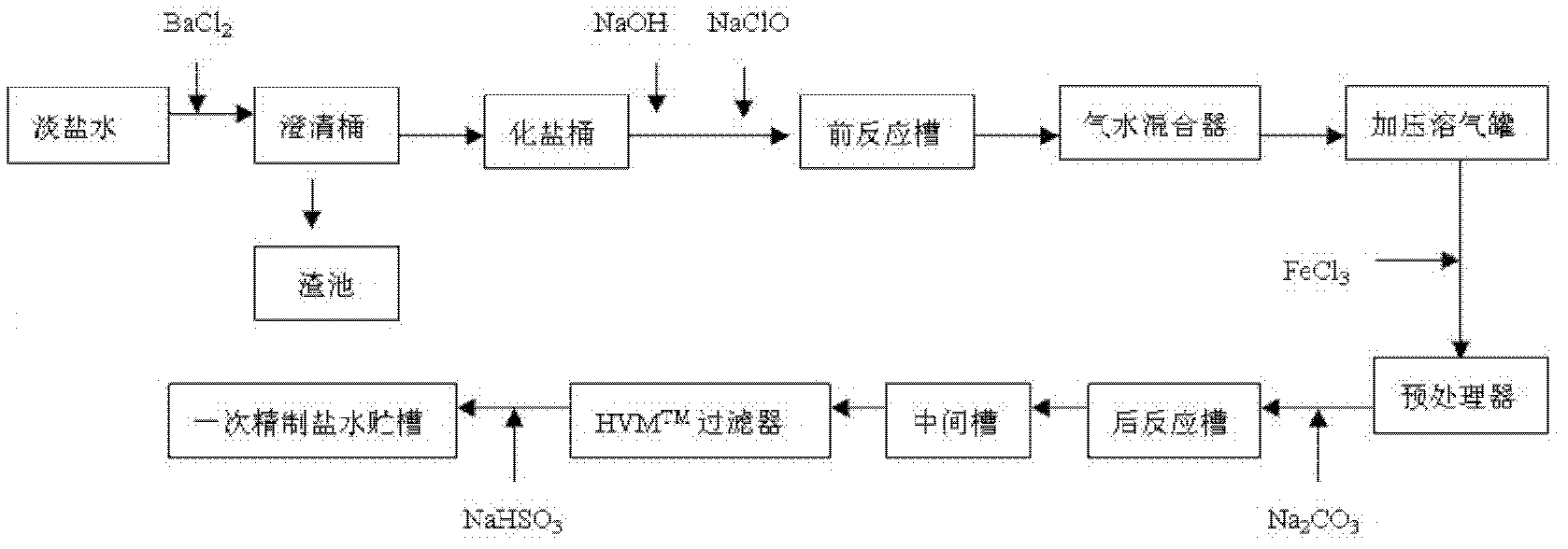

[0037] The original brine extracted from the mine is directly pumped into the reaction tank, after removing calcium and magnesium ions, it enters the ammonium removal program, and after adjusting the redox potential and pH value, the above brine is pumped into the stripping tube membrane module for ultrafiltration , so as to intercept the organic impurities, suspended matter and part of the sediment in the brine, the brine that passes through the tubular membrane directly enters the nanofiltration membrane module for nanofiltration, and the brine that does not pass through the tubular membrane returns to the calcium and magnesium removal program. The air-lift tube membrane permeated brine enters the nanofiltration membrane module after the pressure is raised by the high-pressure pump. Under high pressure, most of the sulfate ions are intercepted, and the chloride ions and sodi...

Embodiment 2

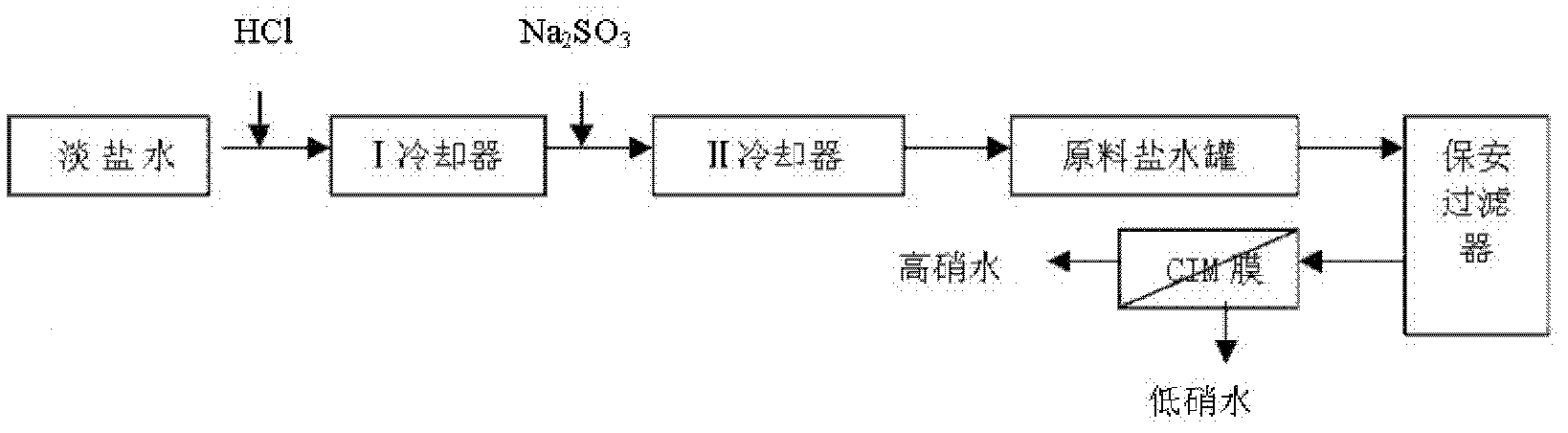

[0046] The calcium content in the raw halogen mined from the mine is 0.54g / L, the magnesium content is 0.07g / L, the sulfate content is 16.54g / L, and the suspended matter content is 1.89g / L. Pump the brine into the reaction barrel to remove calcium and magnesium ions, remove ammonium from the brine, remove free chlorine in the brine and adjust the pH of the brine to 7. After that, it enters the gas tubular membrane module for ultrafiltration through the pump, and the gas stripping tubular membrane permeates the brine after the pressure is raised by the high-pressure pump, and then enters the nanofiltration module, and finally obtains high-nitration water and refined brine.

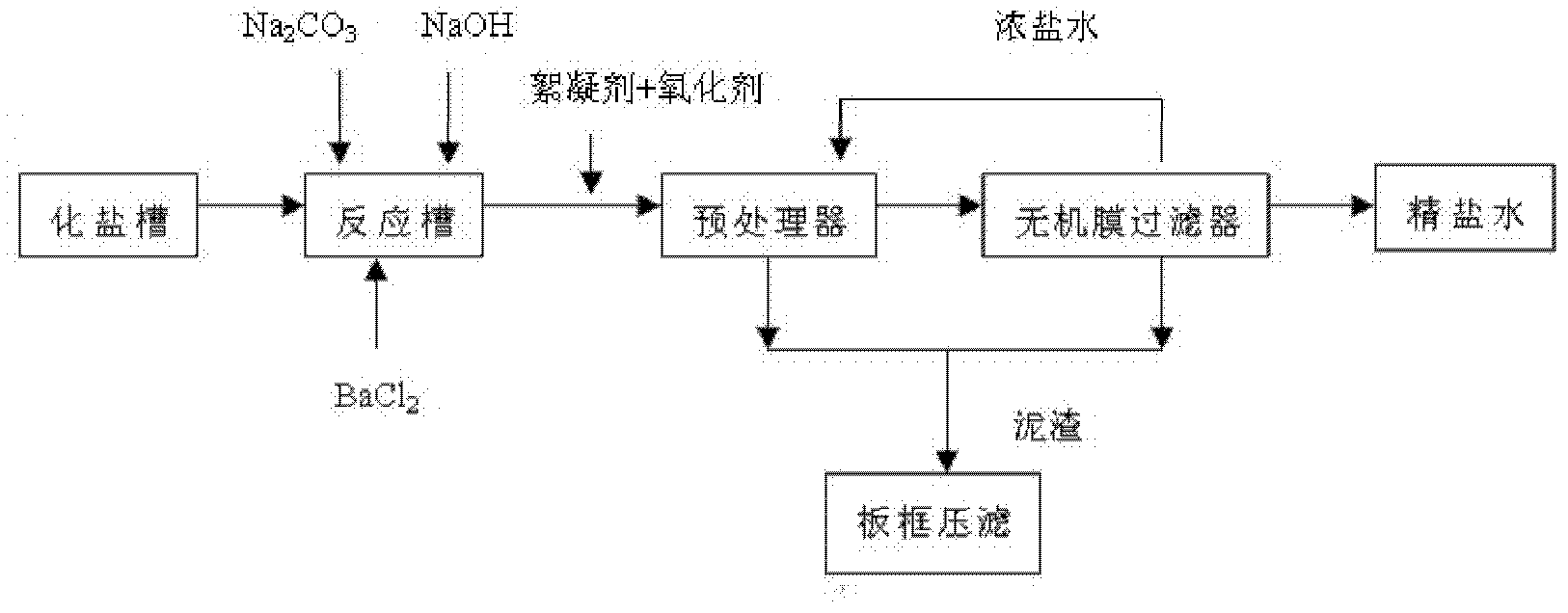

[0047] Add 1.68g / L of sodium carbonate and 0.32g / L of sodium hydroxide to the raw brine of the well mine for chemical reaction; after the reaction, add 50mg / L of polyferric chloride, stir well, and enter the plate frame after adsorption and co-precipitation Press filtration to remove calcium and magnesium i...

Embodiment 3

[0054] The calcium content in the raw halogen mined from the mine is 0.54g / L, the magnesium content is 0.07g / L, the sulfate content is 16.54g / L, and the suspended matter content is 1.89g / L. Pump the brine into the reaction barrel to remove calcium and magnesium ions, remove ammonium in the brine, remove free chlorine in the brine and adjust the pH of the brine to 7. The above-mentioned brine enters the gas tubular membrane module through the pump for ultrafiltration, and the air-lifting tubular membrane permeates the brine after the pressure is raised by the high-pressure pump, and then enters the multi-stage nanofiltration system, and finally obtains high-nitration water and refined brine

[0055] The steps to remove calcium and magnesium ions in brine are: add 1.68g / L sodium carbonate and 0.32g / L sodium hydroxide for reaction, add 50mg / L polyaluminium chloride after the reaction, stir well, and undergo adsorption and co-precipitation Then enter the plate and frame filter pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com