Method for improving power density of electric energy conversion device

A technology of electric energy conversion and power density, applied in circuits, electrical components, electrical digital data processing, etc., can solve problems such as inability to use voltage as much as possible, failure to reach thermal balance, temperature rise, etc., to reduce test workload , improve the power density, the effect of clear principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

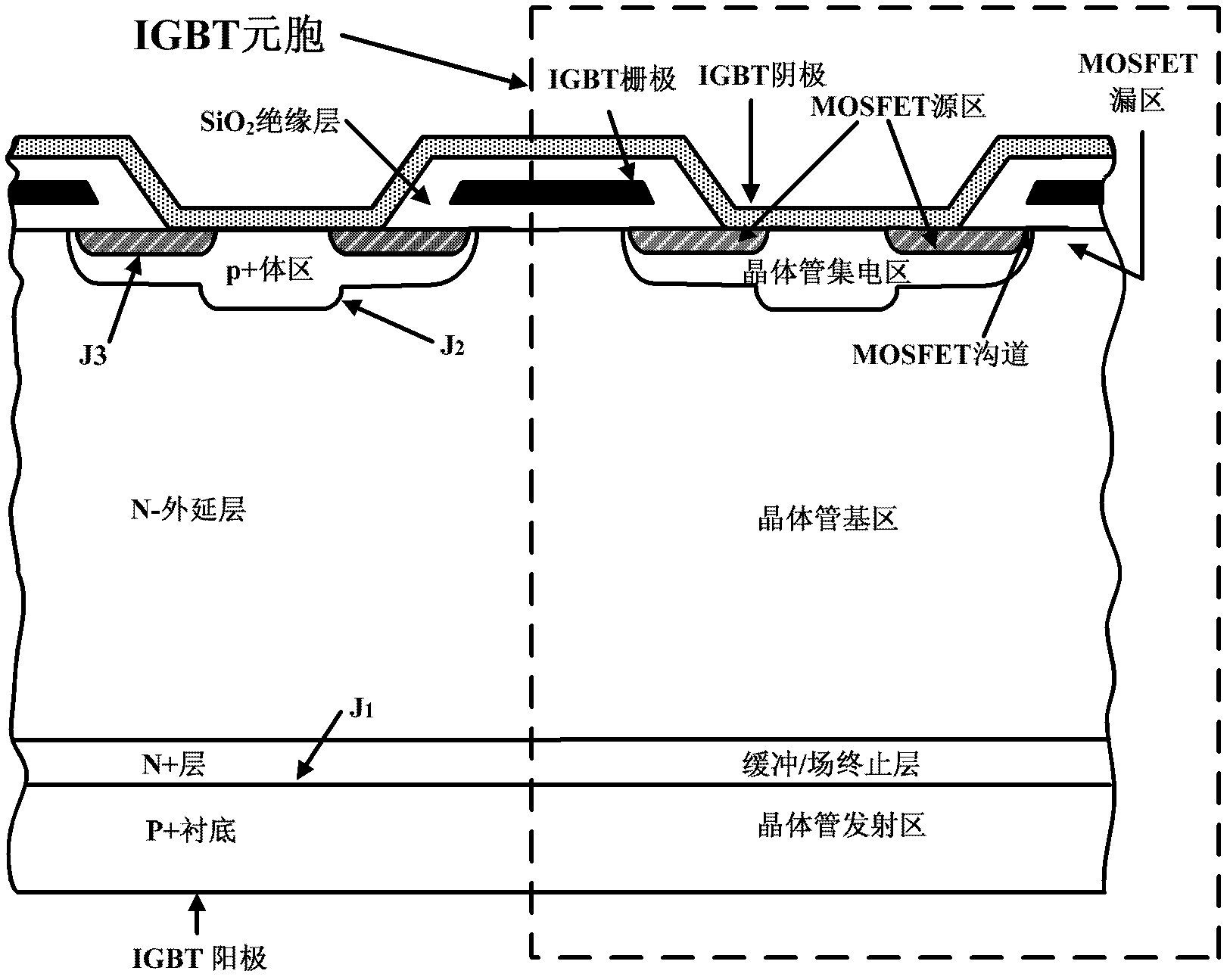

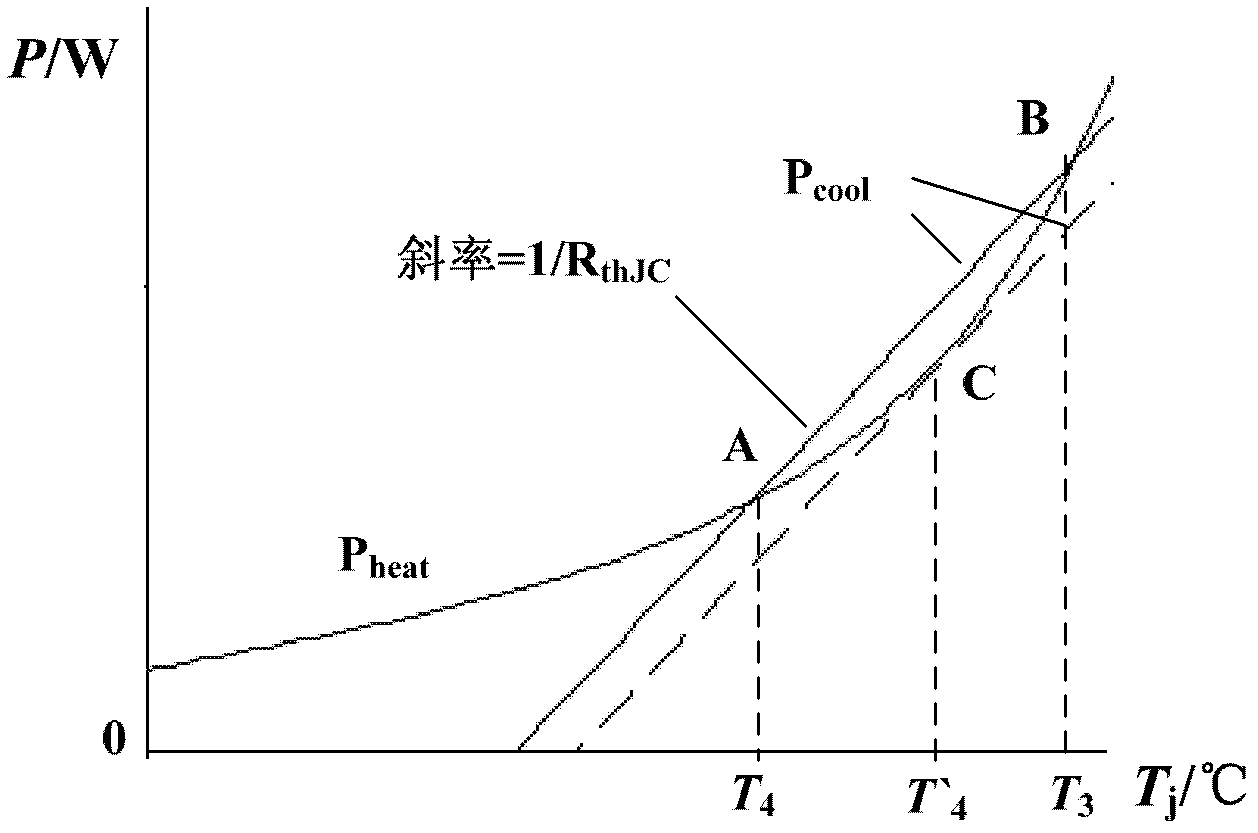

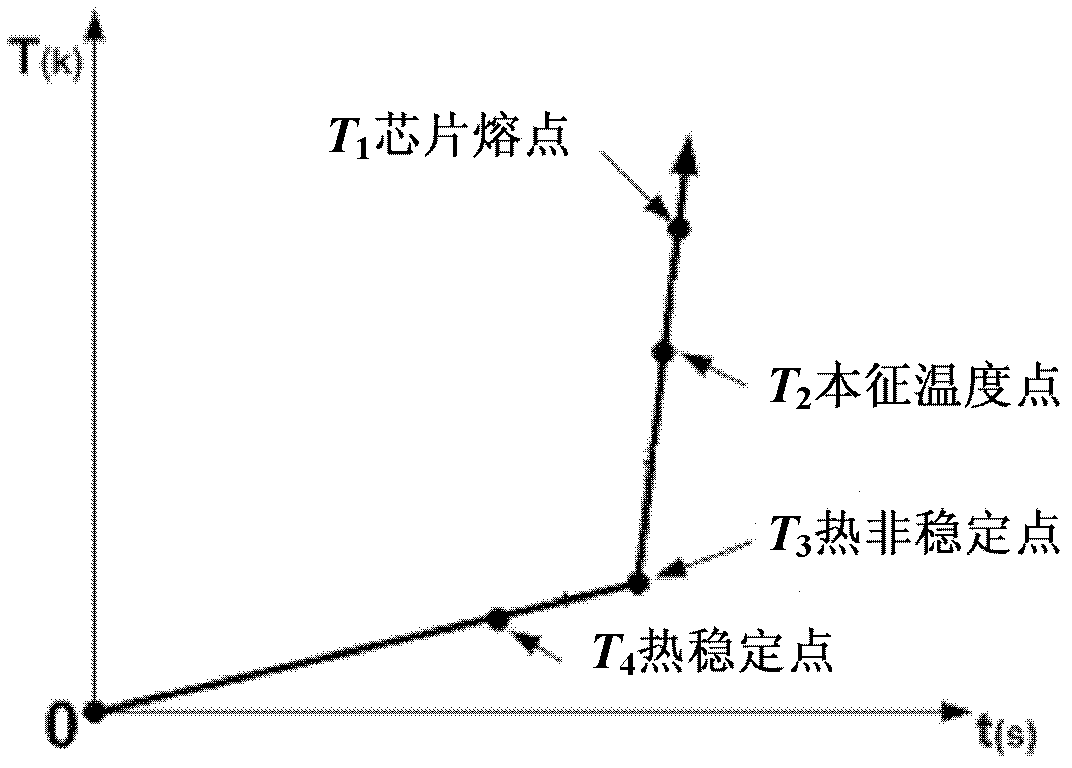

[0121] The analysis will be explained below in combination with specific examples. The IGBT device model is selected as GD50HFL120C1S. This device adopts the chip of ABB Company and is packaged in China. Its rated voltage and DC current are 1200V and 50A respectively. It is a soft pass-through two-unit half-bridge module. A chopper circuit with diode freewheeling is used, and the circuit conditions are set as follows: voltage 600V, duty cycle 0.5, case temperature 80°C, and it is required to design the limit of switching frequency under different current conditions. The design steps are:

[0122] (1) Since this type of device belongs to the PT type, the PT type model is adopted. From the conduction steady state, switching transient and off-state mathematical models, the expressions of conduction voltage drop, switching voltage, switching current and collector leakage current are obtained, and the conduction power consumption, switching power consumption and The off-state pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com