Method for preparing foaming material by adopting bamboo liquefied product

A technology for liquefied products and foaming materials, which is applied in the field of preparing foaming materials to achieve the effects of protecting the ecological environment, stable quality and uniform pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The inventor has applied for a Chinese patent (application number 201110440838.9) for the preparation method of the bamboo liquefaction product resin.

[0026] The bamboo phenolic alcohol liquefaction product adopted in the above method is made from bamboo waste and processing residues; the specific method is:

[0027] 1) first crush small-diameter bamboo or / and bamboo processing residues to 20-80 mesh, and dry until the moisture content is less than 10% for later use;

[0028] 2) add the bamboo powder of 100 mass parts, the phenol of 50-75 mass parts, the polyethylene glycol of 50-75 mass parts and the acid catalyst of 15-30 mass parts in reaction vessel, normal pressure reaction 30-90min, reaction The temperature is 110°C-170°C; after the reaction is completed, the temperature is lowered to room temperature, and 15-30 parts by mass of caustic soda solution is added for neutralization to obtain a bamboo phenolic alcohol liquefaction product.

[0029] The acid catalyst...

Embodiment

[0034] 1.1 Materials

[0035] Bamboo liquefied resin: 100 parts by mass, self-made;

[0036] Surfactant: OP-10 emulsifier and Tween 80 with a mass ratio of 1:1; 5-15 parts by mass.

[0037] Filler: calcium carbonate, 8-12 parts by mass.

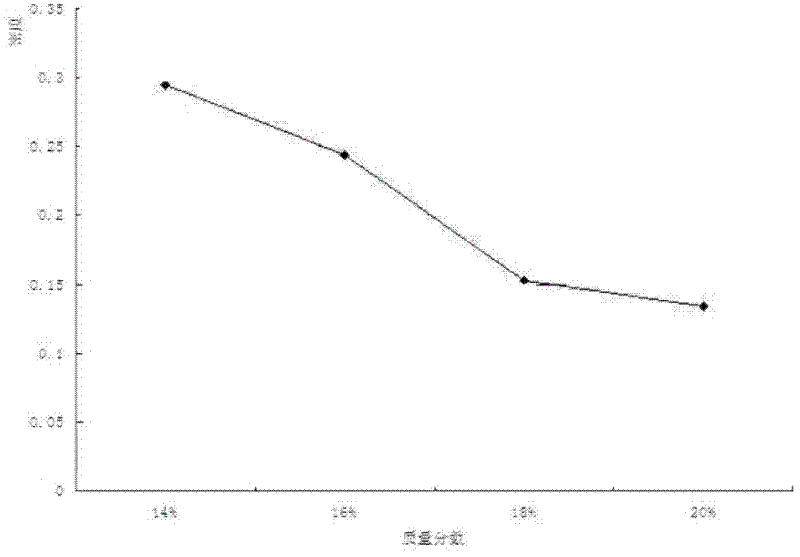

[0038] Curing agent: (one or two of p-toluenesulfonic acid and phosphoric acid mixed in any proportion), the mass parts are 16-20.

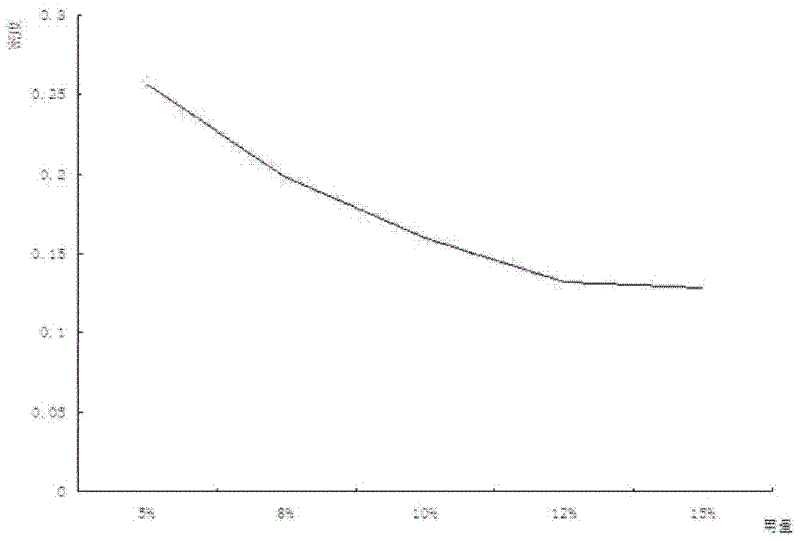

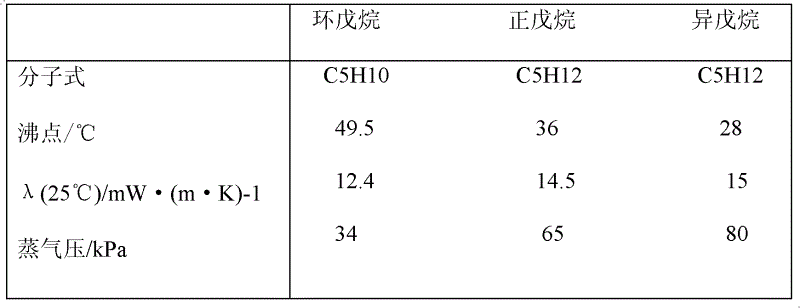

[0039] Foaming agent; a mixture of one or more of n-pentane, isopentane and cyclopentane in any proportion, with 8-15 parts by mass.

[0040] Isocyanate; parts by mass are 30-50.

[0041] Except the bamboo liquefied resin, all other materials in the present invention are purchased externally.

[0042] 1.2 Main equipment

[0043] automatic stirrer; mould; electronic balance; blast drying oven; glass rod

[0044] 1.3 Method

[0045] 1.3.1 Preparation of foaming material: first add surfactant, filler and foaming agent to the resin, stir well, then add curing agent and isocyanate, stir quickly for 15-25s, pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com