Fluorine monomer modified styrene-acrylic emulsion and preparation method thereof

A technology of styrene-acrylic emulsion and fluorine monomer, which is applied in the direction of coating, etc., can solve the problems of easy flocculation, poor stability of emulsion polymerization, and limitation of waterproof performance of silicone-modified acrylic emulsion film, and achieve great market development potential , Excellent acid resistance, good low temperature flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

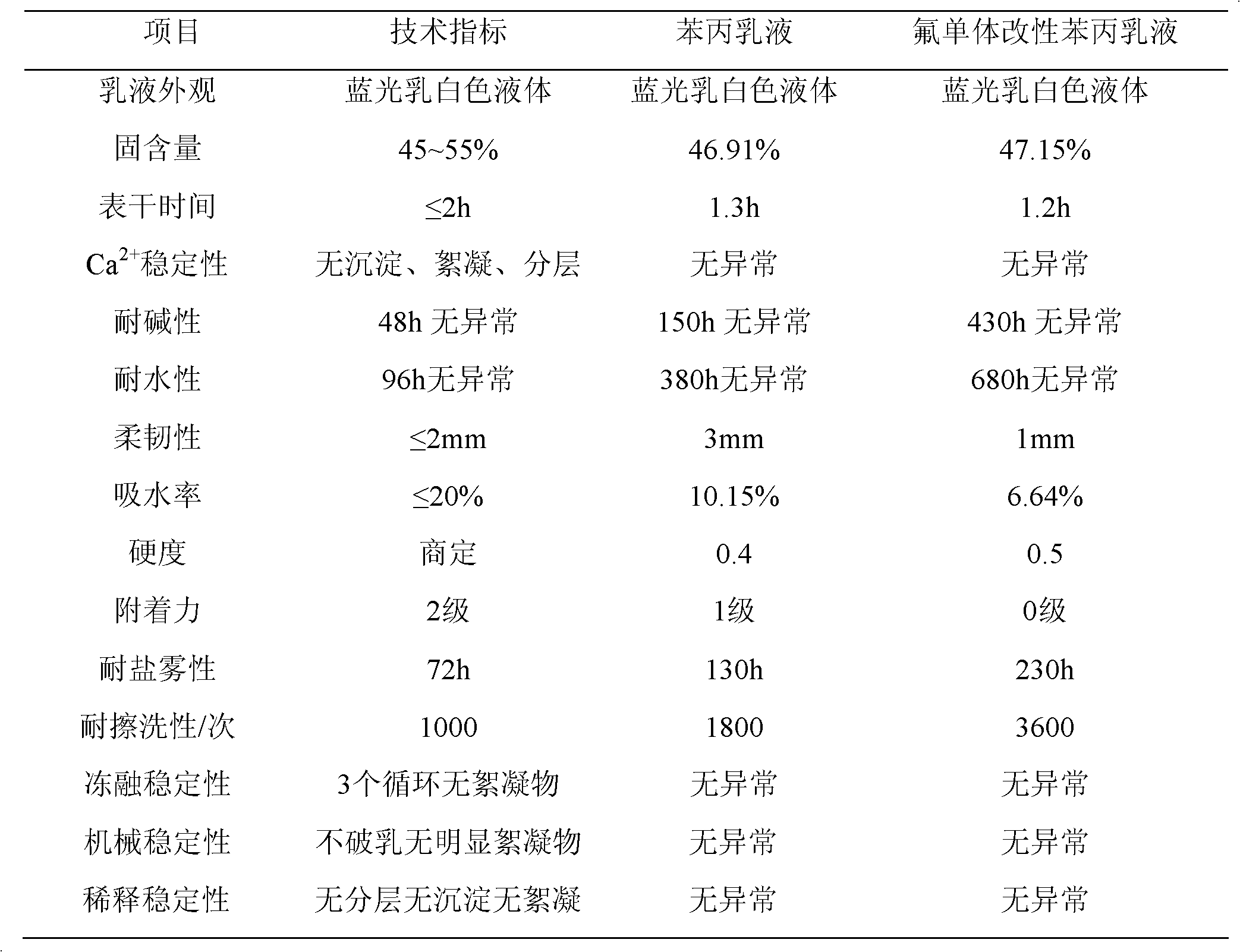

Examples

Embodiment 1

[0026] A kind of fluoromonomer modified styrene-acrylic emulsion, it is made up of the component of following mass percentage:

[0027] Fluoroalkyl Methacrylate 1.0%,

[0028] Methyl Methacrylate 5.0%,

[0029] Sodium dodecylbenzenesulfonate 0.5%,

[0030] Fatty alcohol polyoxyethylene ester 0.5%,

[0031] Styrene 20%,

[0032] Butyl Acrylate 25%,

[0033] Alkylphenol ethoxylates 1.0%,

[0034] Sodium bicarbonate 0.1%,

[0035] Potassium persulfate 0.4%,

[0036] Ammonia 0.5%,

[0037] The rest is water.

[0038] The preparation method is as follows:

[0039] (1) Mix 4 / 5 of the formula amount of water with the formula amount of methyl methacrylate, sodium dodecylbenzenesulfonate, fatty alcohol polyoxyethylene ester, styrene, butyl acrylate, alkylphenol polyoxyethylene Mix ether with strong stirring to emulsify into pre-emulsion;

[0040] (2) Potassium persulfate and sodium bicarbonate of formula quantity are dissolved in the water of remaining 1 / 5 formula quantity t...

Embodiment 2

[0047] A kind of fluoromonomer modified styrene-acrylic emulsion, it is made up of the component of following mass percentage:

[0048] Fluoroalkyl Methacrylate 2.0%,

[0049] Methyl Methacrylate 6.0%,

[0050] Sodium dodecylbenzenesulfonate 0.2%,

[0051] Fatty alcohol polyoxyethylene ester 0.3%,

[0052] Styrene 21%,

[0053] Butyl Acrylate 22%,

[0054] Alkylphenol Ethoxylates 3.0%,

[0055] Sodium bicarbonate 0.3%,

[0056] Potassium persulfate 1.0%,

[0057] Ammonia 0.2%,

[0058] The rest is water.

[0059] The preparation method is as follows:

[0060] (1) Mix 4 / 5 of the formula amount of water with the formula amount of methyl methacrylate, sodium dodecylbenzenesulfonate, fatty alcohol polyoxyethylene ester, styrene, butyl acrylate, alkylphenol polyoxyethylene Mix ether with strong stirring to emulsify into pre-emulsion;

[0061] (2) Potassium persulfate and sodium bicarbonate of formula quantity are dissolved in the water of remaining 1 / 5 formula quantity t...

Embodiment 3

[0067]A kind of fluoromonomer modified styrene-acrylic emulsion, it is made up of the component of following mass percentage:

[0068] Fluoroalkyl Methacrylate 4.0%,

[0069] Methyl Methacrylate 7.0%,

[0070] Sodium dodecylbenzenesulfonate 0.8%,

[0071] Fatty alcohol polyoxyethylene ester 0.2%,

[0072] Styrene 22%,

[0073] Butyl Acrylate 23%,

[0074] Alkylphenol ethoxylates 2.0%,

[0075] Sodium bicarbonate 0.5%,

[0076] Potassium persulfate 0.7%,

[0077] Ammonia 0.8%,

[0078] The rest is water.

[0079] The preparation method is as follows:

[0080] (1) Mix 4 / 5 of the formula amount of water with the formula amount of methyl methacrylate, sodium dodecylbenzenesulfonate, fatty alcohol polyoxyethylene ester, styrene, butyl acrylate, alkylphenol polyoxyethylene Mix ether with strong stirring to emulsify into pre-emulsion;

[0081] (2) Potassium persulfate and sodium bicarbonate of formula quantity are dissolved in the water of remaining 1 / 5 formula quantity to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com