Method for simultaneously preparing total caffeoylquinic acid and stevioside by taking stevia as raw material

A technology of caffeoylquinic acid and stevioside, applied in chemical instruments and methods, preparation of carboxylic acid esters, preparation of sugar derivatives, etc., can solve problems such as environmental pollution and resource waste, reduce environmental pollution and improve comprehensive benefits , the effect of shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Example 1: Take 1 kg of stevia leaf powder, add 20 L of water or deionized water, adjust the pH to 3.0, and boil for 5 minutes to extract. Filter and concentrate after extraction. The concentrated solution was extracted with ethyl acetate; the ethyl acetate extract in the upper layer was concentrated, then adsorbed with NKA-9 macroporous resin column, and eluted with deionized water and ethanol with a volume concentration of 60% in sequence to collect the total coffee containing The eluate of dicaffeoylquinic acid in acylquinic acid was concentrated and dried to obtain 15.90 g of dicaffeoylquinic acid with a content of 80.0%. The extracted extract in the lower layer is adsorbed on the AB-8 macroporous resin column, eluted with deionized water and ethanol solution in turn, and the eluate containing monocaffeoylquinic acid and stevioside is collected, concentrated and dried to obtain the content 3.78g of 78.56% monocaffeoylquinic acid; after the eluate of stevioside is c...

example 2

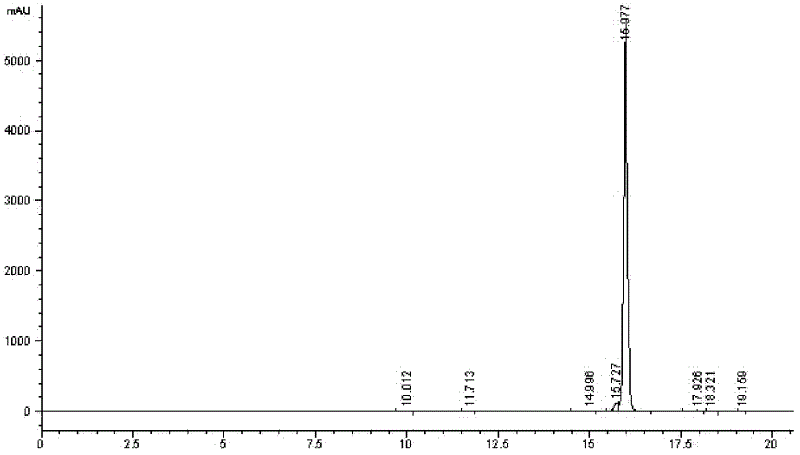

[0036] Example 2: Take 1 kg of Stevia rebaudiana leaf powder, add 40 L of 70% ethanol solution, adjust the pH to 3.5, and perform ultrasonic extraction. Filter and concentrate after extraction. The concentrated solution was extracted with ethyl acetate; the ethyl acetate extract in the previous step was concentrated, then adsorbed with HPD500 macroporous resin column, eluted with deionized water and ethanol with a volume concentration of 70% in sequence, and collected the dicaffeoylquinone containing The eluate of nicotinic acid was concentrated and dried to obtain 17.40 g of dicaffeoylquinic acid with a content of 92.45%. The extracted extract was adsorbed on HPD450 macroporous resin column, eluted with deionized water and ethanol solution successively, and the eluate containing monocaffeoyl quinic acid was collected, concentrated and dried to obtain monocaffeoyl quinic acid with a content of 90.32%. Quinic acid 4.72g. After the eluate of stevioside is concentrated, calcium...

example 3

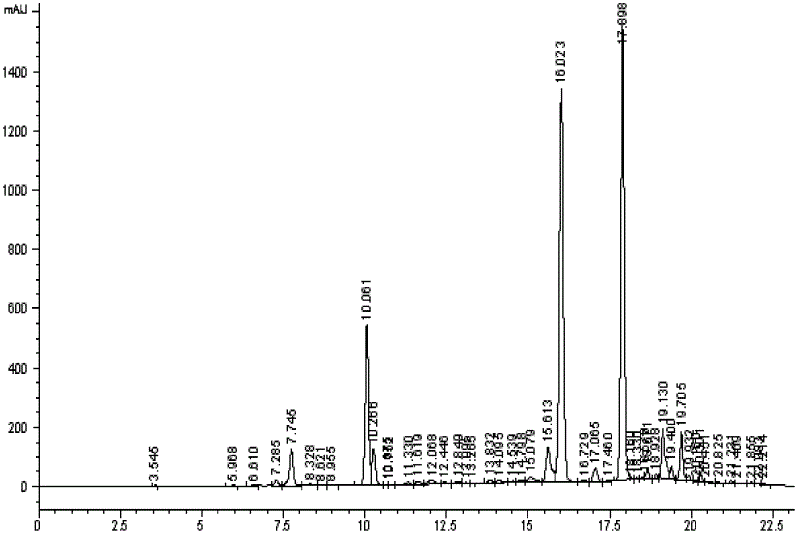

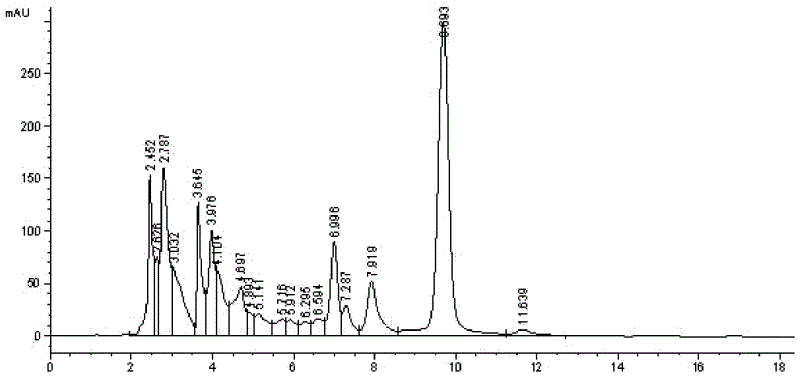

[0037] Example 3: Get the stevia leaf powder of 1kg, add 80L of 50% methanol solution, adjust the pH to 4.0, ultrasonic extraction (see the total caffeoylquinic acid content in the extract figure 1 , for total stevia content see figure 2 ). Filter and concentrate after extraction. The concentrated solution was extracted with ethyl acetate; the ethyl acetate extract in the previous step was concentrated, then adsorbed with NKA-II macroporous resin column, eluted with deionized water and ethanol with a volume concentration of 50% in sequence, and collected the The eluate of acylquinic acid was concentrated and dried to obtain 16.85 g of dicaffeoylquinic acid with a content of 81.50%. The extracted extract was adsorbed on a D201 macroporous resin column, eluted with deionized water and ethanol solution in turn, and the eluate containing monocaffeoyl quinic acid was collected, concentrated and dried to obtain monocaffeoyl quinic acid with a content of 83.12%. 4.56g of quinic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com