Method for ultrasound-assisted extraction of lappaconitine

A technology of ultrasonic-assisted extraction and high urine, applied in the direction of organic chemistry, can solve the problems of cumbersome process, high cost, cumbersome operation process, etc., and achieve the effect of easy industrialization, short production cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

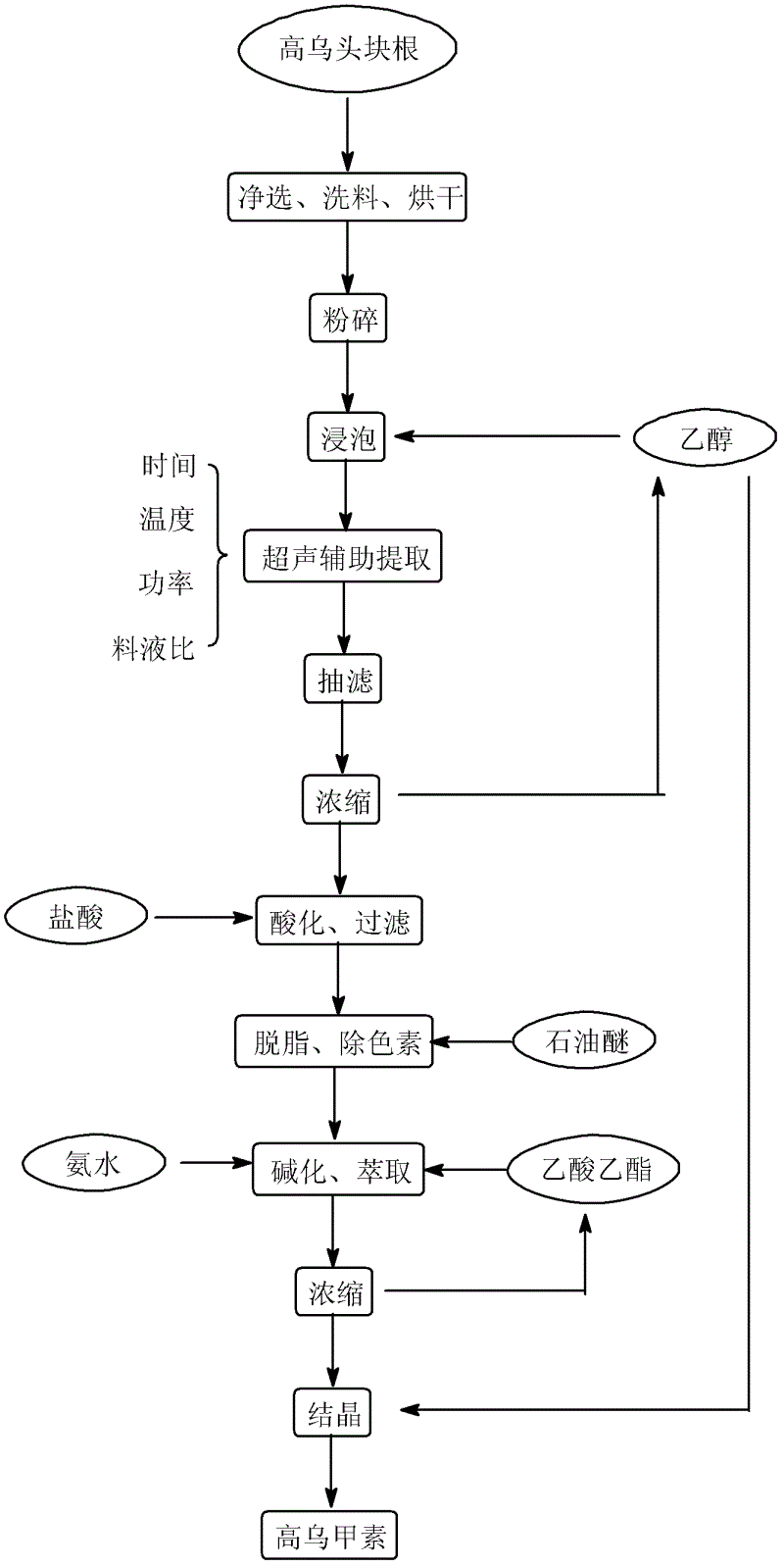

[0042] A kind of method of ultrasound-assisted extraction of homogenate of the present invention, comprises the following steps:

[0043] 1) Medicinal material pretreatment

[0044] Pulverize the roots of Aconitum aconitum and pass through a 60-mesh sieve to obtain medicinal powder of Aconitum aconitum;

[0045] 2) Ultrasonic extraction

[0046] The high aconitum medicinal powder and the ethanol that the volume fraction is 95% are soaked for 12 hours according to the mass volume ratio of 1g: 10mL, using an ultrasonic cleaner (KQ-250DE type numerical control ultrasonic cleaner, Kunshan Ultrasonic Instrument Co., Ltd.), at a power of 150W , under the condition of a temperature of 40° C., ultrasonic extraction for 30 minutes; suction filtration under the condition of a vacuum of 0.07 MPa, repeating step 2) for the obtained filter residue to extract once more, and combining the two filtrates for suction filtration to obtain the filtrate;

[0047] 3) Preparation of acid water

[0...

Embodiment 2

[0054] A kind of method of ultrasound-assisted extraction of homogenate of the present invention, comprises the following steps:

[0055] 1) Medicinal material pretreatment

[0056] Pulverize the roots of Aconitum aconitum and pass through an 80-mesh sieve to obtain medicinal powder of Aconitum aconitum;

[0057] 2) Ultrasonic extraction

[0058] The high aconitum medicinal powder and the ethanol whose volume fraction is 95% are soaked for 36 hours according to the mass volume ratio of 1g: 20mL, using an ultrasonic cleaner (KQ-250DE type numerical control ultrasonic cleaner, Kunshan Ultrasonic Instrument Co., Ltd.), at a power of 250W , under the condition of a temperature of 60° C., ultrasonic extraction for 40 minutes; suction filtration under the condition of a vacuum of 0.08 MPa, repeat step 2) of the obtained filter residue to extract once more, and combine the filtrates twice to obtain the filtrate;

[0059] 3) Preparation of acid water

[0060] The filtrate obtained ...

Embodiment 3

[0069] A kind of method of ultrasound-assisted extraction of homogenate of the present invention, comprises the following steps:

[0070] 1) Medicinal material pretreatment

[0071] Pulverize the roots of Aconitum aconitum and pass through a 60-mesh sieve to obtain medicinal powder of Aconitum aconitum;

[0072] 2) Ultrasonic extraction

[0073] The high aconitum medicament powder and the ethanol that the volume fraction is 95% are soaked 24 hours according to mass volume ratio 1g: 15mL, use ultrasonic cleaner (KQ-250DE type digital control ultrasonic cleaner, Kunshan Ultrasonic Instrument Co., Ltd.), in power 200W , under the condition of a temperature of 50° C., ultrasonic extraction for 50 minutes; suction filtration under the condition of a vacuum of 0.09 MPa, repeat step 2) for the obtained filter residue to extract once more, and combine the filtrates twice to obtain the filtrate;

[0074] 3) Preparation of acid water

[0075] The filtrate obtained in step 2) was conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com