Persimmon tannin-containing metal adsorbent and preparation method thereof

An adsorbent and metal technology, which is applied in the field of natural product preparation, can solve the problems of severe reaction conditions, dimethylamine harmful to the environment, and easy volatility, and achieve the effects of low extraction cost, abundant resources, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

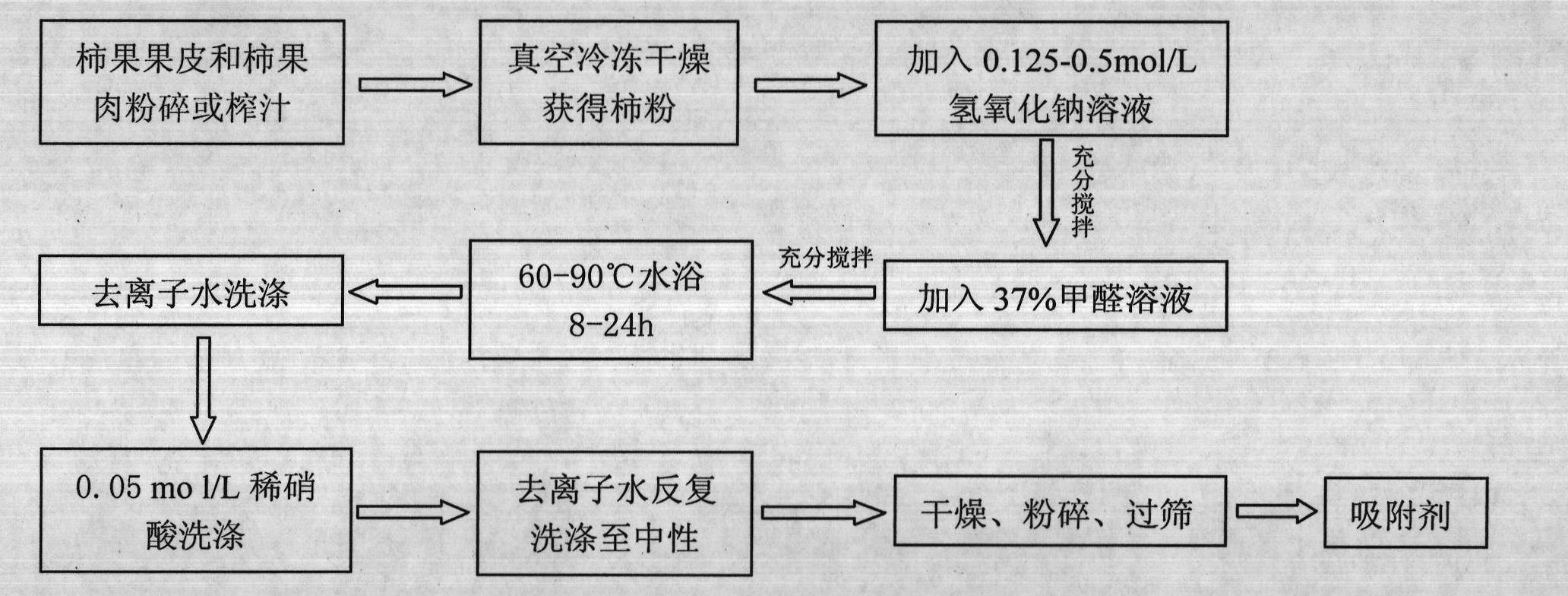

[0024] Example 1 Preparation Example

[0025] (1) Wash the raw persimmon fruit or persimmon skin containing persimmon tannins, crush or squeeze the juice, freeze-dry under vacuum at 40-200Mpa for 10-40h to obtain persimmon tannin-containing persimmon powder, or place it at -4°C Refrigerate, reserve;

[0026] (2) Take 30 g of freeze-dried persimmon powder, add 65 mL of 0.25 mol / L sodium hydroxide solution, and stir thoroughly;

[0027] (3) After adding 6mL of 37% (v / v) formaldehyde solution and fully stirring, the obtained solid granular adsorbent;

[0028] (4) Put the above-mentioned adsorbent in a water bath at 80° C. for 12 hours to make the reaction fully;

[0029] (5) Wash the fully reacted adsorbent once with deionized water, then wash once with 100mL 0.05mol / L dilute nitric acid solution, and finally wash with deionized water repeatedly until neutral and remove soluble substances therein;

[0030] (6) fully drying the obtained adsorbent after washing at 60-70° C. so t...

Embodiment 2

[0032] Embodiment 2 preparation embodiment

[0033] (1) Wash the raw persimmon fruit or persimmon skin containing persimmon tannins, crush or squeeze the juice, freeze-dry under vacuum at 40-200Mpa for 10-40h to obtain persimmon tannin-containing persimmon powder, or place it at -4°C Refrigerate, reserve;

[0034] (2) Put 600 g of freeze-dried persimmon powder into 1300 mL of 0.25 mol / L sodium hydroxide solution, and stir thoroughly;

[0035] (3) After adding 120mL of 37% (v / v) formaldehyde solution and fully stirring, a solid granular adsorbent can be obtained;

[0036] (4) Put the above-mentioned adsorbent in a water bath at 80° C. for 24 hours to make the reaction fully;

[0037] (5) Wash the fully reacted adsorbent with deionized water once, then wash once with 2000mL 0.05mol / L dilute nitric acid solution, and finally wash with deionized water repeatedly until neutral and remove soluble substances;

[0038] (6) drying the adsorbent after washing at 60-70°C so that its w...

Embodiment 3

[0040] Embodiment 3 preparation embodiment

[0041] (1) Wash the raw persimmon fruit or persimmon skin containing persimmon tannins, crush or squeeze the juice, freeze-dry under vacuum at 40-200Mpa for 10-40h to obtain persimmon tannin-containing persimmon powder, or place it at -4°C Refrigerate, reserve;

[0042] (2) Add 40g of persimmon powder into 80mL of 0.25mol / L sodium hydroxide solution, and stir well;

[0043] (3) Add 4mL of 37% (v / v) formaldehyde solution and stir well;

[0044] (4) Put the above mixture into a water bath at 80°C for 12 hours to make it fully react;

[0045] (5) Wash the fully reacted product once with deionized water, then wash once with 100mL of 0.05mol / L dilute nitric acid, and finally wash it with deionized water repeatedly to neutrality and remove soluble substances;

[0046] (6) Put the washed product into a 60-70°C oven to fully dry it so that its water content is less than 5%; and

[0047] (7) Pulverize the dried product and pass through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com