Wafer-level vacuum encapsulated infrared focal plane array (IRFPA) device and method for producing same

A vacuum packaging, wafer-level technology, used in electrical radiation detectors, radiation control devices, etc., can solve the problems of reducing imaging quality, manufacturing, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

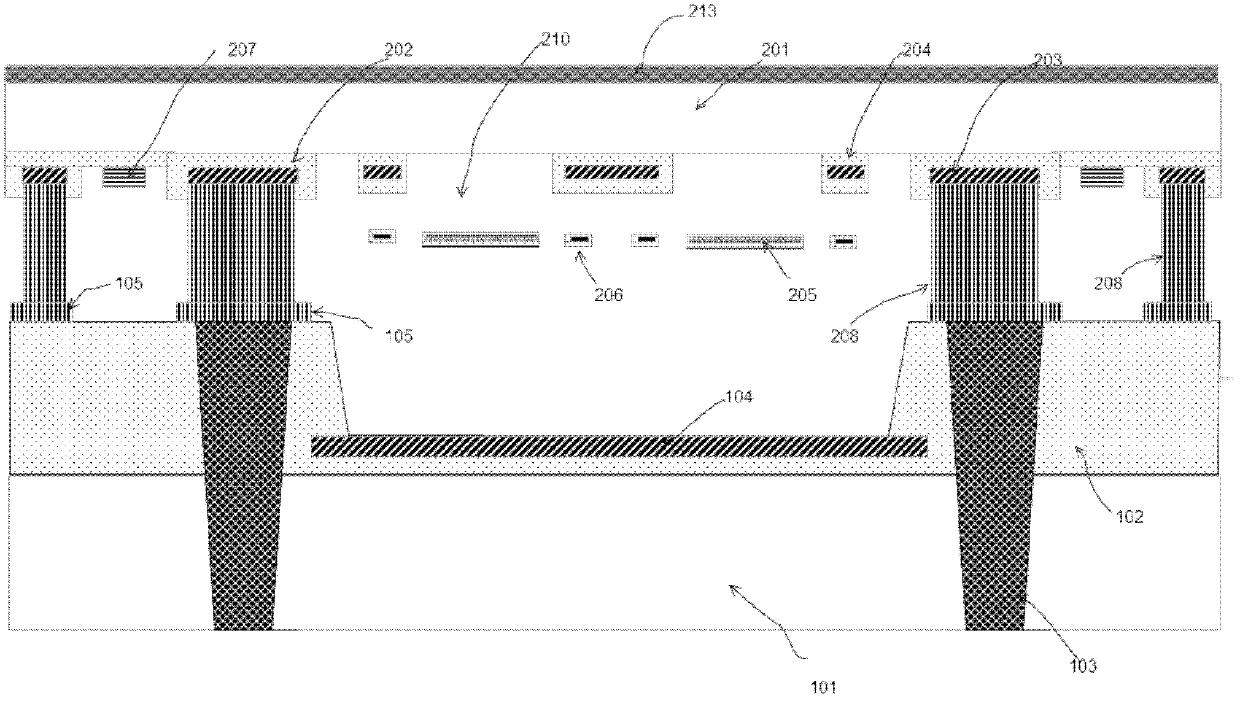

[0067] The structural sectional view of embodiment 1 of the present invention is as figure 2As shown, the first wafer 101 and the second wafer 201 are included. On the silicon substrate of the second wafer 201, the infrared focal plane array device is manufactured by photolithography and etching of the conventional IC process. microstructure. The specific structure is: the first wafer 101 is a conventional silicon wafer, and the readout circuit of the IR FPA is produced by using a conventional IC manufacturing process, and at the same time, the uppermost layer metal of the first wafer 101 is used to produce the IR FPA device. The resonant absorbing reflector 104; on the side of the first wafer 101 with the reflector 104, a dielectric material 102 is deposited, and a TSV structure 103 is formed through the first wafer 101 and the dielectric material 102 for electrical connection And to realize chip packaging, make the first low-temperature soldering material 105 at the electr...

Embodiment 2

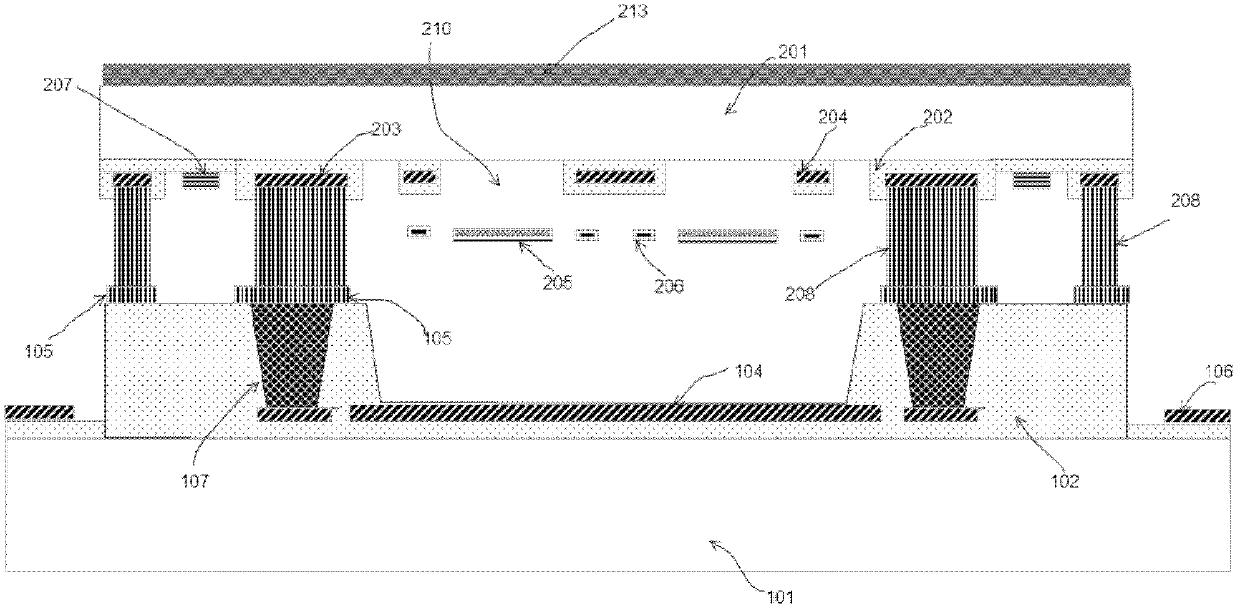

[0078] The structural sectional view of Embodiment 2 of the present invention is as image 3 As shown, the difference from Example 1 lies in the extraction of the last solder joint. The solder joint in Example 1 is extracted from the bottom of the first wafer by the method of TSV. Embodiment 2 is the readout of the first wafer. lead out around the circuit.

[0079] The specific structure is: the first wafer 101 is a conventional silicon wafer, and the readout circuit of the IR FPA is produced by using a conventional IC manufacturing process, and at the same time, the resonance required by the IR FPA device is produced by the uppermost metal of the first wafer 101 Absorbing reflector 104; a dielectric material 102 is deposited on one side of the first wafer 101 with reflector 104, and the dielectric material 102 includes a boss in the middle, and the periphery of the boss is lower than the middle to form an edge, and the boss A TSV structure 103 is formed inside, and a through...

Embodiment 3

[0089] The structural sectional view of embodiment 3 of the present invention is as Figure 4 As shown, its main structure is similar to that of Embodiment 1, the main difference is that the light-condensing integrated microlens is added, thereby increasing the filling factor of the structure and improving the performance of the device.

[0090] The difference in the main production steps is in the seventh step (such as Figure 9-7 As shown), before making the anti-reflection layer material 213, the micro-convex lens array or the Fresnel lens array is made by photolithography and etching, and then the anti-reflection layer material 213 is made to complete the manufacture of the entire device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com