A kind of packaging method of LED chip lens

A technology of LED chip and packaging method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as inappropriateness, and achieve the effects of reducing production costs, simple process, and strong technical operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

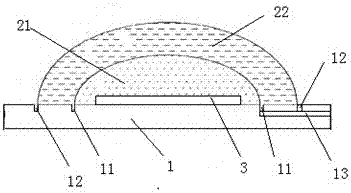

[0014] Such as figure 1 As shown, the encapsulation method of the LED chip lens in this embodiment uses a potting device for encapsulation. The potting device includes a substrate 1, an LED chip 3 mounted on the substrate 1, and a lens wrapped outside the LED chip 3. The lens includes The base layer 21 wrapped outside the LED chip 3 and the stacked layer 22 covering the base layer 21 are composed of a first annular groove 11 and a second annular groove 11 on the substrate 1 and at the outer edges of the base layer 21 and the stacked layer 22 respectively. The annular groove 12, the first annular groove 11 and the second annular groove 12 communicate with each other through the drain groove 13, and the drain port of the drain groove 13 protrudes from the side wall of the substrate 1;

[0015] The packaging method includes the following steps:

[0016] S1: Put the LED chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com