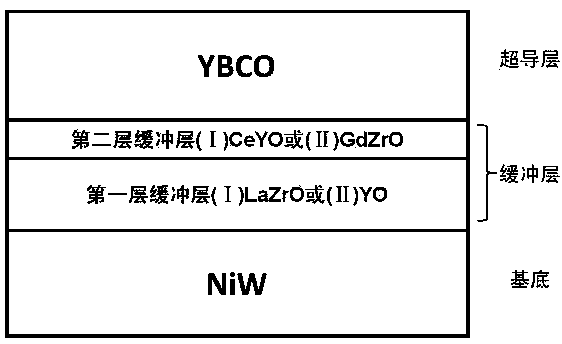

High-temperature superconductive coating conductor dual-layer buffering layer structure and dynamic deposition method thereof

A technology of coated conductors and high-temperature superconductors, applied in superconducting/high-conducting conductors, usage of superconducting elements, coatings, etc., can solve problems such as increasing costs, and achieve diffusion prevention, chemical stability and good structural matching , the effect of uniform texture orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of La by Reactive Magnetron Sputtering 2 Zr 2 o 7 / C 2 Y 2 o 7 Double buffer layer structure.

[0040] A. Ce for sputtering 2 Y 2 o 7 The target material adopts Ce and Y alloy metal targets with an atomic number of 1:1, and La for sputtering 2 Zr 2 o 7 The target is spliced with two semicircles, half of which are La and half Zr. The purity of metal targets and alloy targets is greater than 99.9%.

[0041] B. Pretreatment of the metallic NiW substrate before performing the entire deposition process. at a temperature of 700°C and ArH 2 Carry out heat treatment to metal substrate in the atmosphere, the time of heat treatment is 40 minutes, wherein ArH 2 H in 2 The proportion of the medium is 5%, and the overall air pressure is maintained at 1Pa.

[0042] C. Use the LaZr alloy target first, and before the entire deposition process, vacuum the cavity to 10 -5 Below Pa, then pass Ar5%H into the cavity 2 , the flow rate of the mass flow meter is...

Embodiment 2

[0048] Embodiment 2 utilizes reactive magnetron sputtering to prepare Y 2 o 3 / Gd 2 Zr 2 o 7 Double buffer layer structure.

[0049] A. Gd for sputtering 2 Zr 2 o 7 The target material adopts Gd and Zr alloy metal targets with atomic numbers of 1:1, and the Y for sputtering 2 o 3 The target material is Y metal target, and the purity of metal target material and alloy target material is greater than 99.9%.

[0050] B. The metallic NiW substrate is pretreated before performing the entire deposition process. at a temperature of 700°C and ArH 2 Carry out heat treatment to metal substrate in the atmosphere, the time of heat treatment is 40 minutes, wherein ArH 2 H in 2 The proportion of the medium is 5%, and the overall air pressure is maintained at 1Pa.

[0051] C. Use the Y target first, and before the entire deposition process, evacuate the cavity to less than 10 -5 Below Pa, then pass Ar5%H into the cavity 2 , the flow rate of the mass flowmeter is 350 SCCM, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com