Application of chemical plating nickel phosphorus alloy to triallyl cyanurate (TAC) film production line

An electroless nickel-phosphorus plating production line technology, applied in the application field of electroless nickel-phosphorus alloy plating on the TAC film production line, can solve problems such as difficult to ensure the quality of the coating, and achieve the effects of good corrosion resistance, high smoothness, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The application method of electroless nickel-phosphorus alloy on the drying box frame of the TAC film production line, the steps are:

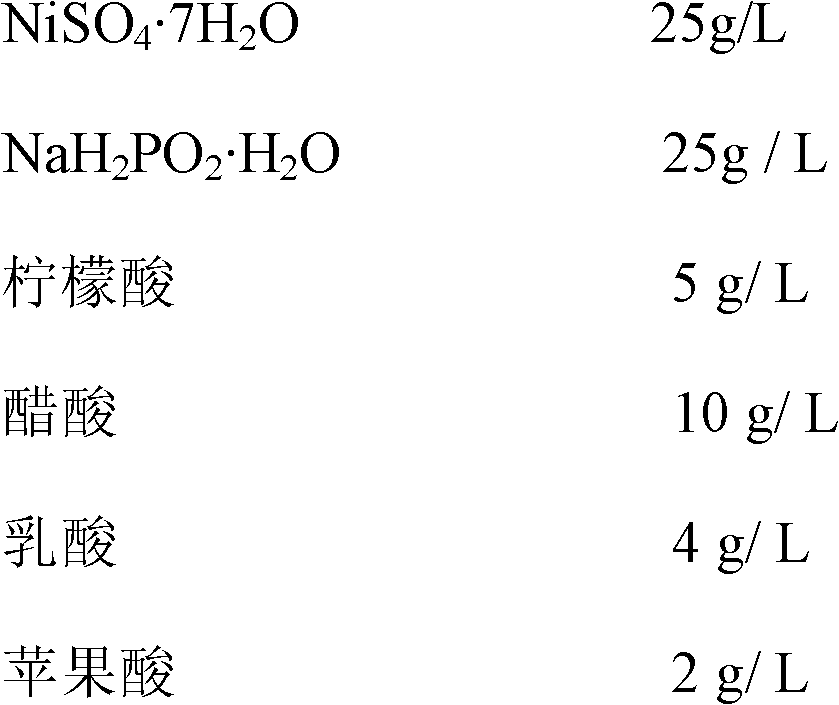

[0024] (1), prepare the plating solution, the composition of electroless nickel-phosphorus alloy solution is:

[0025]

[0026] (2) Pre-treatment of the ordinary carbon steel surface of the drying box frame, the specific steps include:

[0027] ①Surface rust removal: perform mechanical grinding and sandblasting rust removal treatment on the surface of the workpiece;

[0028] ②Alkaline washing and degreasing: put the workpiece into alkaline washing solution at 80℃ for 3 hours to wash off the oil stains on the surface. Each liter of the alkaline washing solution contains 15g NaOH and 25gNa 3 PO 4 ;

[0029] ③ Wash with water;

[0030] ④Local surface protection: apply LX-06 paint (purchased from Shandong Lanxing Cleaning and Anti-Corrosion Co., Ltd.) on the parts that do not need electroless plating. This paint can prevent the occur...

Embodiment 2

[0042] The application method of electroless nickel-phosphorus alloy on the drying box frame of the TAC film production line, the steps are:

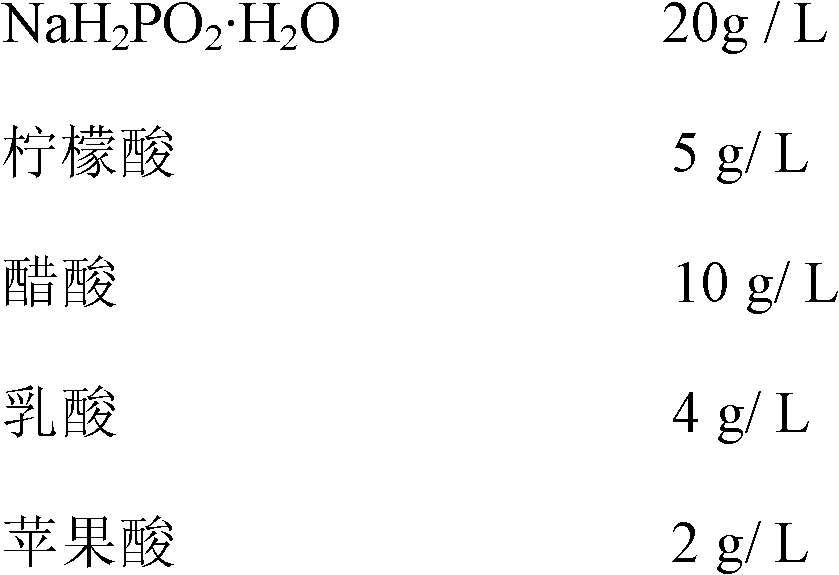

[0043] (1), prepare the plating solution, the composition of electroless nickel-phosphorus alloy solution is:

[0044]

[0045]

[0046] (2) Pre-treatment of the ordinary carbon steel surface of the drying box frame, the specific steps include:

[0047] ①Surface rust removal: perform mechanical grinding and sandblasting rust removal treatment on the surface of the workpiece;

[0048] ②Alkaline washing and degreasing: put the workpiece into alkaline washing solution at 80℃ for 2 hours to wash off the oil stains on the surface. Each liter of the alkaline washing solution contains 20g NaOH and 35gNa 3 PO 4 ;

[0049] ③ Wash with water;

[0050] ④Local surface protection: apply LX-06 paint (purchased from Shandong Lanxing Cleaning and Anti-Corrosion Co., Ltd.) on the parts that do not need electroless plating. This paint can preve...

Embodiment 3

[0062] The application method of electroless nickel-phosphorus alloy on the drying box frame of the TAC film production line, the steps are:

[0063] (1), prepare the plating solution, the composition of electroless nickel-phosphorus alloy solution is:

[0064]

[0065] (2), the difference between the common carbon steel surface pretreatment steps of the drying box frame and the embodiment 1 is:

[0066] ②Alkaline washing and degreasing: Put the workpiece into alkaline washing solution at 80℃ for 4 hours to wash off the oil stains on the surface. Each liter of the alkaline washing solution contains 18g NaOH and 30gNa 3 PO 4 ;

[0067] ⑥Pickling and rust removal: add hydrochloric acid solution with a mass concentration of 10% in the plating tank as the tank liquid, add the workpiece into it for pickling for 2 hours, and remove the floating rust;

[0068] ⑧ Pickling activation: the bath liquid is replaced with a hydrochloric acid solution with a mass concentration of 15%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com