Ru sputtering target with high purity and preparation method thereof

A sputtering target and high-purity technology, applied in the field of powder metallurgy, can solve the problems of unusable molds, increase production costs, large losses, etc., and achieve the effects of reducing abnormal discharge phenomena, saving production costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention has prepared the above-mentioned high-purity ruthenium sputtering target material through the following method. The ruthenium sputtering target is prepared by a two-way vacuum hot pressing method. The specific preparation method includes the following steps:

[0033] (1) Powder pretreatment: the high-purity ruthenium powder is ball milled and graded, and the particle size of the ruthenium powder for the sintered target is 1-10 μm;

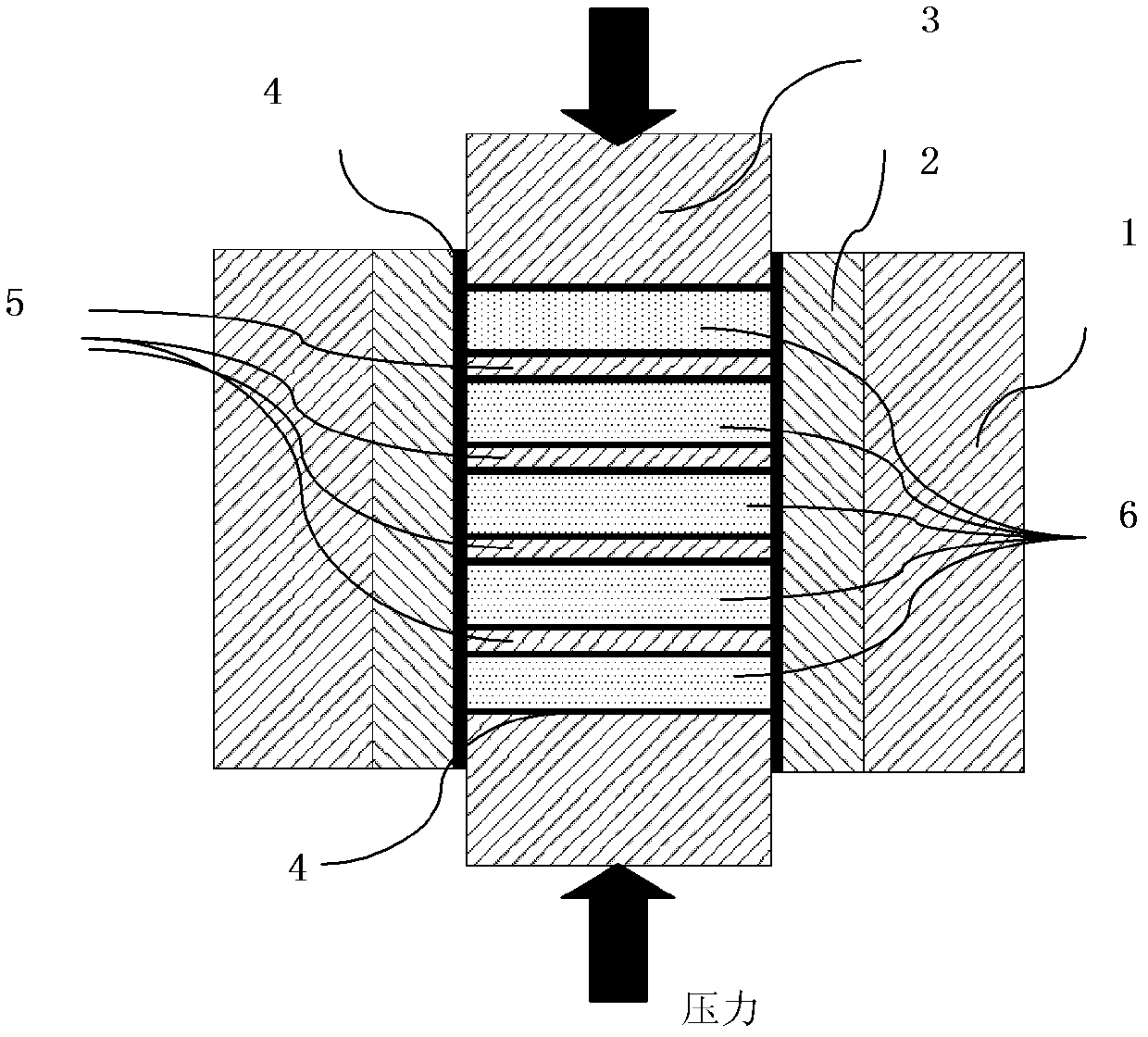

[0034] (2) powder filling: the ruthenium powder is filled in the graphite mold through the powder loading device;

[0035] (3) Powder sintering: send the mold containing high-purity ruthenium powder into a vacuum hot-pressing sintering furnace for two-way vacuum hot-pressing sintering with a vacuum degree of 10 -2 ~10 -4 pa, the sintering temperature is 1100-1800°C, the sintering pressure is 30-60MPa, and the holding time is 1-5h.

[0036] The ball mill crushing technique of described high-purity ruthenium powder is t...

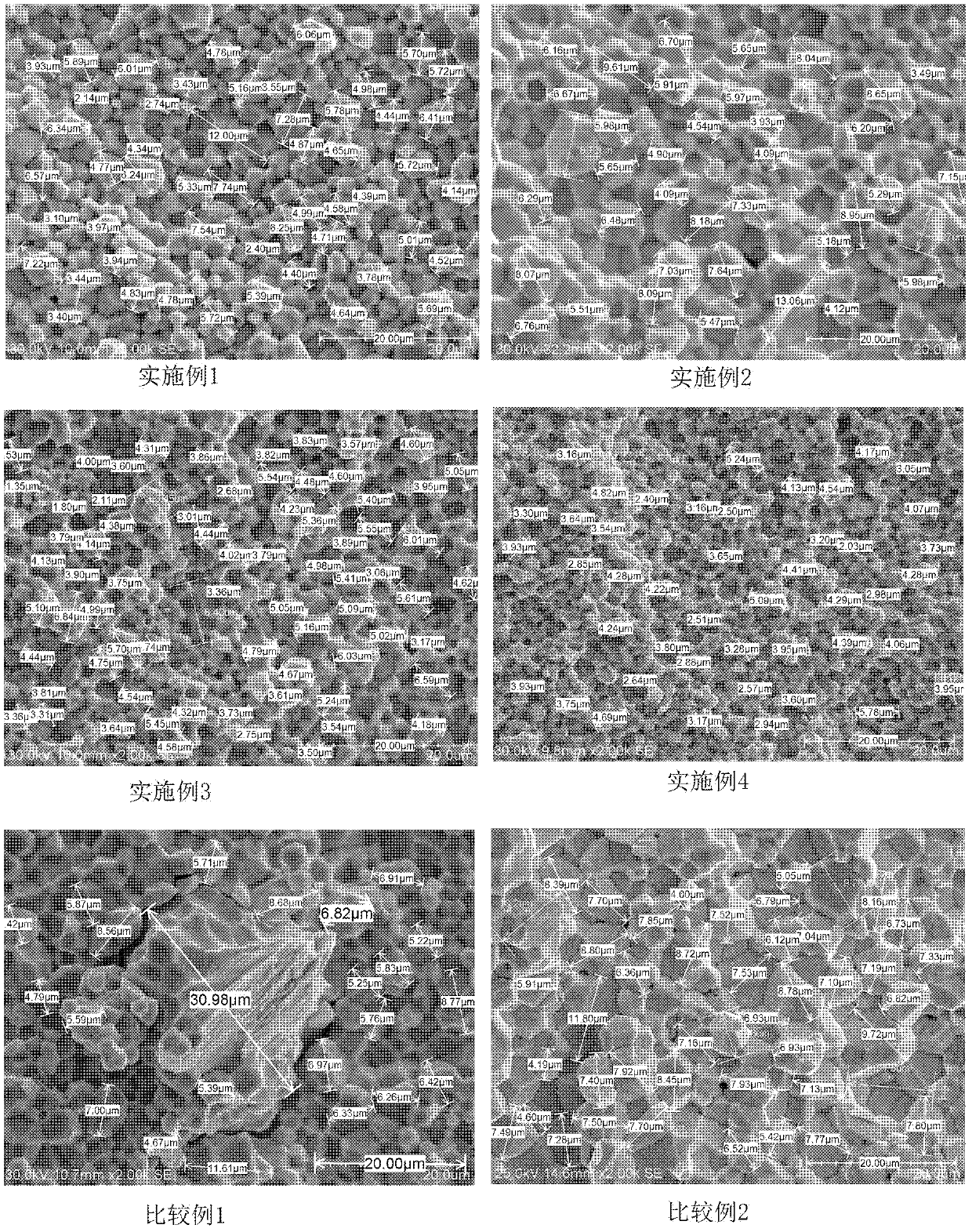

Embodiment 1

[0042] The high-purity ruthenium sputtering target of the present invention is made through the following steps:

[0043](1) Powder pretreatment: select high-purity Ru powder with a purity of 3N5, and carry out planetary ball milling to the high-purity Ru powder. The grinding medium is yttrium-stabilized zirconia balls with a diameter of 2 mm and a ball-to-material ratio of 3: 1 (mass ratio), the revolution speed of the ball mill is 500rpm, and the ball milling time is 5min. After the ball milling, the ruthenium powder with a particle size of 1-10 μm is obtained and used as raw material powder.

[0044] (2) Powder filling: put the raw material powder required for 5 targets into the graphite mold through the powder filling device (such as figure 1 shown), the middle is separated by a graphite gasket, and 5 targets are pressed and formed at the same time.

[0045] (3) Powder sintering process: Put the graphite mold filled with Ru powder into the furnace body of vacuum two-way h...

Embodiment 2

[0047] The difference from Example 1 is that the ball mill crushing process is as follows: the diameter of the yttrium stabilized zirconia ball is 6 mm, the ball-to-material ratio is 6:1, the ball mill speed is 400 rpm, and the ball mill crushing time is 30 min. The sintering process is as follows: the sintering temperature is 1800°C, the sintering pressure is 30MPa, and the sintering vacuum is 10 -2 ~10 -3 Pa, from room temperature to 600°C, the heating rate is 15°C / min, keep at 600°C for 30 minutes, then continue to increase the temperature, the heating rate is 10°C / min, when the temperature rises to 1300°C, keep the temperature for 1 hour, and then continue Raise the temperature at a rate of 5°C / min. When the temperature rises to 1800°C, keep it at this temperature for 1 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com