Preparation method of silicone rubber composite material with fluorescence

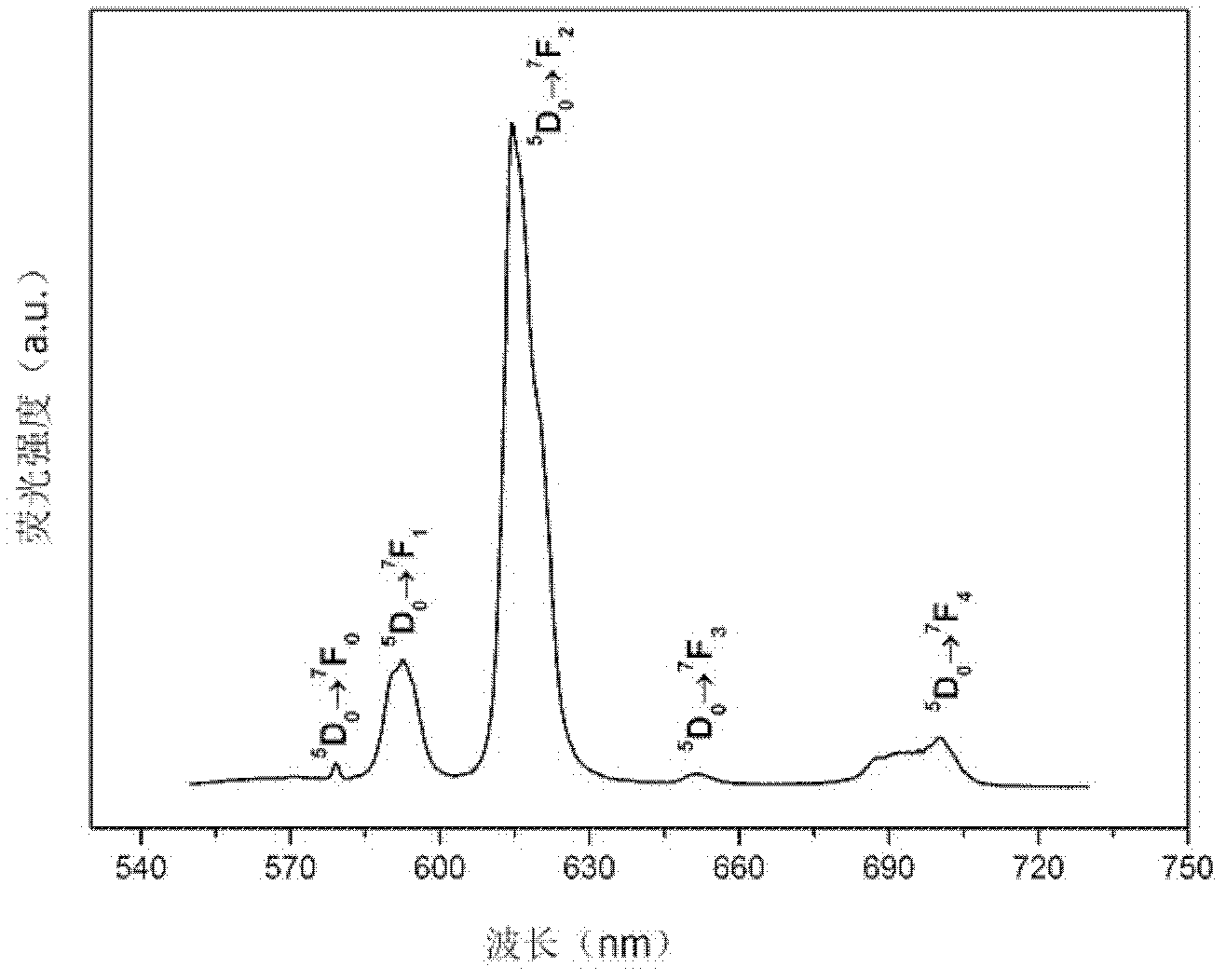

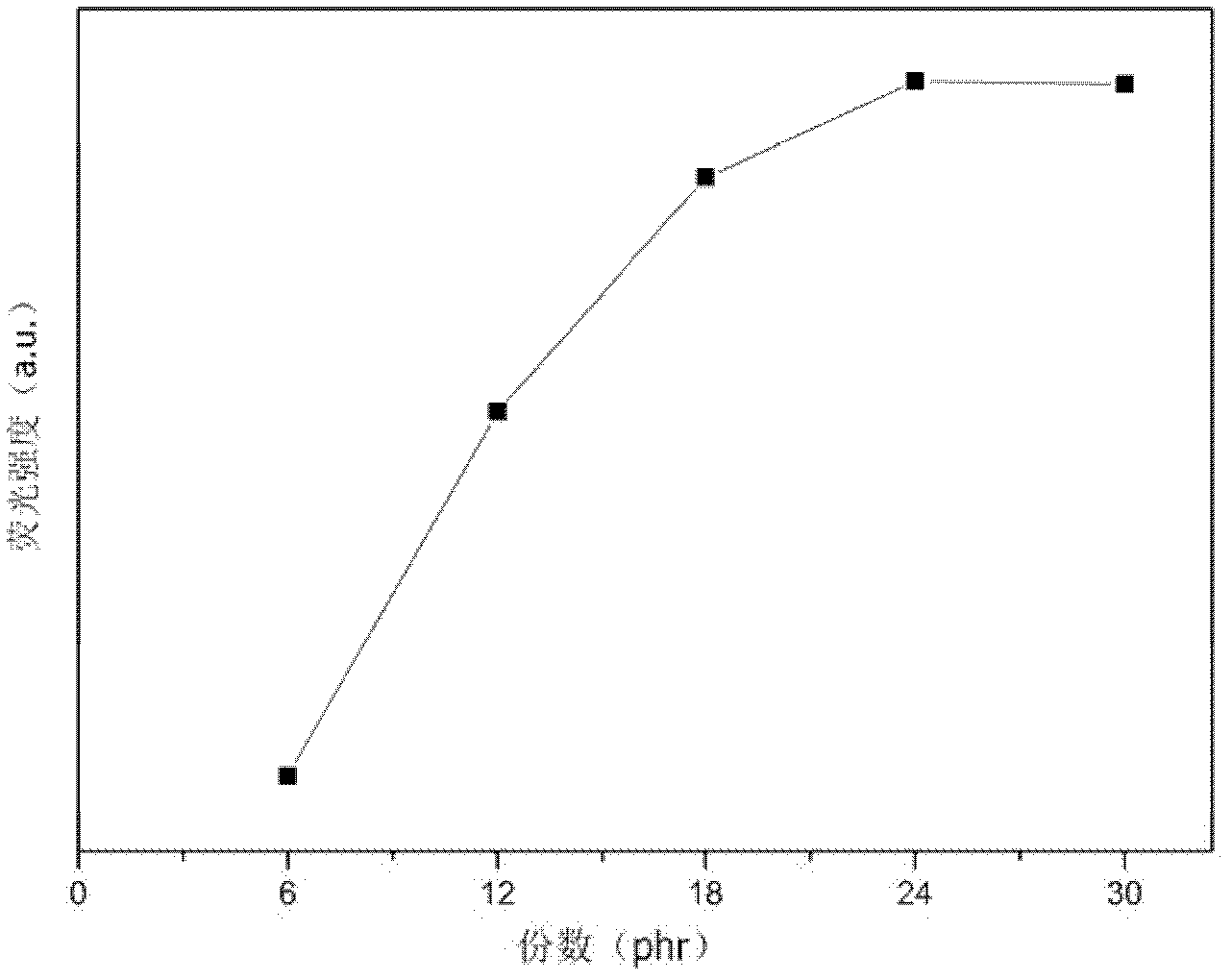

A composite material and fluorescence performance technology, applied in the field of preparation of functional polymer materials, can solve the problems of low fluorescence intensity and low absorption coefficient, and achieve the effects of increasing doping concentration, increasing fluorescence lifetime and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

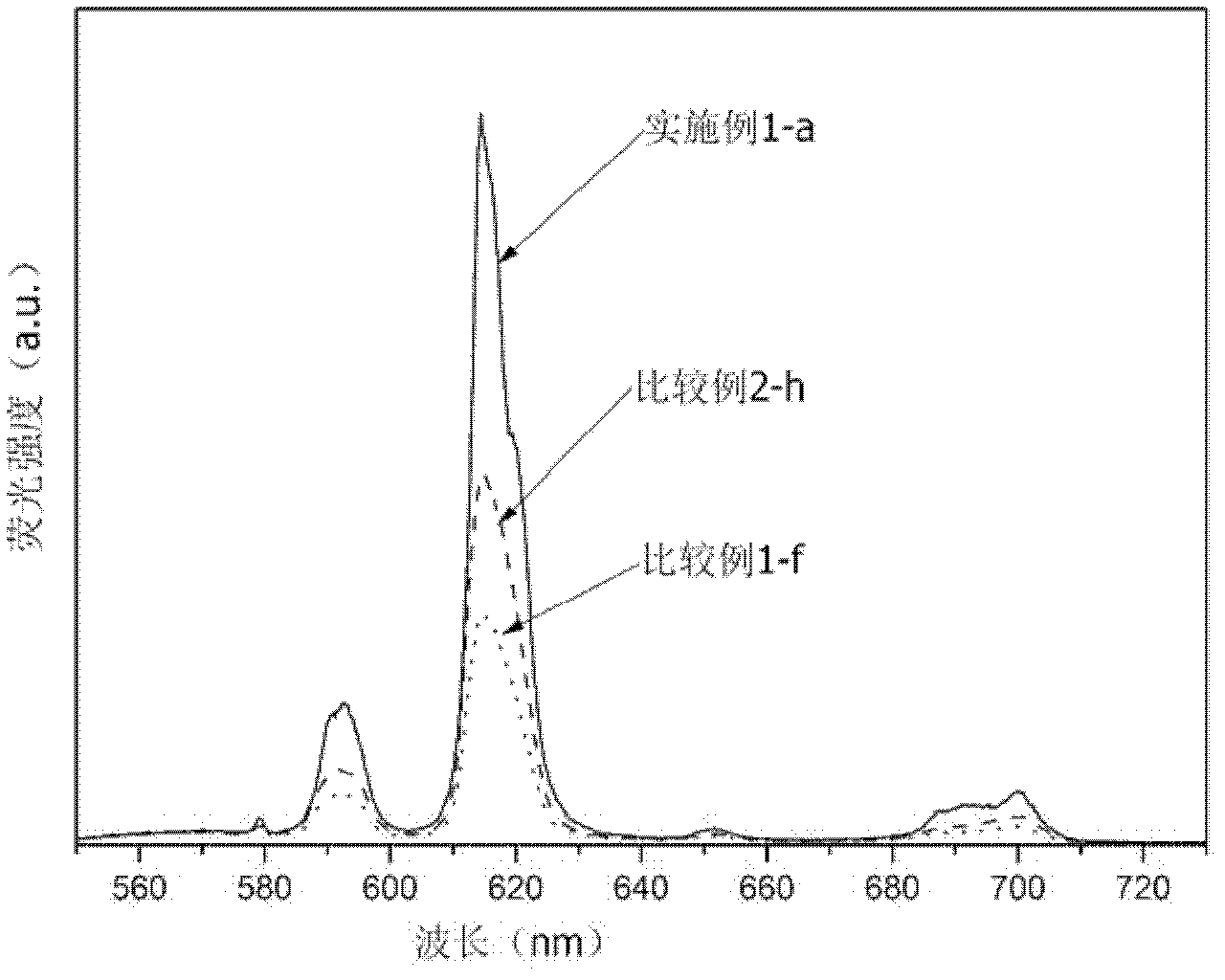

Examples

Embodiment 1

[0035] (1) Preparation of mixed powder of rare earth complexes and mesoporous silica

[0036] Add 6.0 g of polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (P123), 180 mL of 2 mol / L HCl, and 45 mL of deionized water into the flask, and stir at 40°C until P123 is completely dissolved. Add 13.0 g of tetraethyl orthosilicate into the flask, keep the temperature constant, and stir for 24 hours. Then, the temperature was raised to 90°C, stirring was stopped, and crystallization was carried out for 24 hours. The reacted product was separated by suction filtration, washed several times with deionized water, and the powder after suction filtration was extracted at 130° C. for 24 hours using ethanol as a solvent. Place the extracted powder in a vacuum oven and dry at 80°C for 6 hours to obtain mesoporous silica SBA-15;

[0037] 5 mmol of europium oxide (Eu 2 o 3 ) and 6 mL of 12 mol / L HCl and 6 mL of deionized water were stirred at 80-90° C. for about 3 h. Heating wa...

Embodiment 2

[0050] A preparation method of a silicone rubber composite material with fluorescent properties, comprising the following steps:

[0051] (1) Preparation of rare earth complex doped mesoporous silica mixed powder

[0052] a. Using polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer as template and tetraethyl orthosilicate as raw material to prepare mesoporous silica SBA-15, the specific steps are as follows:

[0053] Add polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (P123), 2mol / L HCl, and deionized water into the flask, wherein the polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer The weight ratio of HCl to deionized water is 1:7, and the volume ratio of HCl to deionized water is 3:1. At 40°C, stir until P123 is completely dissolved, then add tetraethyl orthosilicate into the flask, orthosilicate The weight ratio of acid tetraethyl ester to polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer is 2:1, the temperature ...

Embodiment 3

[0060] A preparation method of a silicone rubber composite material with fluorescent properties, comprising the following steps:

[0061] (1) Preparation of rare earth complex doped mesoporous silica mixed powder

[0062] a. Using polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer as template and tetraethyl orthosilicate as raw material to prepare mesoporous silica SBA-15, the specific steps are as follows:

[0063] Add polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer (P123), 2mol / L HCl, and deionized water into the flask, wherein the polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer The weight ratio of HCl to deionized water is 1:8, and the volume ratio of HCl to deionized water is 5:1. At 40°C, stir until P123 is completely dissolved, then add tetraethyl orthosilicate into the flask, orthosilicate The weight ratio of acid tetraethyl ester to polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer is 3:1, the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com