Environmental-friendly low-smoke and low-halogen mining cable sheath rubber skin

A cable sheath rubber, environmentally friendly technology, used in insulated cables, cables, circuits, etc., can solve problems such as blood poisoning, stimulation of the respiratory system, and narrow underground environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

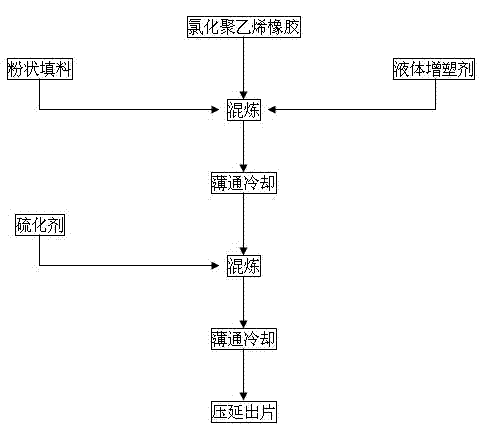

Method used

Image

Examples

Embodiment 1

[0014] A colored and environment-friendly low-smoke and low-halogen mine cable sheath rubber, which includes the following components and parts by weight: 100 parts of chlorinated polyethylene rubber, 15 parts of magnesium oxide, 5 parts of environmentally friendly calcium-zinc stabilizer, and microcrystalline wax 5 parts, 20 parts of white carbon black, 20 parts of nano clay, 20 parts of aluminum hydroxide, 20 parts of environmentally friendly aluminum-magnesium composite flame retardant, 5 parts of DCP, 3 parts of PDM, 1 part of RD, 10 parts of IPPP, benzidine yellow or Fast red 3 parts. It works well with the sheath.

[0015] A black environment-friendly cable sheath rubber for low-smoke and low-halogen mines, comprising the following components and parts by weight: 100 parts of chlorinated polyethylene rubber, 15 parts of magnesium oxide, 5 parts of environmentally friendly calcium-zinc stabilizer, and 5 parts of microcrystalline wax 15 parts of white carbon black, 5 part...

Embodiment 2

[0017] A colored and environment-friendly low-smoke and low-halogen mine cable sheath rubber, which includes the following components and parts by weight: 100 parts of chlorinated polyethylene rubber, 10 parts of magnesium oxide, 3 parts of environmentally friendly calcium-zinc stabilizer, and microcrystalline wax 8 parts, 15 parts of white carbon black, 15 parts of nano clay, 15 parts of aluminum hydroxide, 15 parts of environmentally friendly aluminum-magnesium composite flame retardant, 3 parts of DCP, 5 parts of PDM, 2 parts of RD, 15 parts of IPPP, benzidine yellow or resistant Sun red 5 copies.

[0018] A black environment-friendly low-smoke and low-halogen mine cable sheath rubber, comprising the following components and parts by weight: 100 parts of chlorinated polyethylene rubber, 10 parts of magnesium oxide, 3 parts of environmentally friendly calcium-zinc stabilizer, and 8 parts of microcrystalline wax 15 parts of white carbon black, 10 parts of carbon black, 15 par...

Embodiment 3

[0020] A colored and environment-friendly low-smoke and low-halogen mine cable sheath rubber, which includes the following components and parts by weight: 100 parts of chlorinated polyethylene rubber, 12 parts of magnesium oxide, 4 parts of environmentally friendly calcium-zinc stabilizer, and microcrystalline wax 6 parts, 25 parts of white carbon black, 25 parts of nano clay, 25 parts of aluminum hydroxide, 25 parts of environmentally friendly aluminum-magnesium composite flame retardant, 4 parts of DCP, 4 parts of PDM, 2 parts of RD, 12 parts of IPPP, benzidine yellow or Fast red 4 parts.

[0021] A black environment-friendly cable sheath rubber for low-smoke and low-halogen mines, comprising the following components and parts by weight: 100 parts of chlorinated polyethylene rubber, 12 parts of magnesium oxide, 4 parts of environmentally friendly calcium-zinc stabilizer, and 6 parts of microcrystalline wax 25 parts of white carbon black, 8 parts of carbon black, 25 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com