Rare-earth-doped chalcogenide (halogen) thin film material, preparation method and application

A technology of rare earth doping and thin-film materials, applied in active medium materials, instruments, optics, etc., can solve the problems of short energy level life, weak emission, low quantum efficiency, etc., and achieve uniform distribution of components, easy control of components, The effect of prolonging the luminous life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below through examples in conjunction with the accompanying drawings, but the present invention is not limited to the examples given.

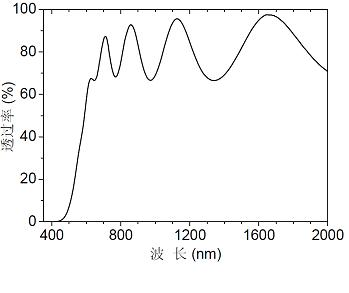

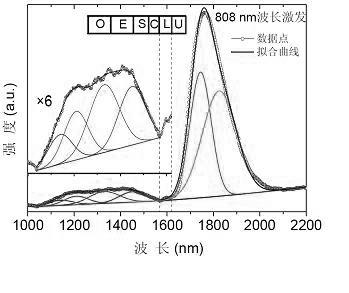

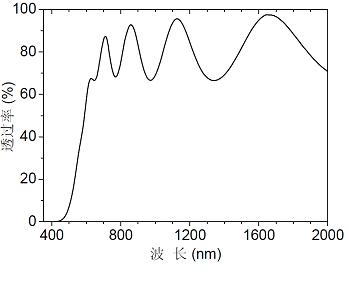

[0020] In this example, Dy was first prepared by traditional melt quenching technique 3+ Ion and Tm 3+ Ion co-doped chalcogenide (halogen) glass bulk material, which is then cut into cylindrical shapes with a thickness of about 5 ± 2 mm and a diameter of about 10 ± 4 mm, the surface of which is polished to a mirror surface, and is used as a thin film Prepared targets. In the specific experiment process, the glass target composition is designed to be 72GeS 2 18Ga 2 S 3 10CdI 2 (mol%), Tm 3+ and Dy 3+ The doping concentrations are designed to be 1.0 wt% and 0.4 wt%. Subsequently, in the vacuum coating chamber, the required chalcogenide (halogen) thin film material is prepared by pulse laser deposition technology. Specifically, it is carried out in a vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com