Ectopic leaching restoring device and restoring method for chromic slag polluted soil

A technology for polluted soil and soil leaching, applied in the field of collection and leaching, can solve the problems of inability to fundamentally remove chromium, inability to operate continuously, and low degree of automation, reducing labor input, high degree of equipment integration, and degree of automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

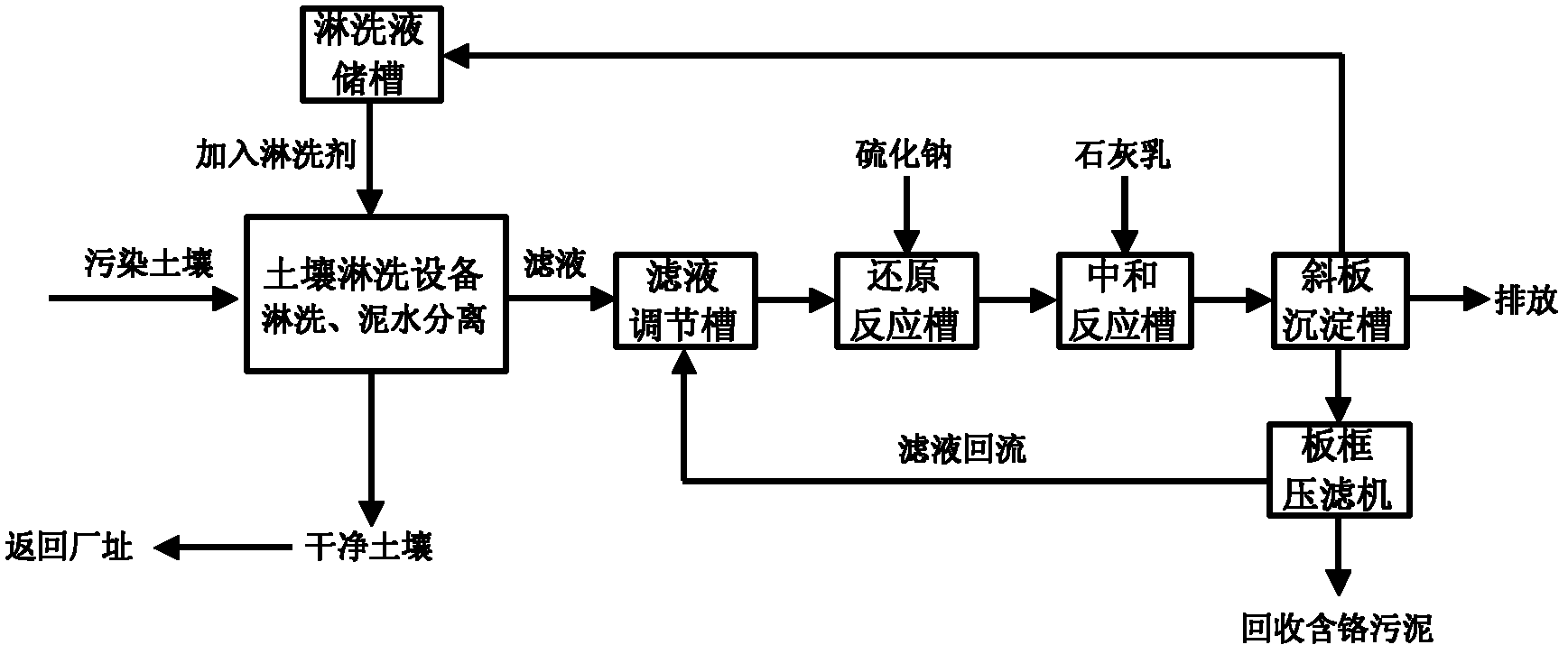

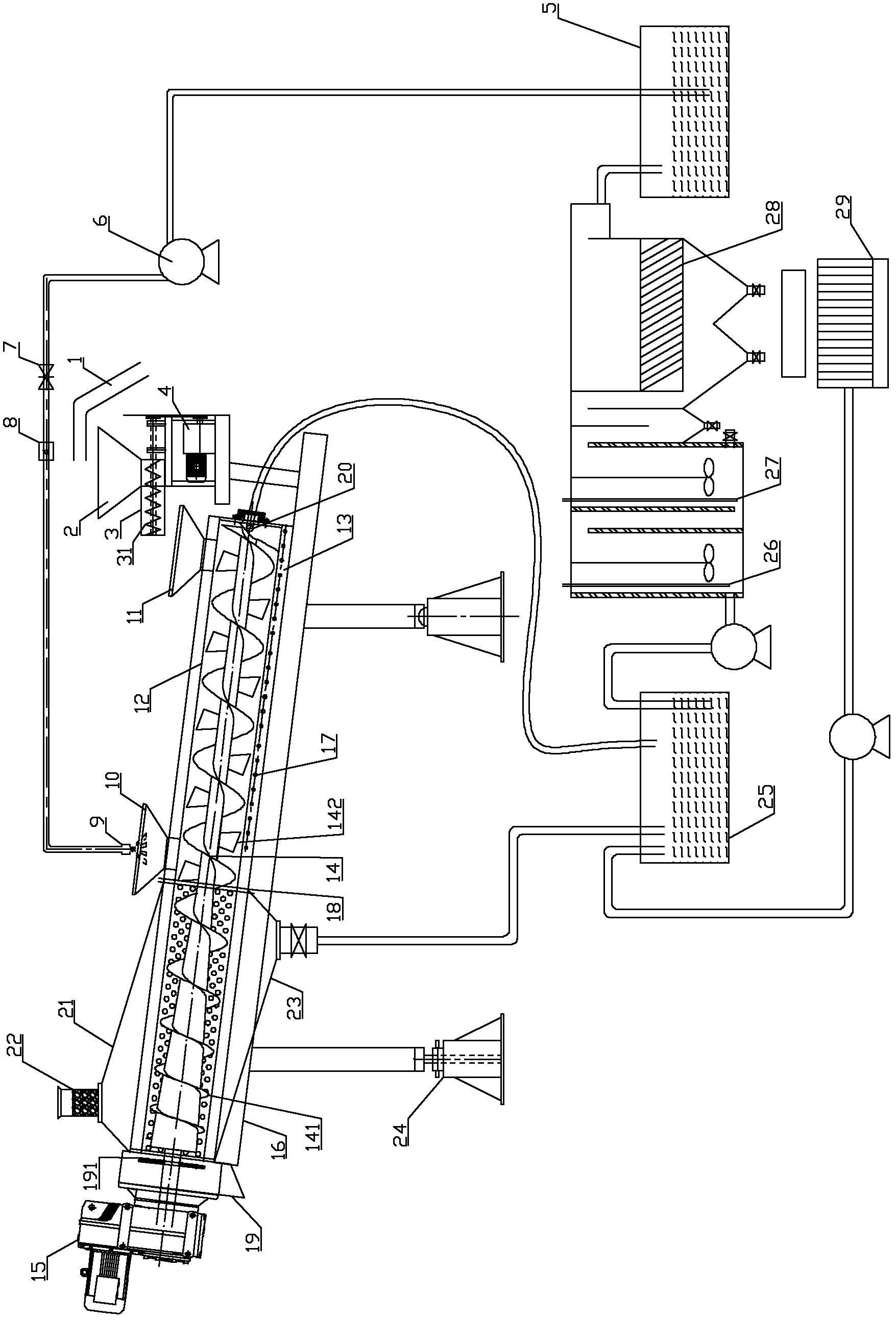

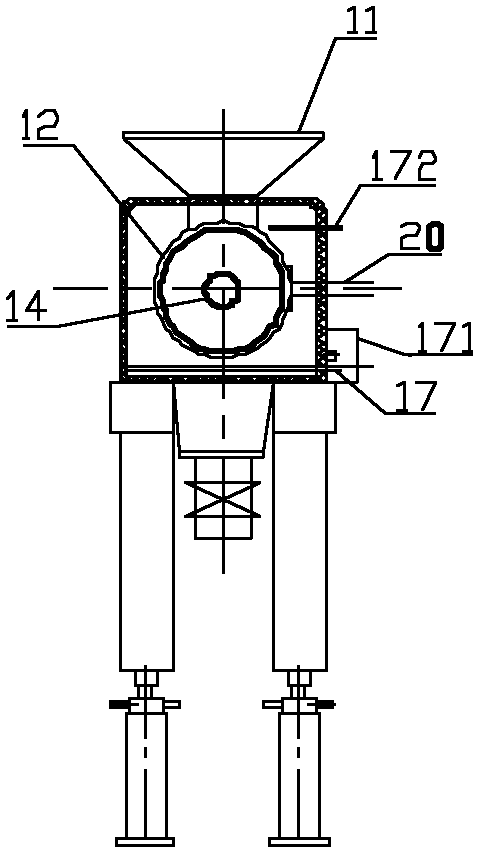

[0047] The chromium slag contaminated soil ectopic leaching repair equipment consists of a feeding system, a soil leaching-dehydration system, a waste gas treatment system, a eluent collection and treatment system, and an automatic control system. The feeding system includes a soil feeding device and a washing agent adding device, wherein the soil feeding device is composed of a feeding hopper 2, a delivery pipe 3, a delivery stirring shaft 31 and a motor 4, and the bottom of the feeding hopper 2 is connected with the delivery pipe 3, The conveying stirring shaft 31 is arranged in the conveying pipe 3, and the motor 4 is arranged at the outer end of the conveying pipe 3, and the conveying stirring shaft 31 is driven to transport the contaminated soil evenly to the reaction cylinder 12 for rinsing; The storage tank 5, the water pump 6, and the atomizing nozzle 9 are composed. The leaching agent storage tank 5 is connected to the soil leaching-dehydration system through a pipelin...

Embodiment 2

[0049] Contaminated soil first enters the feed hopper 2 through the hoist 1, and then the soil is evenly added to the washing section of the reaction cylinder from the soil feed port 11 on the reaction cylinder 12 by the conveying stirring shaft 31, and is stirred by the stirring paddle 142. Fully mix and contact with the eluent remaining at the end of the soil feed port 11, and use the heating chamber 13 to increase the eluting reaction temperature, enhance the eluting effect, and initially realize the transfer of the chromium-containing components in the soil to the eluent. the liquid phase. With the rotation of the spiral stirring propeller 14, the contaminated soil fully mixed with the eluent moves to the high-end discharge port, and in this process forms a reverse flow with the eluent added from the end of the eluent section to realize the decontamination of the soil. The second leaching further reduces the chromium content in the soil. When the mud-water mixture is tran...

Embodiment 3

[0051] Taking the polluted soil around the chromium slag dump of a chemical plant in Sanmenxia, Henan as an example, the content of hexavalent chromium in the sample was 8.73mg / g. Put the soil into the feed hopper, turn on the water pump, add 0.1mol / L citric acid aqueous solution as the eluting agent into the reaction cylinder, adjust the tilt angle of the equipment at 5°, and the inner screen mesh diameter of the dehydration section is 0.5mm, so that the reaction After there is a certain amount of eluent at the feed end of the cylinder, turn on the screw agitator in the feeding system, set the rotation speed of the agitator, and add the soil evenly into the reaction cylinder, and at the same time adjust the flow rate of the eluent according to the soil-water ratio of 1:4 At the same time, turn on the motor that controls the screw agitating propeller, set the rotation speed of the screw agitating propeller to 4rpm, control the rinsing temperature at 50°C through the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com