Air filter material based on carbon nano tube and preparation method thereof

An air filter material, carbon nanotube technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the damage of the intrinsic properties of carbon nanotubes, increase the resistance of carbon nanotube membranes, and affect the carbon nanotube membranes. Quality and other issues, to achieve good industrial application prospects, avoid material size and shape limitations, and achieve the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

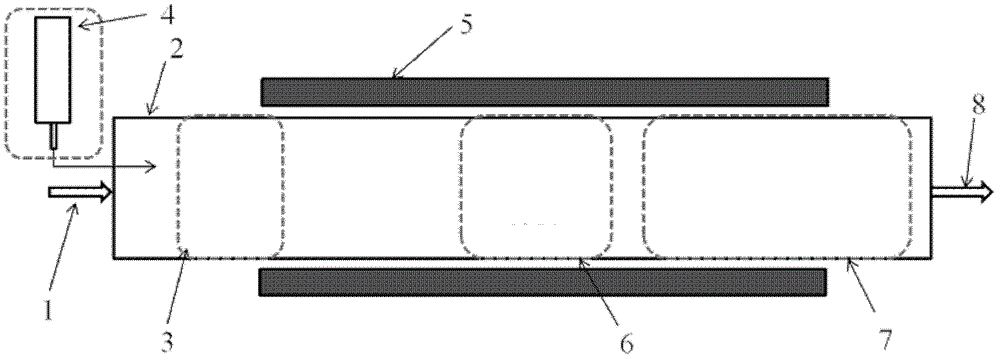

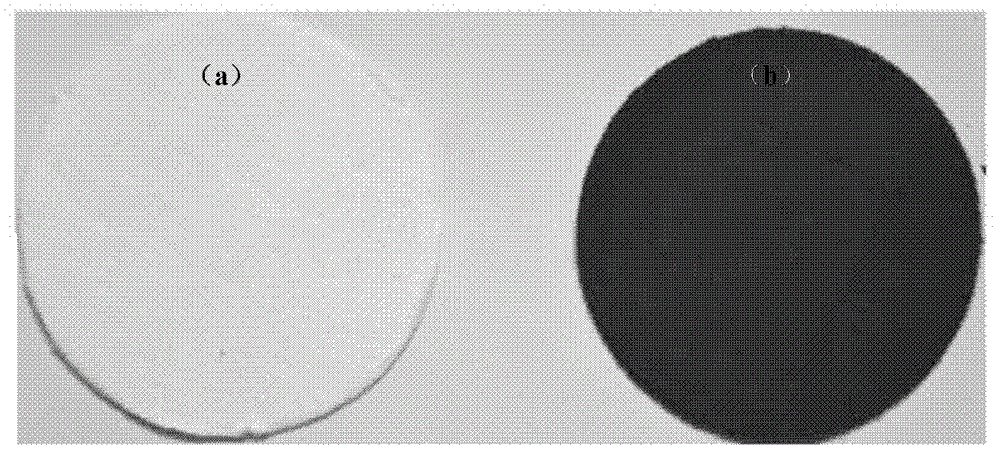

[0032] Embodiment 1, take the quartz fiber filter medium as the base to prepare carbon nanotube air filter material

[0033] The quartz fiber filter media (such as figure 2 As shown in (a), the average diameter of the quartz fiber is 3 μm), placed in the heating section of the quartz sleeve (such as figure 1 position shown in middle 6); take ferrocene as catalyst, place the nozzle of quartz tube (such as figure 1 3), the temperature at the position of the catalyst during the reaction is 120°C; with argon and hydrogen as the protective atmosphere, ethylene as the carbon source, the ratio is argon: hydrogen: ethylene = 7: 1: 2, gas flow rate 3mm / s, heat up to 760°C, and react for 1 hour to obtain an air filter material based on carbon nanotubes, such as figure 2 Shown in (b), wherein the average diameter of carbon nanotubes is 25nm.

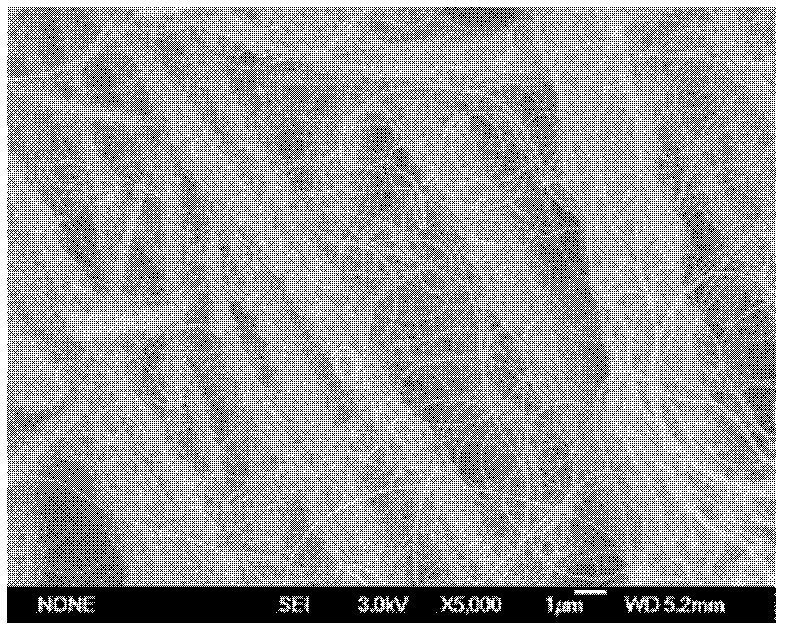

[0034] The scanning electron micrograph of the air filter material based on carbon nanotubes prepared by the present embodiment is as follows...

Embodiment 2

[0037] Embodiment 2, take carbon fiber filter medium as base preparation carbon nanotube air filter material

[0038] Place the carbon fiber filter medium (the average diameter of the carbon fiber is 5 μm, in the shape of folded cloth) in the heating section of the quartz sleeve (such as figure 1 position shown in middle 6); take ferrocene as catalyst, place the nozzle of quartz tube (such as figure 1 3), the temperature at the position of the catalyst during the reaction is 120°C; with argon and hydrogen as the protective atmosphere, ethylene as the carbon source, the ratio is argon: hydrogen: ethylene = 7: 1: 2, gas flow rate The temperature is 3 mm / s, the temperature is raised to 850° C., and the reaction is performed for 15 minutes to obtain an air filter material based on carbon nanotubes. The average diameter of the carbon nanotubes is 25 nm.

Embodiment 3

[0039] Embodiment 3, take the quartz fiber filter medium after folding as base preparation carbon nanotube air filter material

[0040] Place the folded quartz fiber filter medium (the average diameter of the quartz fiber is 3 μm) in the heating section of the quartz sleeve (such as figure 1 position shown in middle 6); take ferrocene as catalyst, place the nozzle of quartz tube (such as figure 1 3), the temperature at the position of the catalyst during the reaction is 120°C; with argon and hydrogen as the protective atmosphere, ethylene as the carbon source, the ratio is argon: hydrogen: ethylene = 7: 1: 2, gas flow rate The temperature is 3 mm / s, the temperature is raised to 760° C., and the reaction is performed for 1 hour to obtain an air filter material based on carbon nanotubes. The average diameter of the carbon nanotubes is 25 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com