Nano imprinting device and method for imaging sapphire substrate

A sapphire substrate and nano-imprinting technology, which is applied to the exposure device of photoengraving process, photoengraving process of pattern surface, instruments, etc., can solve the problems of limited service life, high interfacial dislocation density, lattice mismatch, etc. , to achieve the effect of long service life, good light transmission performance and long service life of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments given by the inventor according to the technical solution of the present invention.

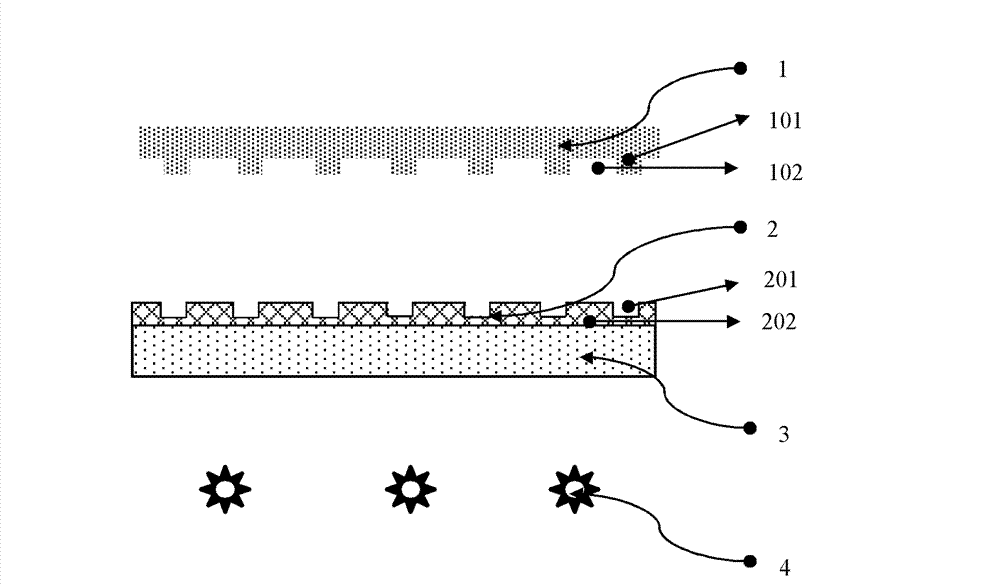

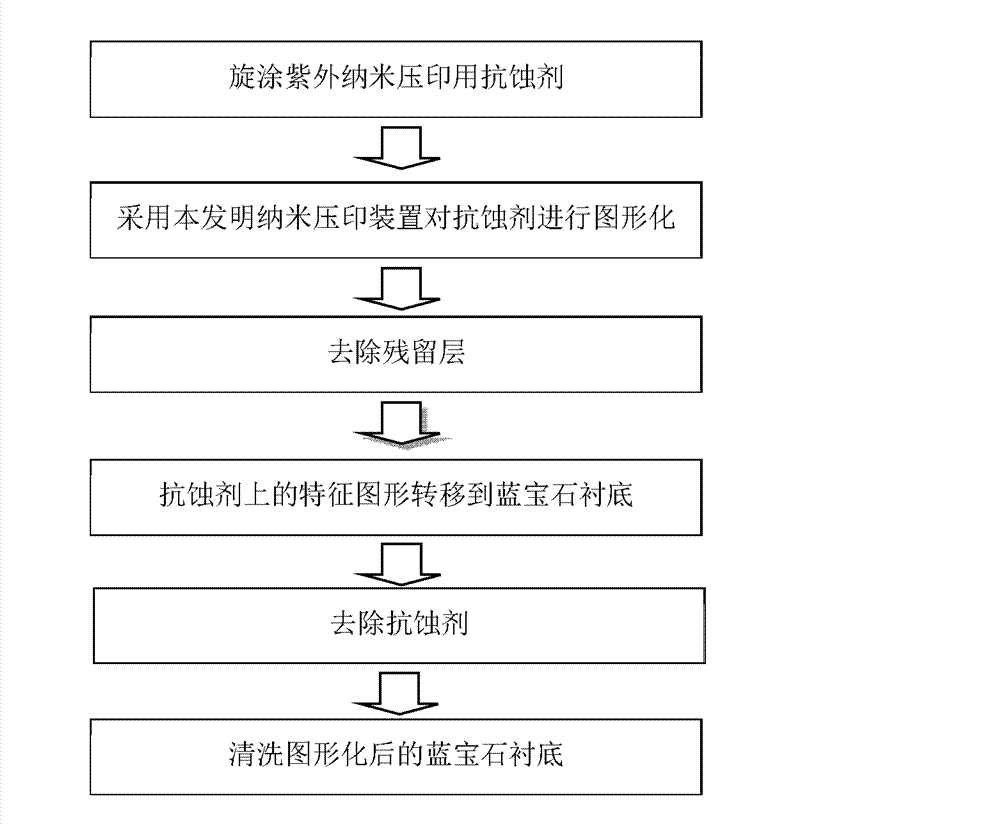

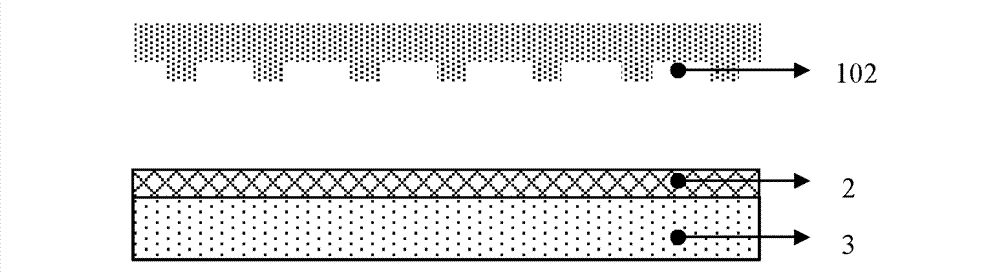

[0046] figure 1 , figure 2 , Figure 3A-Figure 3G with Figure 4A-Figure 4H , taking a 4-inch (about 100 mm) nano-patterned sapphire substrate 3 as an example, the implementation of wafer-level nano-patterning using the UV nanoimprint process based on a modified fluorocarbon resin-based hard polymer mold is described in detail. An imprinting device for a sapphire substrate and a manufacturing method thereof.

[0047] figure 1 Among them, a wafer-level nano-patterned sapphire substrate imprinting device, which includes: from top to bottom: a modified nano-imprint mold 1, a resist 2 for ultraviolet nano-imprinting, a sapphire substrate 3, UV light source 4 for exposure. Wherein, the resist 2 is coated on the sapphire substrate 3, the ultraviolet light s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com