Method for preparing thin-walled ceramic crucible

A ceramic crucible and thin-walled technology, which is applied in the field of preparation of thin-walled ceramic crucibles, can solve the problems of neurotoxicity of monomers and functional cross-linked bodies, harsh process control conditions, and easy production of waste products, so as to reduce cracking easily and simplify The effect of post-processing and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

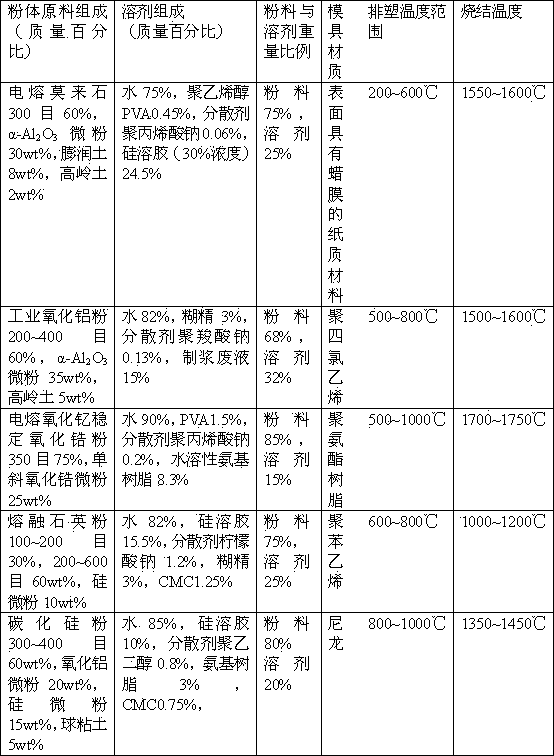

Embodiment 1

[0021] The solid ceramic powder by mass percentage: fused mullite (300 mesh) 60 wt%, α-Al 2 o 3 Micropowder (D50=3μm) 30wt%, bentonite 8wt%, kaolin 2wt% are fully mixed to make a uniform ceramic powder.

[0022] The solvent is composed of 75% water, 0.45% polyvinyl alcohol PVA, 0.05% sodium polyacrylate as a dispersant, and 24.5% silica sol (30% concentration).

[0023] The proportion of powder and solvent by weight: powder 75%, solvent 25%, and a uniform ceramic slurry is made by fully stirring.

[0024] Select a paper blister mold with a layer of wax pattern on the inner wall, coat a layer of water-absorbing resin film on its surface, pour the mixed ceramic slurry on the surface of the paper mold until the mold is covered with ceramic slurry, static Set the mold to absorb water, make the green body reach a certain thickness by repeated pouring, and then dry it. Send the dried biscuit together with the paper mold into a high-temperature firing furnace for sintering, raise ...

Embodiment 2

[0026] According to the mass percentage of solid powder: industrial alumina powder 200~400 mesh 60wt%, α-Al 2 o 3 35wt% of fine powder and 5wt% of kaolin are fully mixed to make a uniform ceramic powder.

[0027] The solvent is composed of 82% water, 3% dextrin, 0.13% sodium polycarboxylate dispersant, 0.005% sodium dodecylbenzenesulfonate, and 11.865% pulping waste liquid.

[0028] The weight ratio of the powder and the solvent is 68% of the powder and 32% of the solvent, and a uniform ceramic slurry is made by fully stirring.

[0029] Choose a mold made of polytetrafluoroethylene, coat a layer of water-absorbing resin film on its surface, fully put the processed mold in the mixed ceramic slurry, so that the surface of the paper mold is evenly coated with a layer of ceramic slurry The material is left to stand to make the mold absorb water, and the green body reaches a certain thickness through repeated pouring, and then dried. Send the dried biscuit together with the pape...

Embodiment 3

[0031] The solid ceramic powder is mixed according to mass percentage: fused yttrium oxide stabilized zirconia powder 350 mesh 75%, monoclinic zirconia micropowder 25wt% and fully mixed to make a uniform ceramic powder.

[0032] The solvent is composed of 90% water, 1.5% PVA, 0.2% sodium polyacrylate as a dispersant, and 8.3% water-soluble amino resin.

[0033] The weight ratio of powder and solvent is 85% of powder and 15% of solvent, and a uniform ceramic slurry is made by fully stirring.

[0034] Select a polyurethane resin blister mold, coat a layer of water-absorbing resin film on its surface, pour the mixed ceramic slurry on the surface of the paper mold until the mold is covered with ceramic slurry, let the mold absorb water, and repeat The green body is poured to a certain thickness, and then dried. Send the dried biscuit together with the paper mold into a high-temperature firing furnace for sintering, raise the temperature to 800°C at a certain heating rate, and kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com