Rosin-based flux for ZnSn-based lead free solder and preparation method thereof

A lead-free solder and rosin-based technology, applied in the field of flux in the welding field, can solve the problems of poor wettability and low solid content, and achieve the effect of strong wetting force, low solid content and high insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] At normal temperature, 20g rosin is added into 45g isopropanol and stirred to dissolve, and in another beaker, add 5g organic acid active agent, 1g corrosion inhibitor, 0.1g surfactant and 28.9g isopropanol successively, stir and dissolve The two solutions are mixed, fully stirred and stored at low temperature to obtain 100g of rosin-based flux for ZnSn-based solder;

[0028] Wherein, the composition of organic acid active agent is: 2gL-arginine, 1.5g azelaic acid and 1.5g pimelic acid;

[0029] The composition of the corrosion inhibitor is: 0.5g triethylamine and 0.5g benzotriazole;

[0030] The composition of the surfactant is: 0.05g of OP series surfactants and 0.05g of fluoroaliphatic polyether.

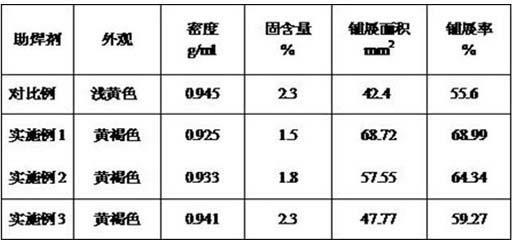

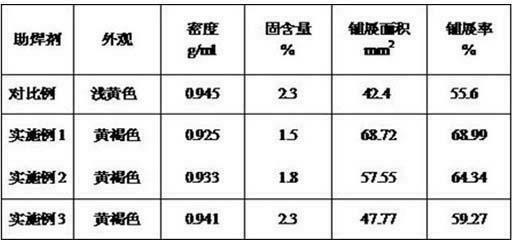

[0031] Compared with the commercially available rosin-based no-clean flux, the density and solid content have decreased by 2.1% and 34.7% respectively, and the spread area and spread rate have increased by 67.1% and 24.1% respectively, so the ZnSn series solder of embodim...

Embodiment 2

[0033] At room temperature, add 40g of rosin to 50g of glycerol and stir to dissolve, then add 1g of organic acid active agent, 0.01g of corrosion inhibitor, 1g of surfactant and 7.99g of glycerin to another beaker, and stir to dissolve Finally, the two solutions are mixed, fully stirred and stored at low temperature to obtain 100g of rosin-based flux for ZnSn-based solder;

[0034] Wherein, the composition of organic acid active agent is: 0.3g succinic acid, 0.4g adipic acid and 0.3g sebacic acid;

[0035] The composition of corrosion inhibitor is: 0.01g triethylamine;

[0036] The composition of the surfactant is: 0.5 g sodium diethyl succinate sulfonate and 0.5 g cetyl trimethyl ammonium bromide.

[0037] Compared with the commercially available rosin-based no-clean flux, the density and solid content have decreased by 1.3% and 21.7% respectively, and the spread area and spread rate have increased by 35.7% and 15.7% respectively, so the ZnSn series solder of embodiment 2 i...

Embodiment 3

[0039] At normal temperature, 30 g of rosin is added to 50 g of ethanol and stirred to dissolve. In another beaker, 3 g of organic acid active agent, 2 g of corrosion inhibitor, 0.5 g of surfactant and 14.5 g of glycerol are added successively. After stirring and dissolving, the The two solutions are mixed, fully stirred and stored at low temperature to obtain 100g of rosin-based flux for ZnSn-based solder;

[0040] Wherein, the composition of organic acid active agent is: 1.5g malic acid and 1.5g succinic acid;

[0041] The corrosion inhibitor consists of: 2g of benzotriazole;

[0042] The composition of the surfactant is: 0.5 g of quaternary ammonium fluoroalkyl compound.

[0043] Compared with the commercially available rosin-based no-cleaning flux, the density and solid content did not change much, and the spreading area and spreading rate increased by 13.7% and 6.6%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com