Preparation method of spinel type lithium manganese oxide for spherical high-voltage anode material

A cathode material, lithium nickel manganese oxide technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low product purity, batch stability particle morphology and size are difficult to control, uneven mixing, etc. The synthesis process is simple, suitable for industrial production, and the uniformity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

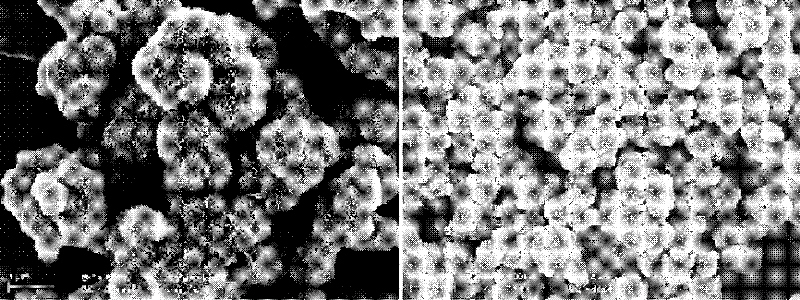

[0028] Take by weighing 4.53g manganese sulfate, 2.106g nickel sulfate, 0.234g cobalt sulfate, add deionized water to be configured into a 1mol / L solution; in addition weigh 5.4g sodium carbonate, dissolve in deionized water to form a 1mol / L solution; then Under the condition of stirring, the sodium carbonate solution was slowly dripped into the solution of the above mixed metal ions, then weighed 0.544g sodium dodecylsulfonate, added it in batches to the above mixed solution, stirred at room temperature for 3 After one hour, after adjusting the pH value to 8, it was transferred to the hydrothermal reaction kettle of 100mL polytetrafluoroethylene, and reacted for 10 hours at 120°C; centrifuged, and the filter cake was washed 5 times with deionized water, and the After drying in air at 100°C for 12 hours, 5.10 g of carbonate precipitates were obtained.

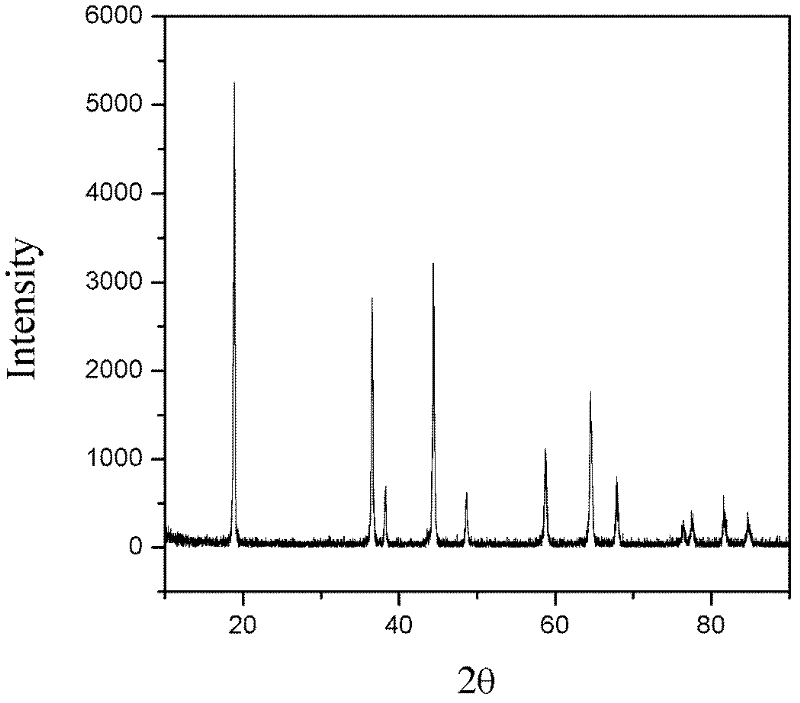

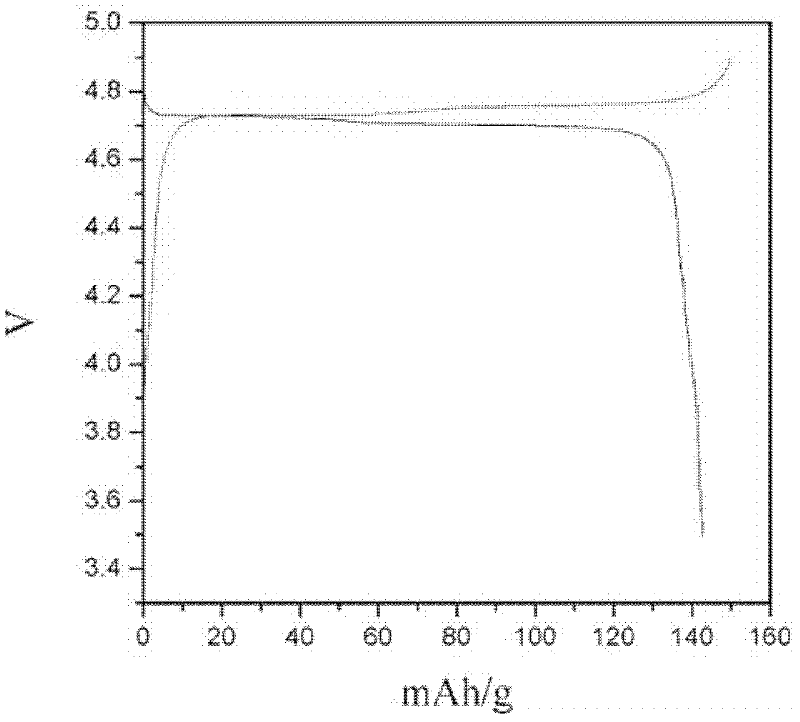

[0029] Weighed 2.22 g of the carbonate precipitate, placed it in an alumina crucible, and fired it in a muffle furnace a...

Embodiment 2

[0032]Take by weighing 5.4g manganese nitrate, 2.43g nickel nitrate, 0.27g cobalt nitrate, add deionized water and be configured to a solution of 1mol / L; take by weighing 5.4g sodium carbonate in addition, be dissolved in deionized water to form a 1mol / L solution; then Under the condition of stirring, the sodium carbonate solution was slowly dripped into the solution of the above mixed metal ions, then weighed 0.544g sodium dodecylsulfonate, added it in batches to the above mixed solution, stirred at room temperature for 3 After one hour, after adjusting the pH value to 8, it was transferred to the hydrothermal reaction kettle of 100mL polytetrafluoroethylene, and reacted for 10 hours at 120°C; centrifuged, and the filter cake was washed 5 times with deionized water, and the After drying in air at 100°C for 12 hours, 5.10 g of carbonate precipitates were obtained.

[0033] Weighed 2.22 g of the carbonate precipitate, placed it in an alumina crucible, and fired it in a muf...

Embodiment 3

[0036] Take by weighing 4.53g manganese sulfate, 2.43g nickel nitrate, 0.234g cobalt sulfate, add deionized water to be configured into a 1mol / L solution; in addition weigh 5.4g sodium carbonate, dissolve in deionized water to form a 1mol / L solution; then Under the condition of stirring, the sodium carbonate solution was slowly dripped into the solution of the above mixed metal ions, then weighed 0.544g sodium dodecylsulfonate, added it in batches to the above mixed solution, stirred at room temperature for 3 After one hour, after adjusting the pH value to 8, it was transferred to the hydrothermal reaction kettle of 100mL polytetrafluoroethylene, and reacted for 10 hours at 120°C; centrifuged, and the filter cake was washed 5 times with deionized water, and the After drying in air at 100°C for 12 hours, 4.89 g of carbonate precipitates were obtained.

[0037] Weighed 2.22 g of the carbonate precipitate, placed it in an alumina crucible, and fired it in a muffle furnace at 400°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com