High-coulombic-efficiency negative electrode active material of carbon-coated lithium-rich lithium titanate of lithium ion battery and preparation method for high-coulombic-efficiency negative electrode active material of carbon-coated lithium-rich lithium titanate

A negative electrode active material, a technology for lithium ion batteries, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as failure of lithium-rich lithium titanate, eliminate the irreversible capacity loss of the first cycle, simple process flow, and easy industrialized production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Lithium source Li 2 CO 3 , titanium source TiO 2 Mix the three raw materials with the carbon source mesophase pitch according to the following addition ratio, and the molar ratio of Li:Ti is 4.5:5. Add Li 2 CO 3 and TiO 2 , the amount of mesophase pitch added is Li 2 CO 3 and TiO 2 3% of the sum of the mass of the two materials; then fully mixed by ball milling, and in an argon atmosphere, the temperature was raised to 850°C for 15 hours; finally cooled to room temperature.

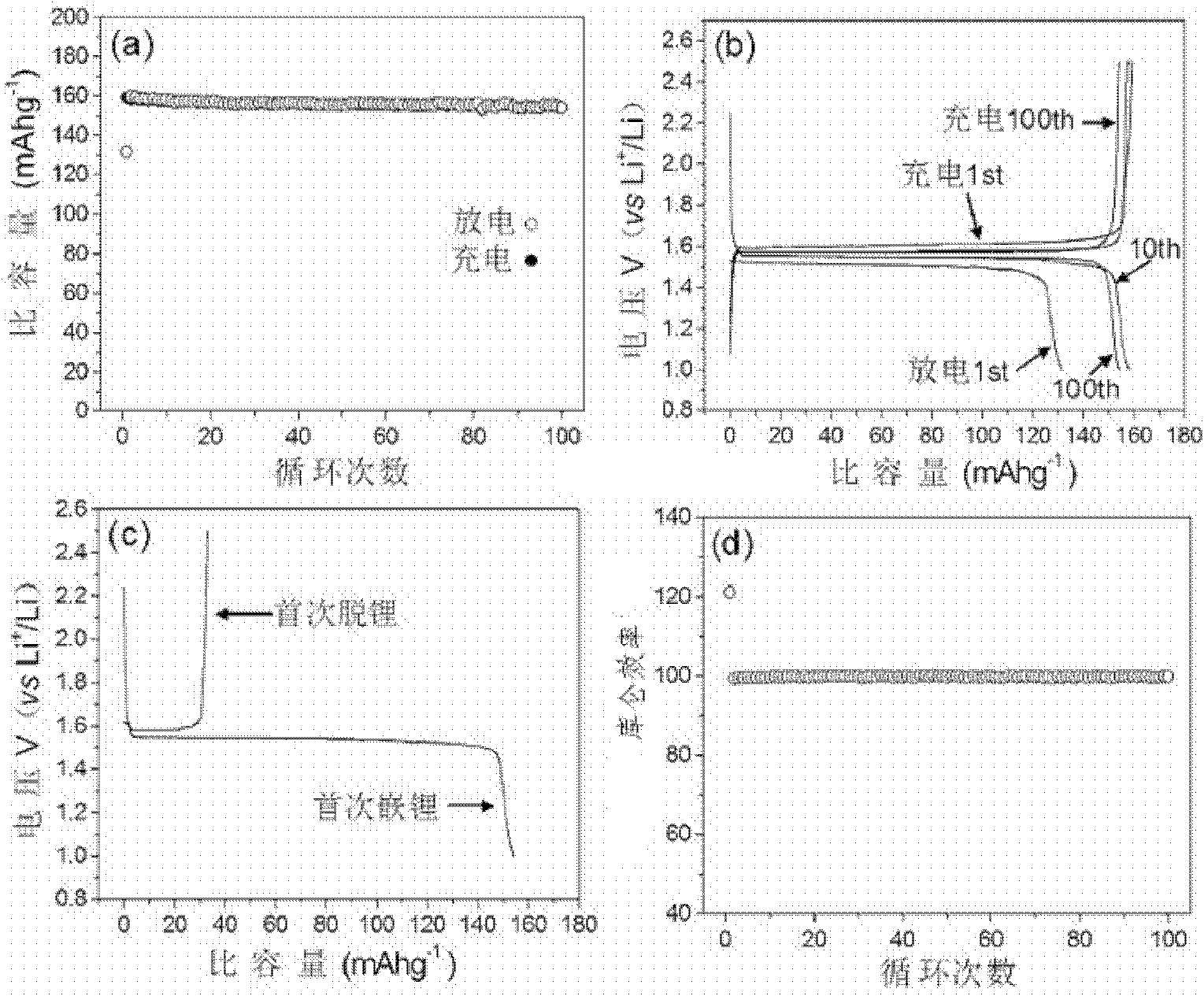

[0019] Carbon-coated Li was prepared by the above method 4+x Ti 5 o 12 Composite powder material, where x is 0.49. Prepare it as a lithium-ion battery negative electrode active material into a lithium-ion button battery, test its electrical properties, the results are as follows figure 1 shown. one of them figure 1 The charge and discharge cycle results of a show that the first charge specific capacity of the battery is 159.3mAhg -1 (delithiation), and the first discharge specific cap...

Embodiment 2

[0021] Lithium source LiOH, titanium source TiO 2 and the three raw materials of carbon source phenolic resin are mixed uniformly according to the following addition ratio, and the molar ratio of Li:Ti is 5:5. Add LiOH and TiO 2 , the amount of phenolic resin added is LiOH and TiO 2 5% of the sum of the mass of the two materials; then thoroughly mixed by ball milling, and then in an argon atmosphere, the temperature was raised to 900°C and kept at the temperature for 12 hours; finally cooled to room temperature.

[0022] Carbon-coated Li was prepared by the above method 4+x Ti 5 o 12 Composite powder material, where x is 0.83. Prepare it as a lithium-ion battery negative electrode active material into a lithium-ion button battery, test its electrical properties, the results are as follows figure 2 shown. one of them figure 2 The charge and discharge cycle results of a show that the first charge specific capacity of the battery is 161.4mAhg -1 (delithiation), and the ...

Embodiment 3

[0024] Lithium source Li 2 CO 3 , titanium source TiO 2 and the carbon source citric acid are ball-milled into powder materials and then mixed uniformly according to the following addition ratio. The molar ratio of Li:Ti is 6:5. 2 CO 3 and TiO 2 , the amount of citric acid added is Li 2 CO 3 50% of the mass; then under a nitrogen atmosphere, the temperature was raised to 800° C. and then kept at a constant temperature for 20 hours; finally cooled to room temperature.

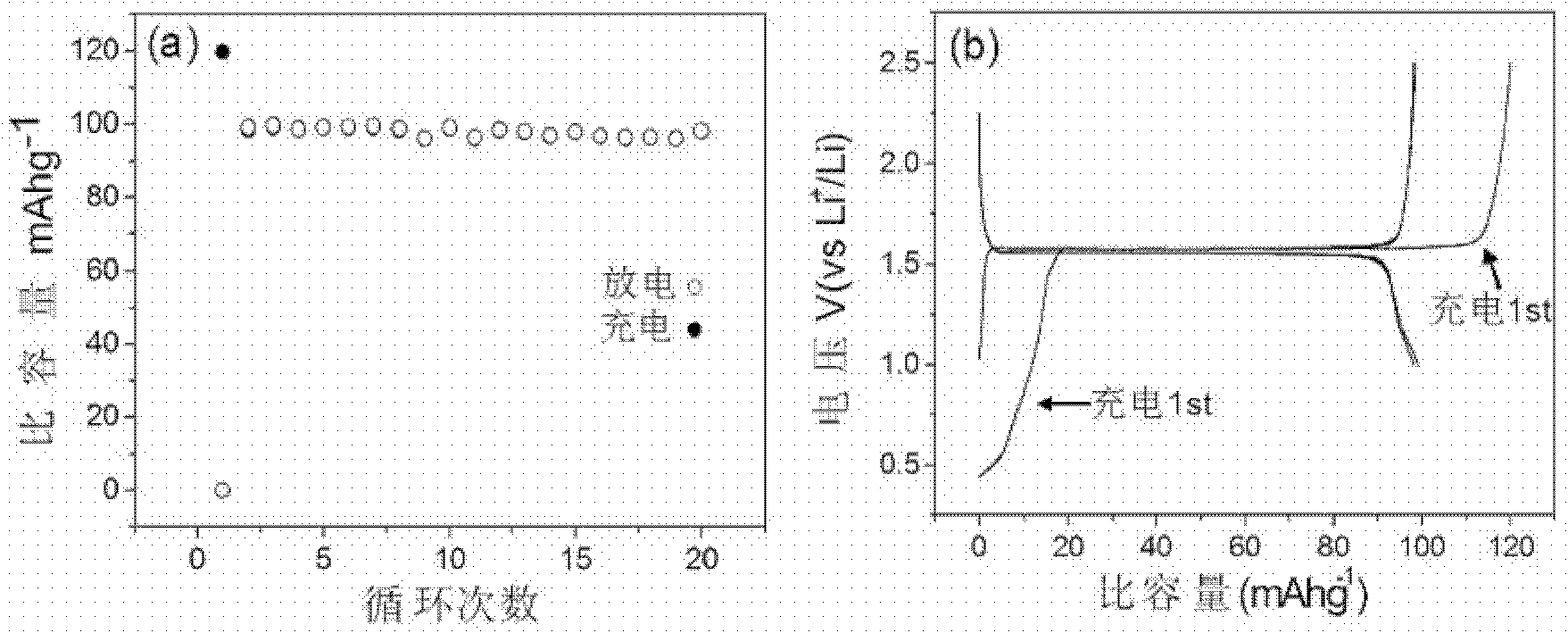

[0025] Carbon-coated Li was prepared by the above method 4+x Ti 5 o 12 Composite powder material, where x is 2.0. Prepare it as a lithium-ion battery negative electrode active material into a lithium-ion button battery, and test its electrochemical performance. The results are as follows: image 3 shown. in image 3 The charge and discharge cycle results of a show that the first discharge specific capacity of the battery is 0mAhg -1 (lithium insertion), and the specific capacity of the first charge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com