Nano silicon film solar battery elliptic polarized light real-time monitoring preparation method

A nano-silicon thin film and solar cell technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of no process repeatability, poor maturity, and low photoelectric conversion efficiency of thin-film solar cells, so as to improve repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

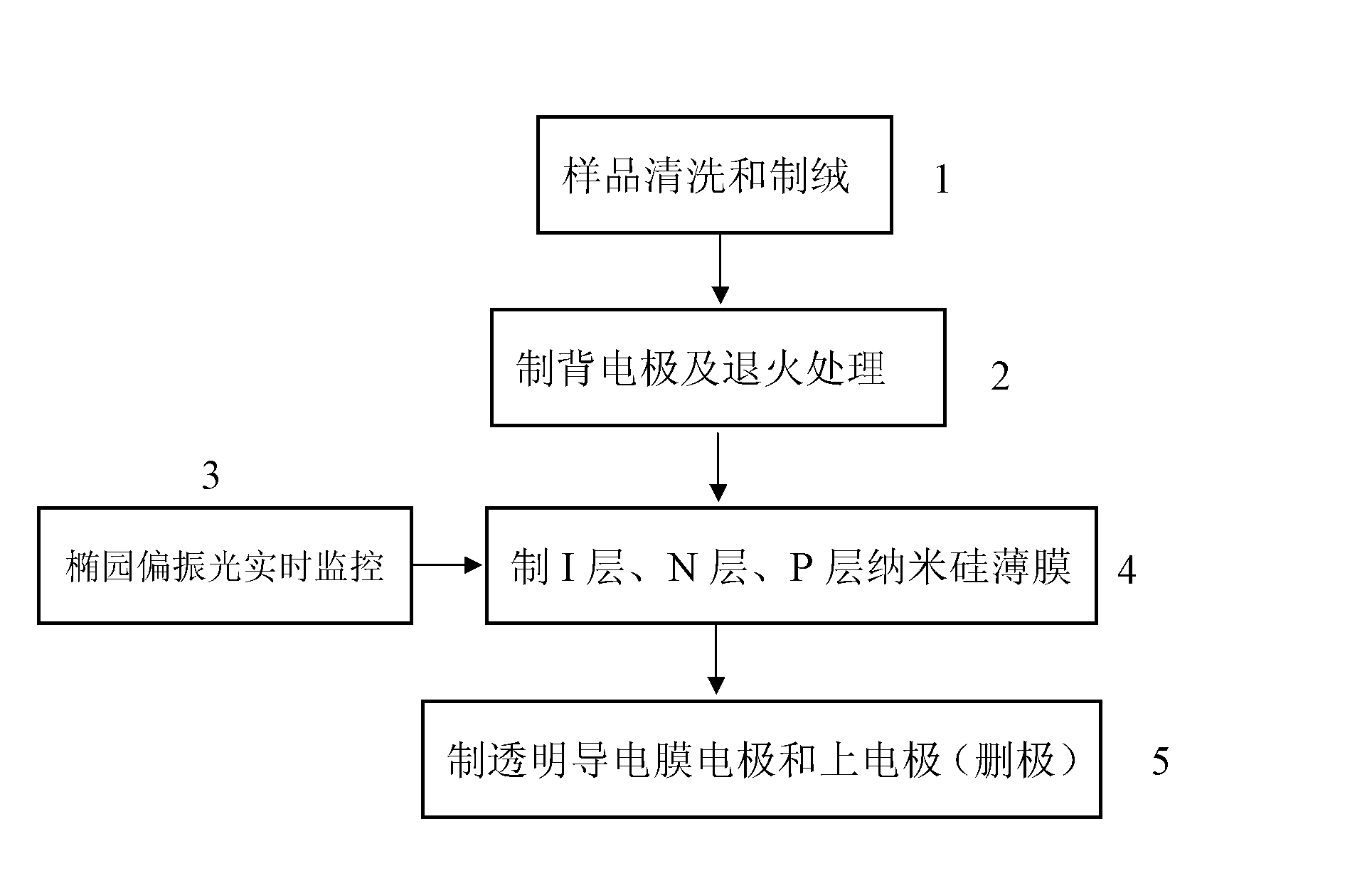

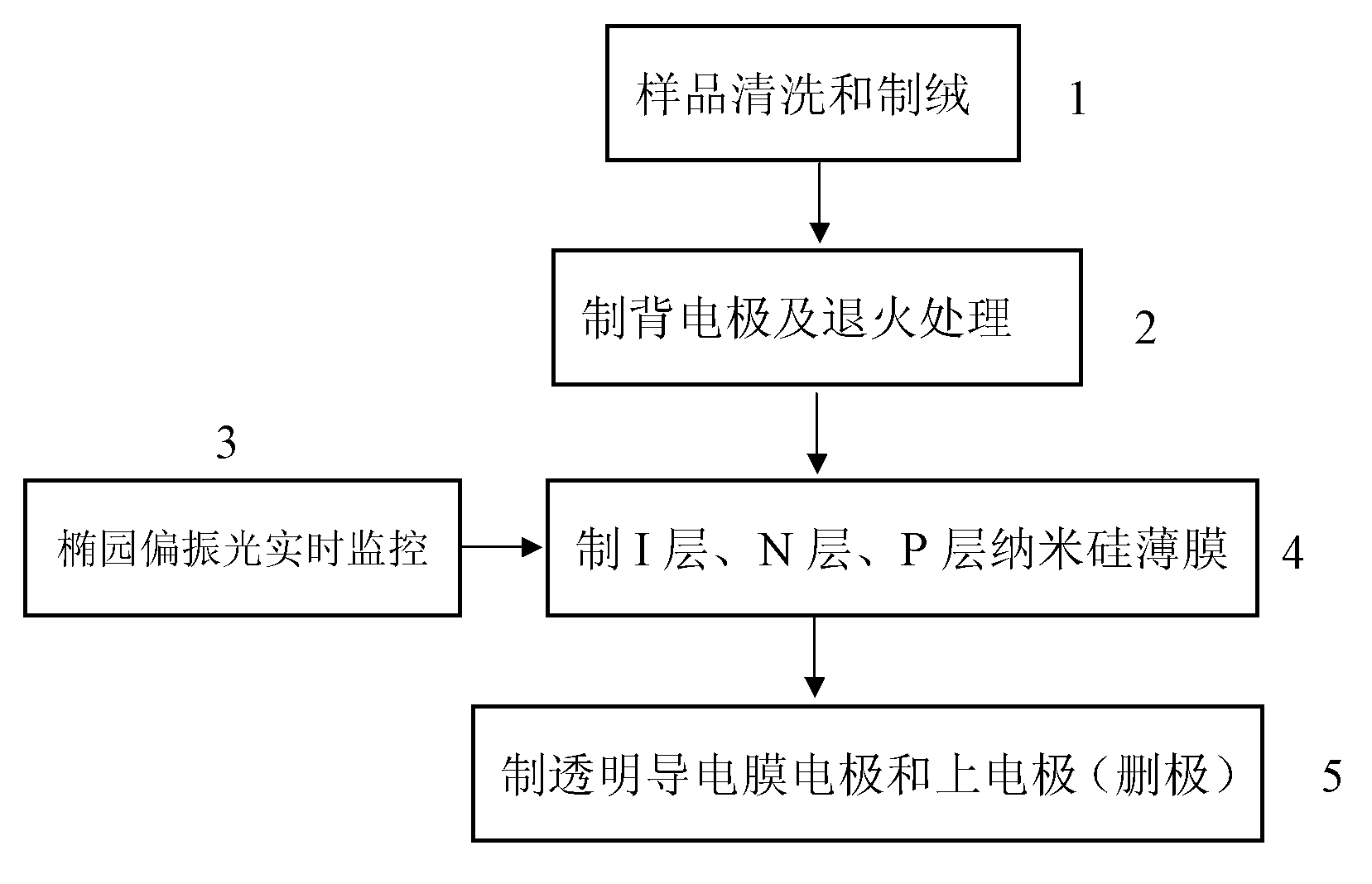

[0033] See figure 1 A preparation method for real-time monitoring of ellipsoidal polarized light of a nano-silicon thin-film solar cell of the present invention, comprising the following steps:

[0034] Step 1: After the P-type silicon wafer is cleaned by the conventional silicon wafer cleaning process, that is, the improved RCA cleaning process, it is placed in a polytetrafluoroethylene container and etched with a dilute solution of HF: deionized water = 1:50 for 10 seconds time, and then rinse the HF acid with a large amount of deionized water within 30 seconds to remove the silicon dioxide layer on the single crystal silicon wafer. The method of chemical etching with alkaline solution is to use NaOH as a reactant and isopropanol as an additive to adjust the anisotropy factor of the corrosion rate. The mixed solution of NaOH and isopropanol is used for anisotropic etching of single crystal silicon. The NaOH concentration is 3 %, the amount of isopropanol is 5%, the reaction...

Embodiment 2

[0040] See figure 1 A preparation method for real-time monitoring of ellipsoidal polarized light of a nano-silicon thin-film solar cell of the present invention, comprising the following steps:

[0041] Step 1: After the N-type silicon wafer is cleaned by the conventional silicon wafer cleaning process, that is, the improved RCA cleaning process, it is placed in a polytetrafluoroethylene container and etched with a dilute solution of HF: deionized water = 1:50 for 10 seconds Then rinse the HF acid with a large amount of deionized water within 30 seconds to remove the silicon dioxide layer on the single crystal silicon wafer. The method of chemical etching with alkaline solution is to use NaOH as a reactant and isopropanol as an additive to adjust the anisotropy factor of the corrosion rate. The mixed solution of NaOH and isopropanol is used for anisotropic etching of single crystal silicon. The NaOH concentration is 3 %, the amount of isopropanol is 5%, the reaction temperatu...

Embodiment 3

[0047] See figure 1 A preparation method for real-time monitoring of ellipsoidal polarized light of a nano-silicon thin-film solar cell of the present invention, comprising the following steps:

[0048] Step 1: After the P-type silicon wafer is cleaned by the conventional silicon wafer cleaning process, that is, the improved RCA cleaning process, it is placed in a polytetrafluoroethylene container and etched with a dilute solution of HF: deionized water = 1:50 for 10 seconds Then rinse the HF acid with a large amount of deionized water within 30 seconds to remove the silicon dioxide layer on the single crystal silicon wafer. The method of chemical etching with alkaline solution is to use NaOH as a reactant and isopropanol as an additive to adjust the anisotropy factor of the corrosion rate. The mixed solution of NaOH and isopropanol is used for anisotropic etching of single crystal silicon. The NaOH concentration is 3 %, the amount of isopropanol is 5%, the reaction temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com