Blue rare earth zirconium ceramic powder as well as manufacture and application thereof

A technology of ceramic powder and rare earth, applied in the field of ceramic materials, can solve the problems of low anti-aging performance, reduced material toughness, strength and hardness, flexural strength, fracture toughness, etc., to enrich the market and improve the quality of life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

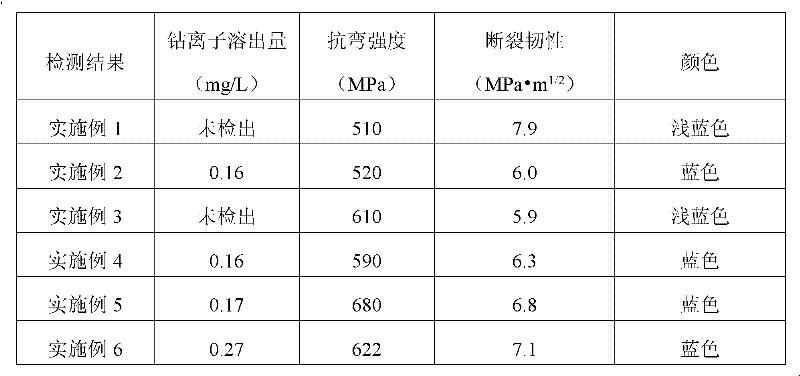

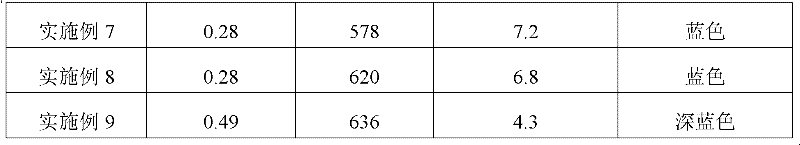

[0035] Embodiment 1~9 batching according to the table:

[0036] Table 1 Example ingredient list (unit: kg)

[0037] Example

[0038] La 2 o 3

Embodiment 1

[0040] CoAl 2 o 4 and rare earth oxides as raw materials to prepare blue rare earth zirconium structure ceramic powder and blue rare earth zirconium ceramic knife blank.

[0041] Step 1: CoAl is mixed according to the proportioning of embodiment 1 in table 1 2 o 4 And each rare earth oxide and 80kg of deionized water are added into a ball mill and ball milled to become D 50 = 0.48 μm slurry one [slurry particle size data is measured by "Easizer 30" wet method, the following examples are the same].

[0042] Step 2: Add 16.7kg of PVA and 1.1kg of CMC to slurry 1 and continue ball milling to obtain slurry 2;

[0043] Step 3: Input the slurry 2 into the spray granulator for spray granulation to obtain particle size D 25 =8.7μm, D 50 = 10.3 μm, D 75 =20.6μm, (D 75 -D 25 ) / (D 75 +D 25 )=0.41 blue rare earth zirconium granulated powder (the particle size data of the powdery material is measured by a German Sympate automatic laser particle size analyzer, and the following e...

Embodiment 2

[0046] CoAl 2 o 4 Prepare blue rare earth zirconium ceramic powder and blue rare earth zirconium ceramic knife blank with yttrium zirconium ceramic powder and other oxides as raw materials:

[0047] Step 1: 89.7kg of yttrium-zirconium ceramic granulated powder (calculated as Y in terms of oxides) 2 o 3 3.46wt%, ZrO 2 96.54wt%), CoAl in Table 1 Example 2 2 o 4 and divide Y 2 o 3 , ZrO 2 Add other oxides and deionized water 90kg into ball mill and ball mill to become D 50 = 0.53 μm slurry one; the yttrium-zirconium ceramic granulated powder is a mixture of yttrium oxide and zirconium oxide obtained by burning yttrium-zirconium hydroxide and then pulverized and spray-granulated powder (without granulation It is called yttrium zirconium jet powder).

[0048] Step 2: Add 12.5kg of PVA and 1.05kg of CMC to slurry 1 and continue ball milling to obtain slurry 2;

[0049] Step 3: Input the slurry 2 into the spray granulator for spray granulation to obtain D 25 =11.8μm, part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com