Method for manufacturing ceiling

A production method and ceiling technology, applied in the direction of chemical instruments and methods, natural mineral layered products, layered products, etc., can solve the problems of low hardness, insufficient adhesion, and short service life, etc., to achieve extended use Long life, moisture-proof and sound insulation effect, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

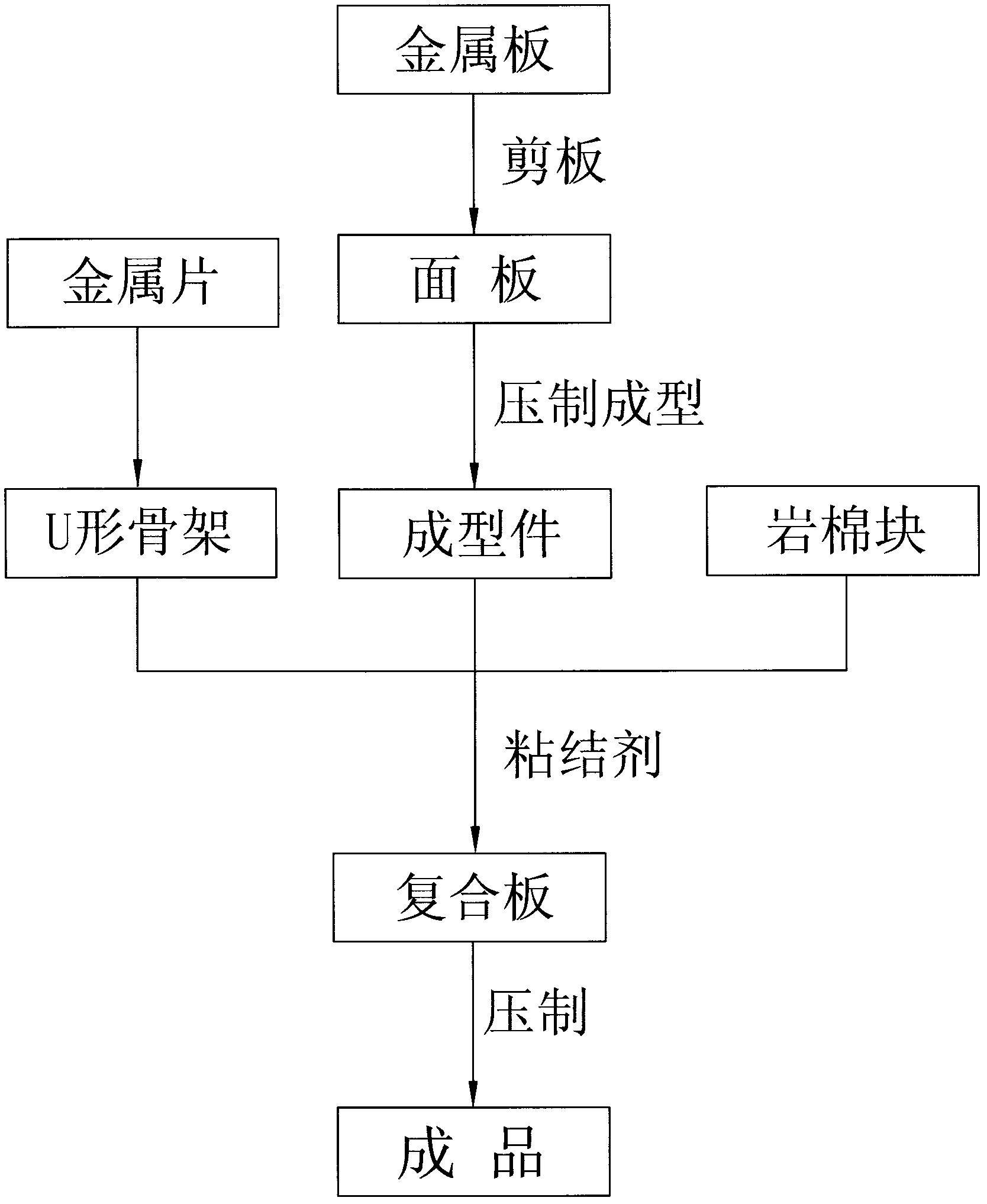

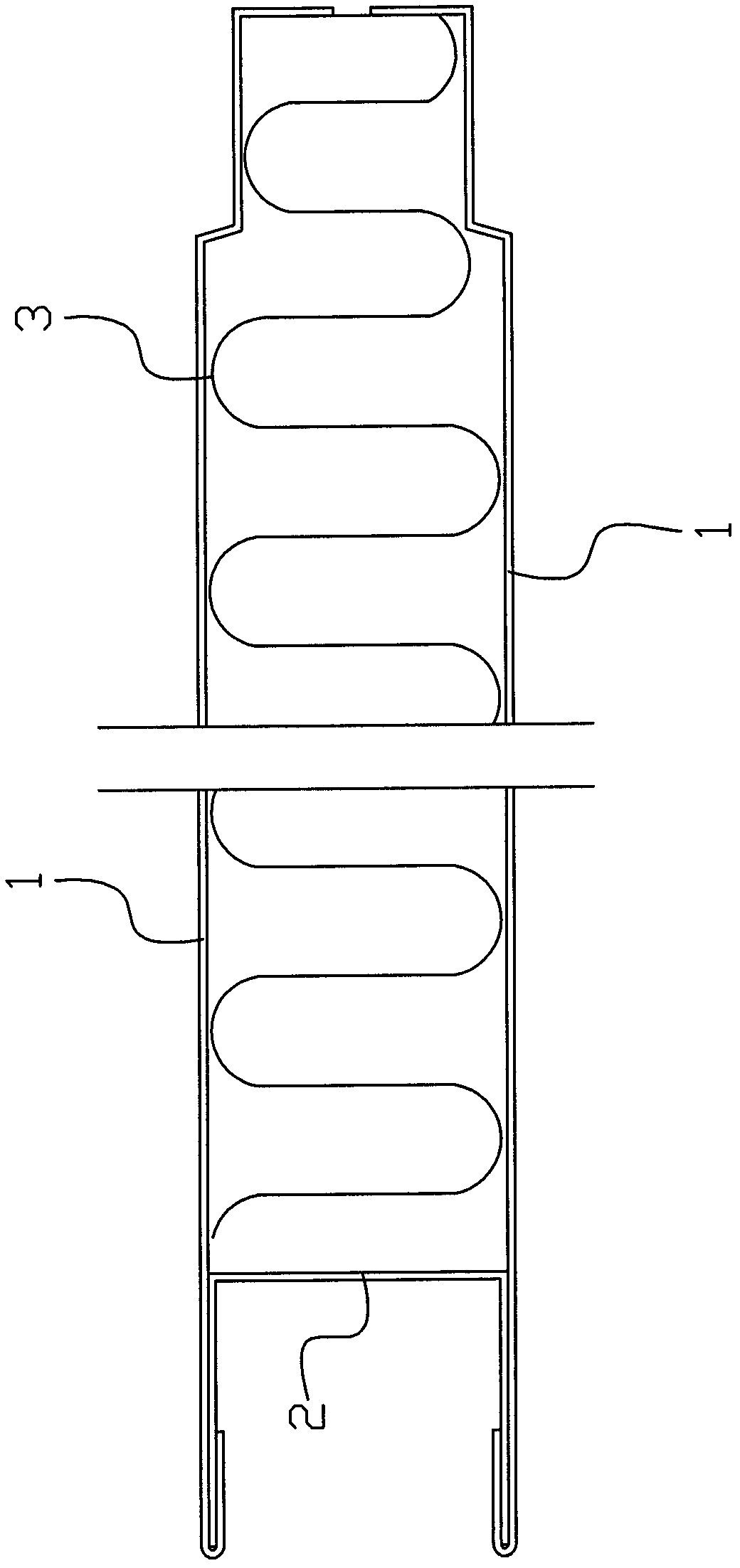

[0030] Embodiment one: if Figure 1 to Figure 3 Shown, the manufacture method of this ceiling comprises the following steps:

[0031] 1. Cut the metal plate 1 into required specifications and sizes; the metal plate 1 in this embodiment is preferably a plastic-coated steel plate or a galvanized plate

[0032] 2. Place the cut plastic-coated steel sheet or galvanized sheet in a rolling mill to press and form it to become a formed part;

[0033] 3. Fold the iron sheet into a U-shape to form a U-shaped skeleton 2 for use;

[0034] 4. Cut the rock wool block 3 into the desired shape and thickness, and set aside;

[0035] 5. Insert the spare U-shaped skeleton 2 into the notch curling of the molded part, then evenly apply the adhesive on the molded part, and then spread the cut rock wool block 3 on the molded part coated with adhesive , and then another molded piece coated with adhesive is covered on the laid rock wool block 3 to form a composite board; the binder is a polymer con...

Embodiment 2

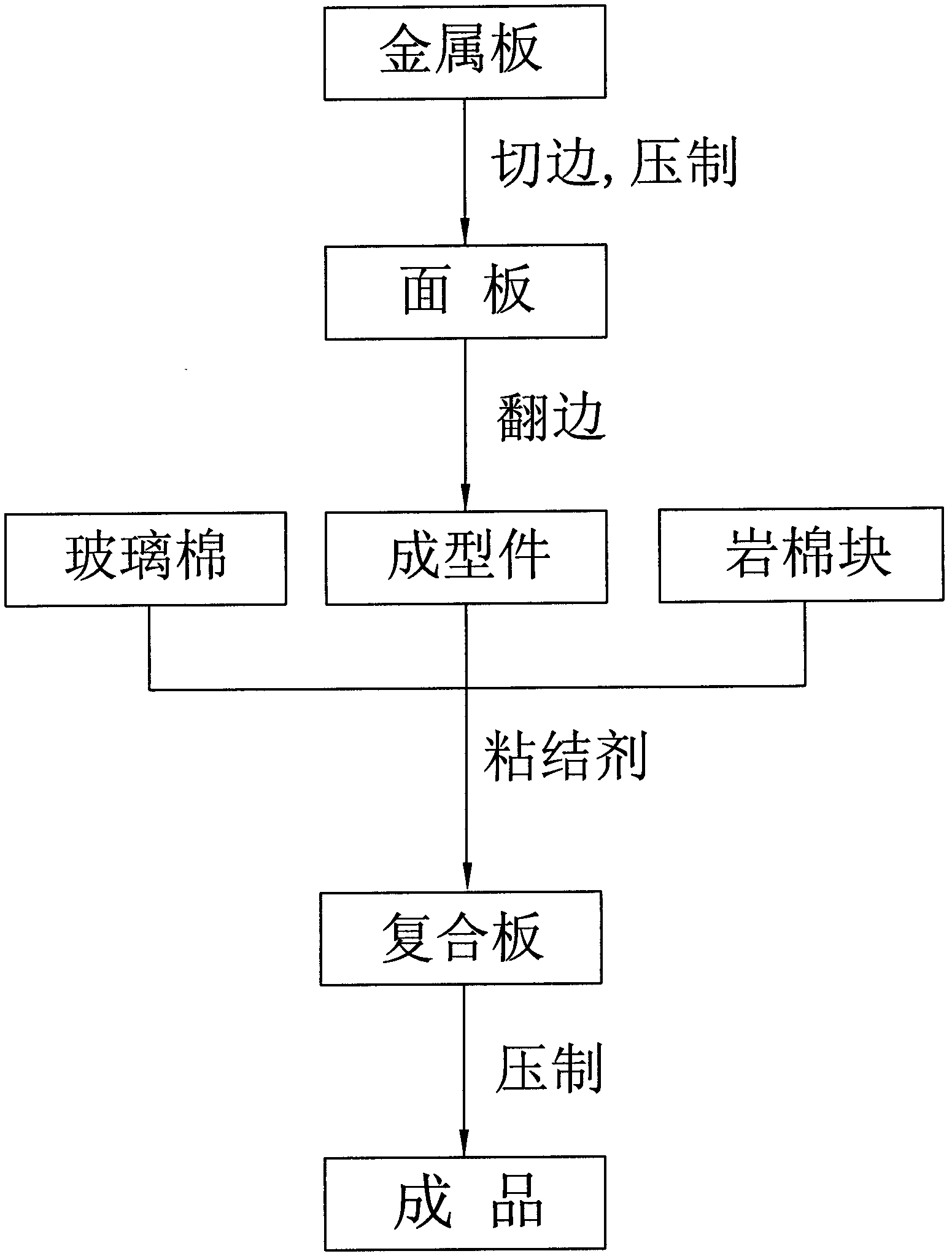

[0037] Embodiment two: if Figure 1 to Figure 3 Shown, the manufacture method of this ceiling comprises the following steps:

[0038] 1. Cut the plastic-coated steel sheet or galvanized sheet into the required size;

[0039] 2. Place the cut plastic-coated steel sheet or galvanized sheet in a rolling mill to press and form it to become a formed part;

[0040] 3. Place the formed part in the flanging mold for flanging, flanging to the required height, and set aside;

[0041] 4. Cut the rock wool block 3 into the desired shape and thickness for later use; the density of the rock wool block 3 is 120-150kg / m;

[0042] 5. Apply adhesive evenly on the molded part, and spread the prepared rock wool block 3 on the molded part coated with adhesive to form a composite board; the composite board is also filled with insulating materials.

[0043] 6. Next, place the composite board in a pressing mold and press it, so that the rock wool block 3 is firmly combined with the molded part thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com