Sleeve forging and pressing preparation method of bismuth-telluride-base thermoelectric material

A thermoelectric material, bismuth telluride-based technology, applied in the field of new preparation of bismuth telluride-based thermoelectric materials, can solve the problems of long preparation process, complicated equipment, high energy consumption, etc., and achieve simple preparation process, simple equipment and low preparation cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

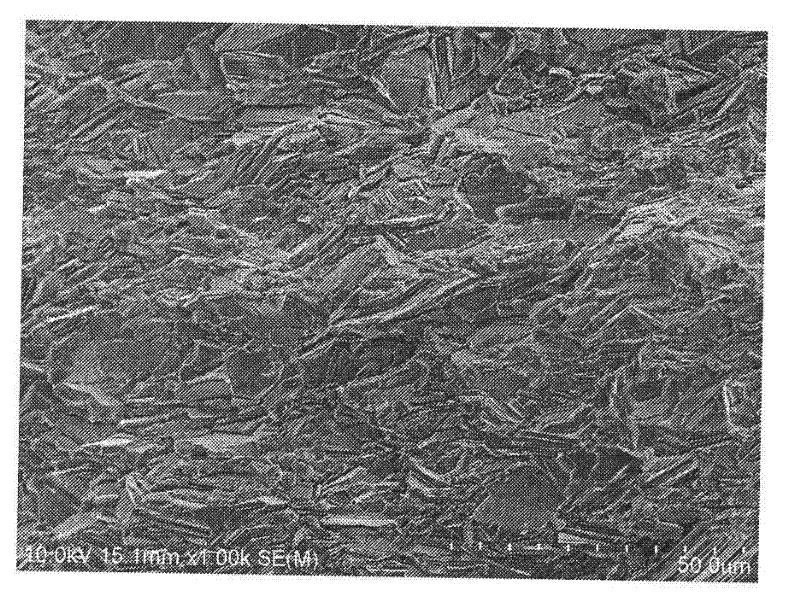

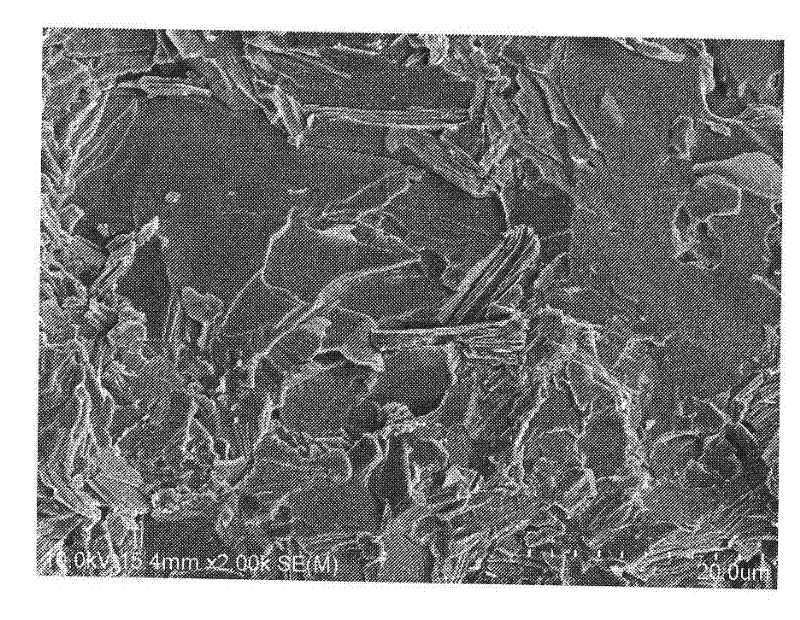

Embodiment 1

[0033]Get 30g of commercial P-type bismuth telluride bars prepared by zone melting method (same as reference example 1), pulverize and grind into powder less than 200 meshes, and then put the powder into an aluminum casing with an outer diameter of Φ22mm and a wall thickness of 3mm. The tube is then placed in a cold die, and the powder is compacted into a block billet with a press, and then the excess aluminum sleeve that is higher than the sample is removed so that the aluminum sleeve is flush with the upper and lower edges of the sample. Then place the sample with the aluminum sleeve in a Φ26mm hot forging steel mold, place the sample together with the hot forging steel mold in an annular heating mantle on the operating table of the hydraulic press, heat the sample to 450°C, and heat-preserve and sinter for 20 minutes. No pressure is applied during the process, and argon gas is introduced into the mold to prevent the sample from being oxidized during the heat preservation and...

Embodiment 2

[0035] Take 30g of commercial N-type bismuth telluride bar material prepared by zone melting method (same as reference example 2), crush and grind it into 200 mesh powder as raw material, the following preparation method and parameters are the same as in Example 1. The ZT of the sample at 300K is 0.84, which is 20% higher than that of the sample of reference example 2.

Embodiment 3

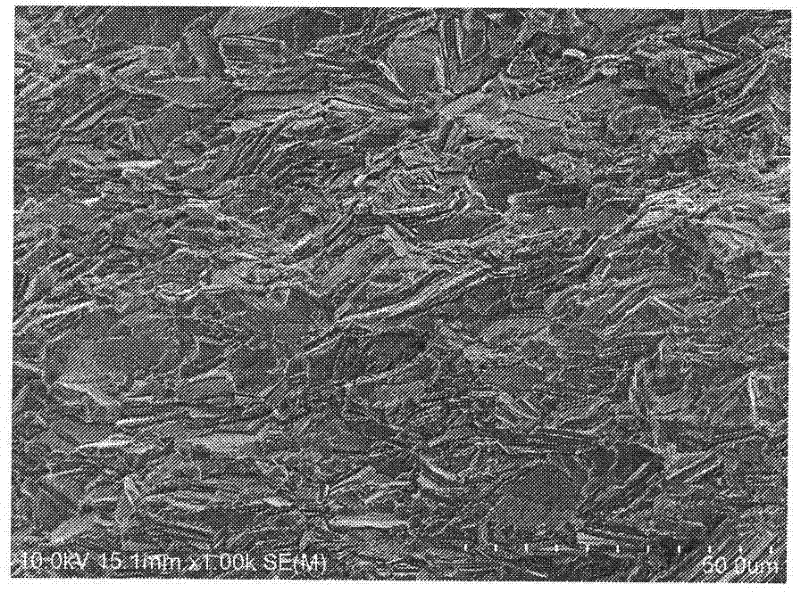

[0037] Choose high-purity elemental bismuth, antimony, and tellurium, according to Bi 0.5 Sb 1.5 Te 3 Weigh the raw material, then melt it in a vacuum induction melting furnace by induction melting, cool down to obtain a bismuth telluride-based alloy (see reference example 3), and then pulverize and grind it into a powder of less than 200 meshes as a raw material. The following preparation method and parameters are the same as in Example 1. The ZT of the sample at 300K is 1.15, which is 67% higher than that of the sample of Reference Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com