High-strength durable type rotational-molded automobile urea box

A urea tank, durable technology, applied in the field of automotive urea tank materials, can solve the problems of not being able to adapt to the conditions of urea tank molding and use, poor long-term aging resistance of polyethylene, poor UV resistance, etc., to achieve long-term aging Good performance and light, simple and easy preparation method, and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0013] The present invention makes the required material of urea tank masterbatch and consists of:

[0014] Linear Low Density Polyethylene (LLDPE) 20 High Density Polyethylene (HDPE) 30

[0015] POE 50 Calcium stearate 1~2 Antioxidant 1010 2~3

[0016] Antioxidant 168 4~6 Antistatic agent---------Hydroxyethylalkylamine 3-8;

[0017] The parts by weight of the materials needed to make the urea tank consist of:

[0018] Masterbatch 8-10 Linear low-density polyethylene 90-92. The masterbatch and LLDPE are mixed in this ratio, avoiding the re-pelletization of all the materials in the twin-screw extruder, causing unnecessary degradation of the material.

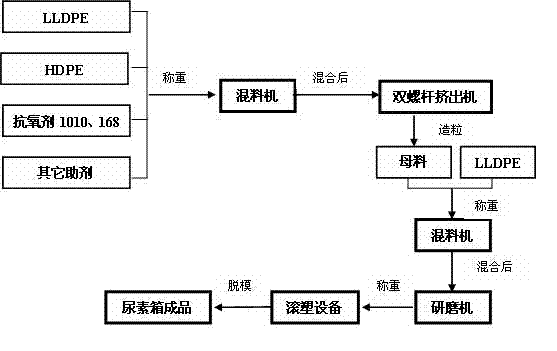

[0019] Weigh linear low-density polyethylene, high-density polyethylene, POE, calcium stearate, antioxidant 1010, antioxidant 168, negative ion powder and antistatic agent according to the proportion, and the antistatic agent adopts hydroxyethyl alkanes base amine; after weighing, put linear low-density polyethylene, high-den...

Embodiment 1

[0021] Linear Low Density Polyethylene (LLDPE) 20 High Density Polyethylene (HDPE) 30

[0022] POE 50 Calcium stearate 1 Antioxidant 1010 2

[0023] Antioxidant 168 4 Antistatic agent---------hydroxyethyl alkylamine 3;

[0024] The parts by weight of the materials needed to make the urea tank consist of:

[0025] Masterbatch 10 Linear Low Density Polyethylene 90. The masterbatch and LLDPE are mixed in this ratio, avoiding the re-pelletization of all the materials in the twin-screw extruder, causing unnecessary degradation of the material.

[0026] Weigh linear low-density polyethylene, high-density polyethylene, POE, calcium stearate, antioxidant 1010, antioxidant 168, negative ion powder and antistatic agent according to the proportion, and the antistatic agent adopts hydroxyethyl alkanes base amine; after weighing, put linear low-density polyethylene, high-density polyethylene, POE, calcium stearate, antioxidant 1010, antioxidant 168, negative ion powder and antistatic ag...

Embodiment 2

[0028] Linear Low Density Polyethylene (LLDPE) 20 High Density Polyethylene (HDPE) 30

[0029] POE 50 Calcium stearate 1 Antioxidant 1010 2

[0030] Antioxidant 168 4 Antistatic agent---------hydroxyethyl alkylamine 3;

[0031] The parts by weight of the materials needed to make the urea tank consist of:

[0032] Masterbatch 9 Linear Low Density Polyethylene 91. The masterbatch and LLDPE are mixed in this ratio, avoiding the re-pelletization of all the materials in the twin-screw extruder, causing unnecessary degradation of the material.

[0033] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com