Method for preparing Roflumilast raw material and intermediates

A technology of roflumilast and intermediates, which is applied in the field of preparation of roflumilast raw materials and intermediates, can solve problems such as low yield, difficult storage and use, and greenhouse effect, and achieve high product yield and low production cost. Low, well-conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

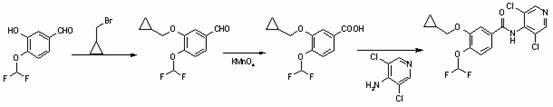

[0025] Embodiment 1: a kind of preparation method of roflumilast raw material and intermediate, comprises the following steps:

[0026] 1. Preparation of 4-difluoromethoxy-3-cyclopropylmethoxybenzaldehyde (intermediate Ⅰ)

[0027]

[0028] Add 1000ml of N,N-dimethylformamide into the three-necked flask, add 350g of 4-difluoromethoxy-3-hydroxybenzaldehyde, 200ml of bromomethylcyclopropane, 350g of anhydrous potassium carbonate, Potassium iodide 140g, stirred and reacted for 6 hours, added 2000ml of water and 1000ml of ethyl acetate, stirred and separated, the aqueous phase was extracted once with 200ml of ethyl acetate, the organic phase was combined, dried with anhydrous sodium sulfate, filtered, and the filtrate was depressurized to recover ethyl acetate Ester to dryness, the obtained 423g oily substance is intermediate I, the yield of this process is 94%, and the HPLC purity is 99.7%.

[0029] 2. Preparation of 4-difluoromethoxy-3-cyclopropylmethoxybenzoic acid (intermed...

Embodiment 2

[0037] Embodiment 2: a kind of preparation method of roflumilast raw material and intermediate, comprises the following steps:

[0038] 1. Preparation of 4-difluoromethoxy-3-cyclopropylmethoxybenzaldehyde (intermediate Ⅰ)

[0039]

[0040] Add 1000ml of N,N-dimethylformamide into the three-necked flask, add 300g of 4-difluoromethoxy-3-hydroxybenzaldehyde, 150ml of bromomethylcyclopropane, 220g of anhydrous potassium carbonate, Potassium iodide 120g, stirred and reacted for 3 hours, added 2000ml of water and 1000ml of ethyl acetate, stirred and separated, the water phase was extracted once with 200ml of ethyl acetate, the organic phase was combined, dried with anhydrous sodium sulfate, filtered, and the filtrate was depressurized to recover ethyl acetate Ester to dryness, the obtained 347g oily substance is Intermediate I, the yield of this process is 90%, and the HPLC purity is 98.6%.

[0041] 2. Preparation of 4-difluoromethoxy-3-cyclopropylmethoxybenzoic acid (intermedia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com