Preparation process of nickel-based supported catalyst and prepared catalyst

A technology of supported catalyst and preparation process, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. It can solve the problem of easy agglomeration of ultrafine powder and collapse of pore structure , Poor mechanical strength of infertile oxides, etc., to achieve the effects of mass and heat transfer, high thermal stability, and low hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

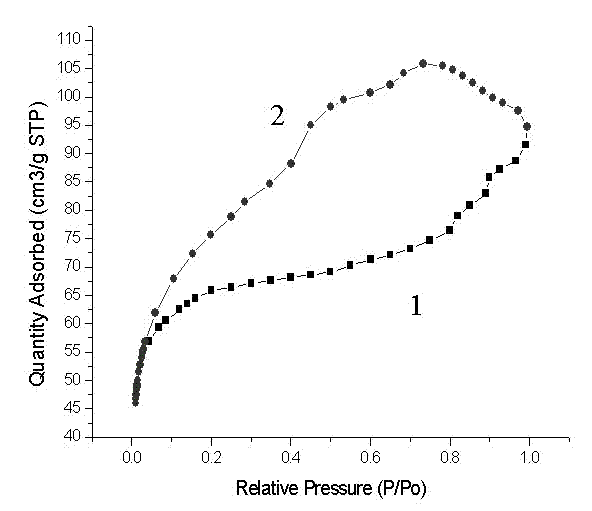

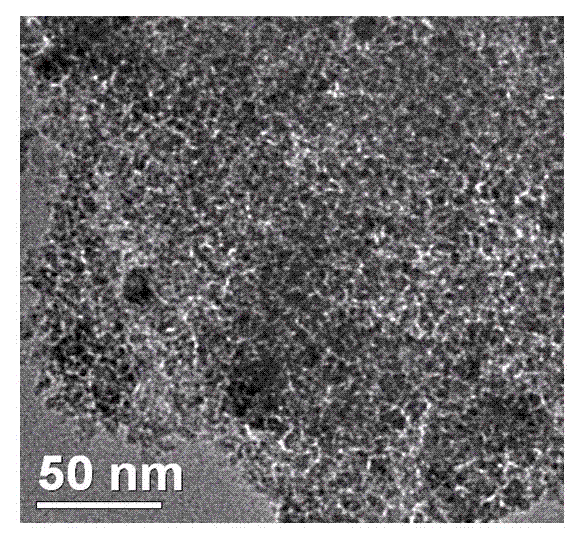

[0057] Commercially available ethyl orthosilicate, silica sol, butyl titanate and nickel nitrate are used as raw materials. First, take 185.8 grams of ethyl orthosilicate and 51.1 grams of butyl titanate in a beaker, add deionized water and absolute ethanol, and prepare 0.22m% (based on TiO 2 -SiO 2 Calculation) TiO 2 -SiO 2 Sol A 1 , 40 ℃ ~ 70 ℃ stirring for 4 hours. Dissolve 70 grams of nickel nitrate in deionized water and absolute ethanol, stir evenly, add 80 grams of silica sol, and prepare Sol B 1 , Sol B 1 The concentration of nickel nitrate in the medium is 11m% (calculated as NiO). Sol B is then 1 Added dropwise to Sol A 1 , to obtain sol C 1 , and continued to stir at a temperature of 40° C. to 70° C. for about 3 hours to obtain a viscous green transparent wet gel with poor fluidity. After the wet gel is dried, a dry bulk catalyst precursor (chemical composition of NiO-TiO 2 -SiO 2 ternary composite oxide).

Embodiment 2~3

[0059] According to Table 2, the dosages of tetraethyl orthosilicate and silica sol were changed, and the rest of the operation steps were the same as in Example 1 to obtain different bulk precursors.

[0060]

Embodiment 4

[0069] Embodiment 4: with NiO-TiO 2 -SiO 2 Extrusion of sol as gelling agent

[0070] 100 grams of the catalyst precursor prepared by the same formula ratio and method as in Example 1 (based on the total weight of the contained oxides), ball milled to a powder of 250 to 350 meshes, and the coating 4 viscometer prepared in Example 1 measured a viscosity of 15 Sol C for ~20 sec 1 (NiO-TiO 2 -SiO 2 sol) 20 grams as a binder, powder-to-glue ratio (mass ratio) = 8: 1, the sol C 1 Add to the powder, then add 6 grams of pore structure modifier polyethylene glycol methyl ether, 1.3 grams of citric acid, knead, and extrude to obtain a cylindrical bar with a diameter of 3 mm. The formed strip-shaped catalyst precursor is dried at 25-150° C. and calcined at 550° C. for 6 hours. The strength and specific surface properties of strip-shaped catalysts (catalyst length 5 mm, 50-80 grains) and specific surface properties are measured, and the data are listed in Table 3. The determina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com