Preparation method of multi-core MgB2 superconducting wire

A technology of superconducting wires and wires, applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., can solve the problems that it is difficult to significantly increase the critical current density of wires, achieve good chemical inertia, improve Connectivity, the effect of strengthening connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

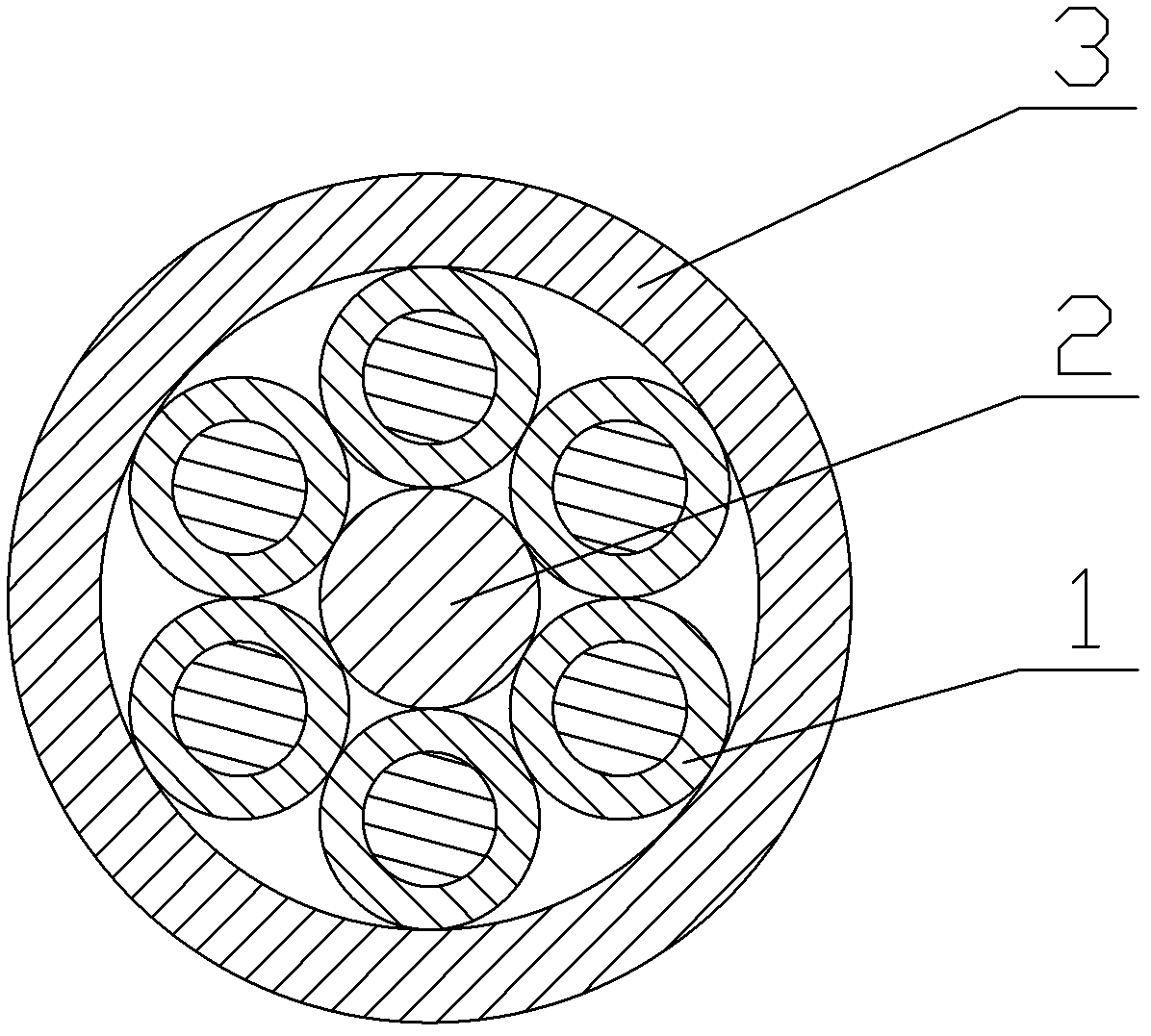

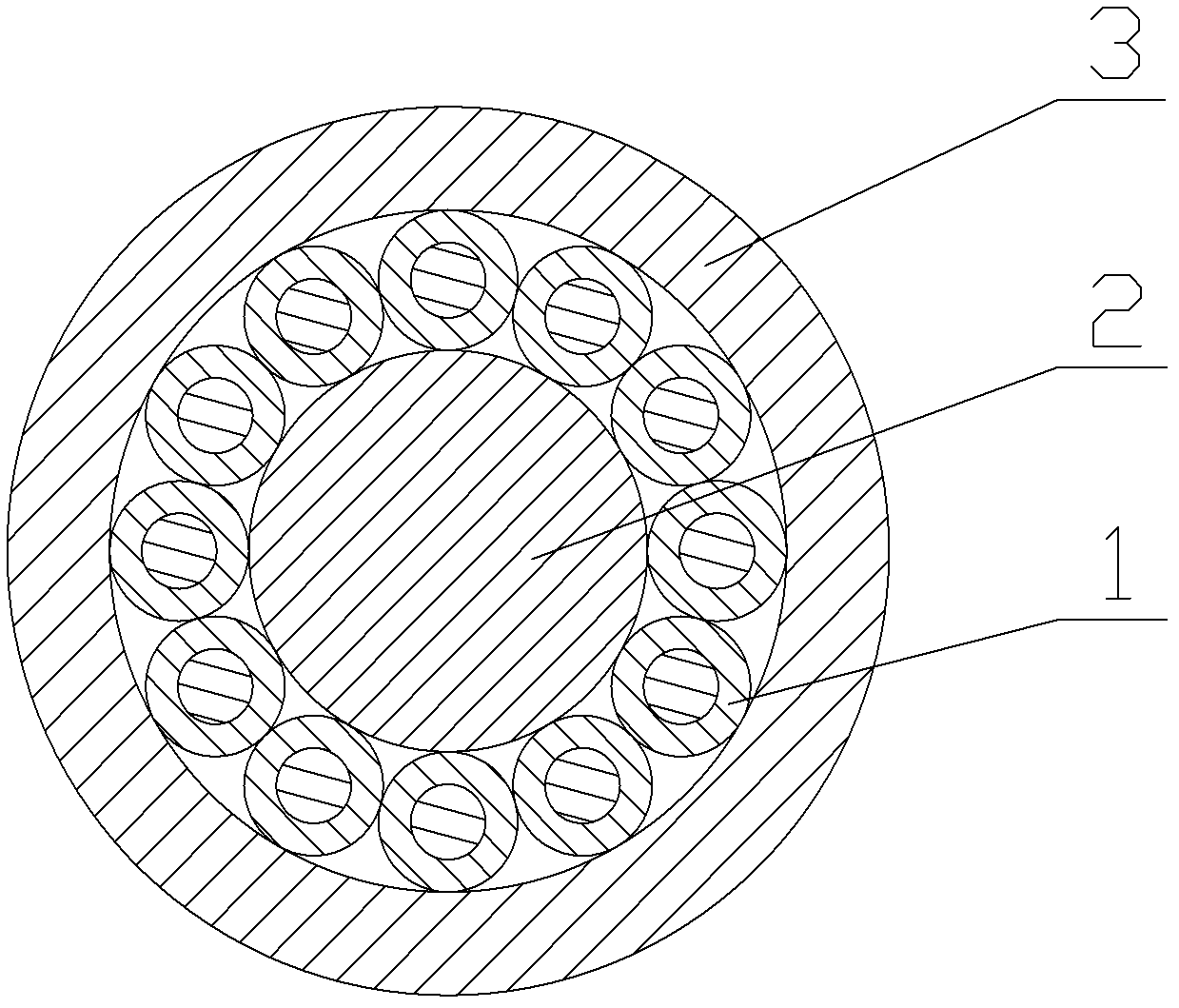

[0030] 7-core MgB 2 Preparation of superconducting wires:

[0031] Step 1, magnesium powder (particle size is-200 mesh, mass purity is 99.8%), amorphous boron powder (mass purity is 99.999%) and nanometer TiC powder (mass purity is 99%) according to Mg:B:TiC= The atomic ratio of 1:1.98:0.02 is mixed, and then the mixture is ground and mixed evenly under the protection of argon to obtain the precursor powder;

[0032] Step 2. Put the precursor powder described in step 1 into the Ta tube (10mm in outer diameter, 1.0mm in wall thickness, and the mass content of Ta is not less than 99.9%) after pickling by conventional methods, and then put the precursor powder Put the powdered Ta tube into an oxygen-free copper tube (with an outer diameter of 12.5 mm, a wall thickness of 1.0 mm, and a residual resistivity of not less than 80) after pickling in a conventional method to obtain a tube-packing complex;

[0033] Step 3. Pass-rolling the tube-loading complex described in step 2 with ...

Embodiment 2

[0039] 7-core MgB 2 Preparation of superconducting wires:

[0040] Step 1, magnesium powder (particle size is-200 mesh, mass purity is 99.8%), amorphous boron powder (mass purity is 99.999%) and nanometer TiC powder (mass purity is 99%) according to Mg:B:TiC= The atomic ratio of 1:1.9:0.1 is mixed, and then the mixture is ground and mixed evenly under the protection of argon to obtain the precursor powder;

[0041] Step 2. Put the precursor powder described in step 1 into the Ta tube (outer diameter is 12mm, wall thickness is 1.5mm, and the mass content of Ta is not less than 99.9%) after pickling by conventional method, and then put the precursor powder Put the powdered Ta tube into an oxygen-free copper tube (with an outer diameter of 15.5 mm, a wall thickness of 1.5 mm, and a residual resistivity of not less than 80) after pickling in a conventional method to obtain a tube-packing complex;

[0042] Step 3: Carry out pass rolling on the tube-loading composite body describe...

Embodiment 3

[0048] 7-core MgB 2 Preparation of superconducting wires:

[0049] Step 1, magnesium powder (particle size is-200 mesh, mass purity is 99.8%), amorphous boron powder (mass purity is 99.999%) and nanometer TiC powder (mass purity is 99%) according to Mg:B:TiC= The atomic ratio of 1:1.95:0.05 is mixed, and then the mixture is ground and mixed evenly under the protection of argon to obtain the precursor powder;

[0050] Step 2. Put the precursor powder described in step 1 into the Ta tube (outer diameter is 11 mm, wall thickness is 1.2 mm, and the mass content of Ta is not less than 99.9%) after pickling by conventional method, and then put the precursor powder The powdered Ta tube is packed into an oxygen-free copper tube (with an outer diameter of 14mm, a wall thickness of 1.2mm, and a residual resistivity of not less than 80) after pickling in a conventional method to obtain a tube-packing complex;

[0051] Step 3. Pass-rolling the tube-loading complex described in step 2 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com