Method for preparing section sample used for analyzing evolution process of cubic texture

An evolutionary, cubic texture technology, applied in the preparation of test samples, material analysis using measurement of secondary emissions, material analysis using wave/particle radiation, etc. Less texture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

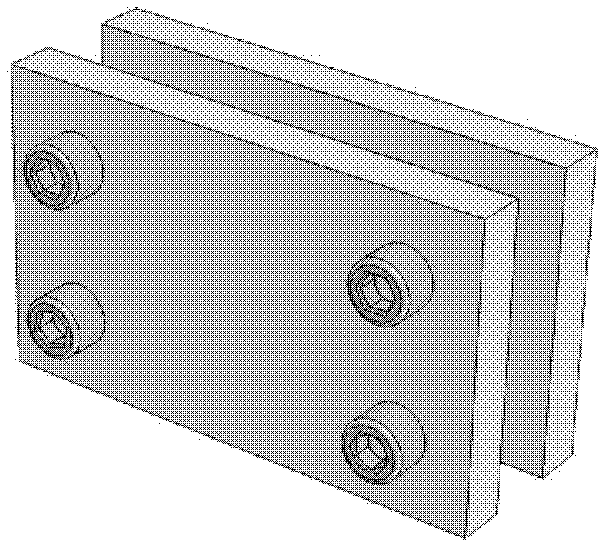

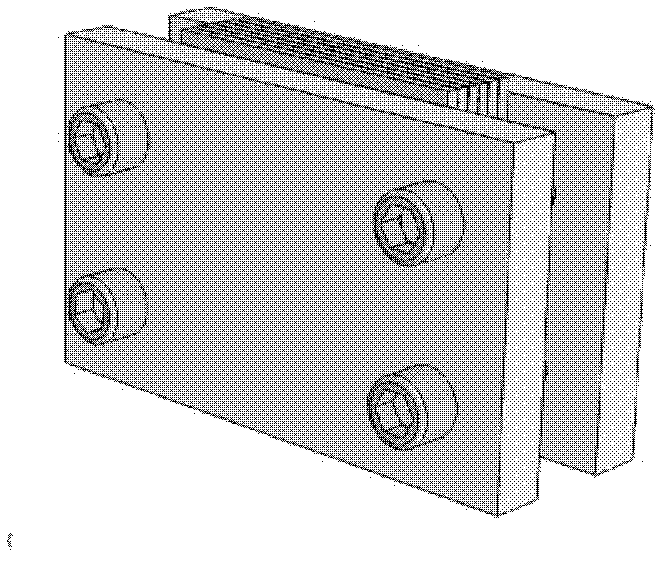

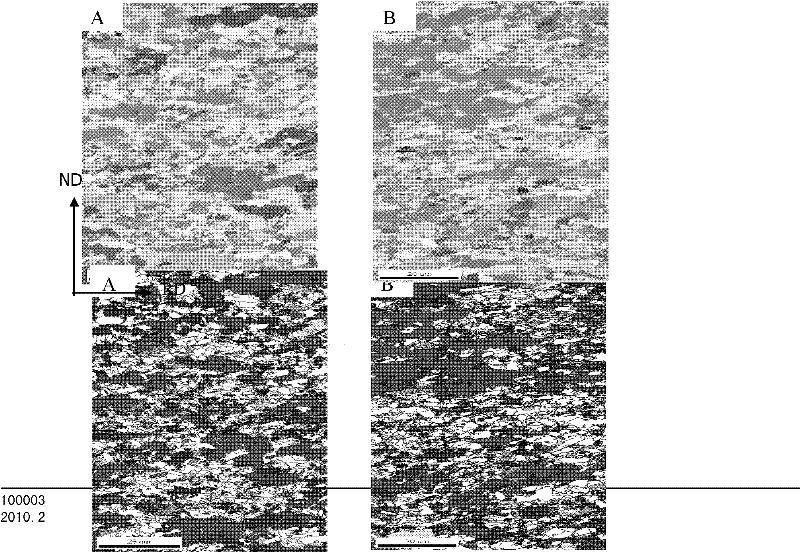

[0019] Cut the cold-rolled Ni5at.%W alloy base strip with a total deformation of >99% and an average thickness of 80um into initial samples of 5mm*10mm (ND*RD) along the RD direction, and neatly cut the samples according to the RD direction In order to ensure the stability of the samples during the grinding and polishing process and the rational use of sandpaper during one grinding and polishing process, 8 samples were selected as a group and stacked neatly. Fixtures first (see figure 1 ) to clean and ensure that the inside of the fixture is clean and smooth, then put the neatly stacked samples into the fixture, apply force alternately and evenly on both sides, so as to ensure that the base belt will not tilt during the fixing process, and the height left outside the fixture should be be consistent, such as figure 2 shown. Mechanically polish the sample fixed on the fixture, and the sample passes through 200 # , 400 # , 600 # , 800 # , 1500 # After polishing with high-...

Embodiment example 2

[0021] Cut the cold-rolled Ni5at.%W alloy base strip with a total deformation of >99% and an average thickness of 72um into initial samples of 5mm*10mm (ND*RD) along the RD direction, and neatly cut the samples according to the RD direction In order to ensure the stability of the samples during the grinding and polishing process and the rational use of sandpaper during one grinding and polishing process, 8 samples were selected as a group and stacked neatly. Clean the jig first, and ensure that the inner side of the jig is clean and flat, then put the neatly stacked samples into the jig, and apply force alternately and evenly on both sides to ensure that the base belt will not tilt during the fixing process, and the parts left outside the jig The height should be consistent, such as figure 2 shown. Mechanically polish the sample fixed on the fixture, and the sample passes through 200 # , 400 # , 600 # , 800 # , 1500 # After polishing with high-quality water abrasive pap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com