Polyimide paint for optical fiber and preparation method thereof

A polyimide and optical fiber technology, applied in the direction of coating, etc., can solve the problems of low temperature resistance level, application limitation, poor resistance to alternating cycles of cold and heat, etc., and achieves fewer types of use, convenient sources and good The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

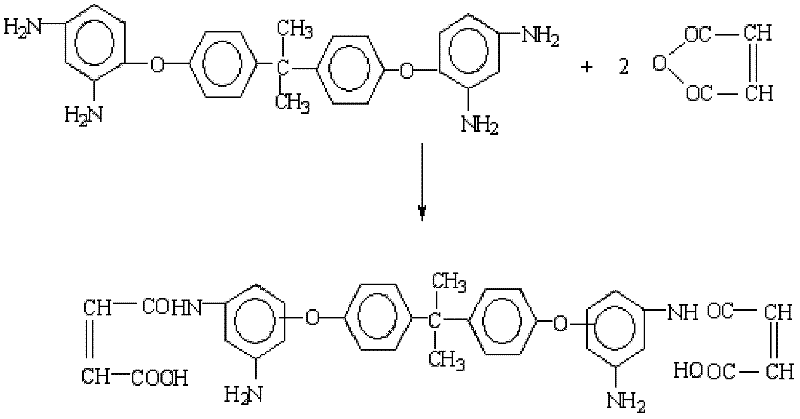

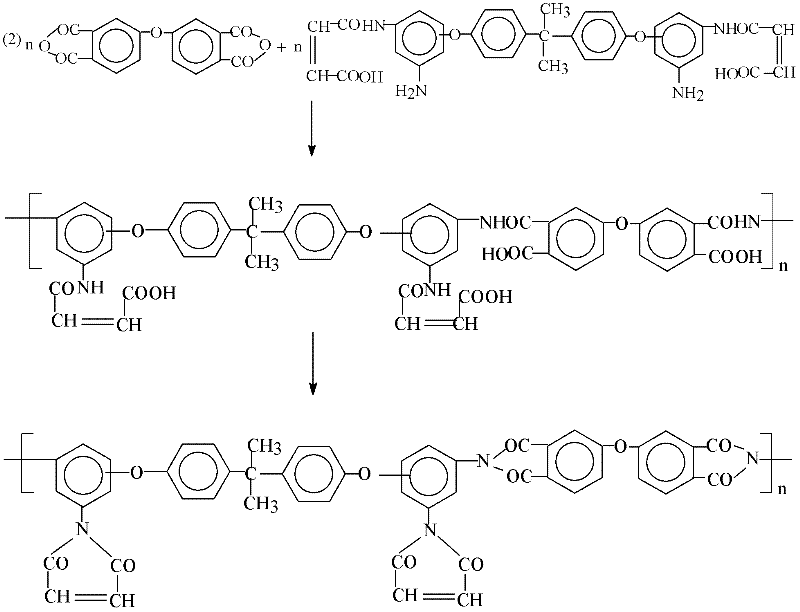

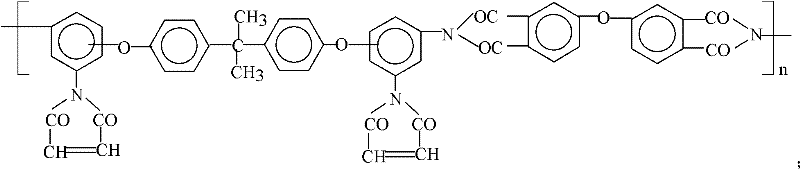

Method used

Image

Examples

Embodiment 1

[0037] Put 440.5 grams (1.0 moles) of 2,2-bis[4-(2,4-diaminophenoxy)phenyl]propane and 5500 milliliters of N-methyl-2-pyrrolidone into a highly polar aprotic organic solvent In the reaction kettle, at room temperature, after stirring and dissolving completely, add 196.0 grams (2.0 moles) of maleic anhydride solid powder, stir at room temperature until completely dissolved, continue stirring for 0.5 to 1 hour, then add 310.0 grams (1.0 moles) of 3, 3',4,4'-Tetracarboxydiphenyl ether dianhydride, stirred and reacted at 0°C-5°C for 2 to 3 hours to obtain a homogeneous transparent viscous resin solution; add 3000 ml of toluene azeotropic dehydrating agent, total After boiling and reflux, separating water and stirring for 6-8 hours, separate about 3500 ml of solvent, cool to room temperature, and obtain 5910 g of maleimide-based polyimide solution (referred to as component A), and measure the solid content was 15.4%.

Embodiment 2

[0039] 36.6 grams (0.1 moles) of 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane, 20.0 grams (0.1 moles) of 4,4'-diaminodiphenyl ether, 10.0 grams of α, ω- Diaminopropyl polydimethylsiloxane (the molar number of amino groups is 0.004, product of Shanghai Ruitu Electronic Materials Co., Ltd., brand YSI004) and 600 ml of N-methylpyrrolidone solvent are mixed at room temperature, and after stirring and dissolving completely, add 58.8 grams (0.2 moles) of 3,3',4,4'-tetracarboxybiphenyl dianhydride and 1.1 grams (0.002 moles) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl ] Aromatic dibasic acid anhydride of propane dianhydride, after reacting at room temperature for 4 to 5 hours, a homogeneous transparent viscous resin solution is obtained; add 1200 ml of toluene, react with azeotropic water separation for 6 to 8 hours, and separate the solvent About 1100 ml was cooled to room temperature to obtain 807 g of phenolic hydroxyl-containing polysiloxane imide solution (referred to as com...

Embodiment 3

[0041] 29.0 grams (0.1 moles) of 4,4'-diamino-4"-hydroxytriphenylmethane, 41.0 grams (0.1 moles) of 2,2-bis[4-(4-aminophenoxy)phenyl]propane, 20.0 grams (0.1 moles) of 3,4'-diaminodiphenyl ether, 10.0 grams of α, ω-diaminopropyl polydimethylsiloxane (the molar number of amino groups is 0.004, products of Shanghai Ruitu Electronic Materials Co., Ltd. , brand YSI004) and 1200 ml of N-methylpyrrolidone solvent were mixed at room temperature, and after stirring and dissolving completely, 21.8 g (0.1 mol) of pyromellitic dianhydride, 58.8 g (0.2 mol) of 3,3',4,4 '-Tetracarboxybiphenyl dianhydride and 1.1 grams (0.002 moles) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride, react at room temperature After 4-5 hours, a homogeneous transparent viscous resin solution was obtained; 800 ml of toluene was added, and after 6-8 hours of azeotropic water separation reaction, about 1000 ml of solvent was separated and cooled to room temperature to obtain 1107 g of phenolic hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com