Functional material for purifying air and regulating humidity and its preparation method

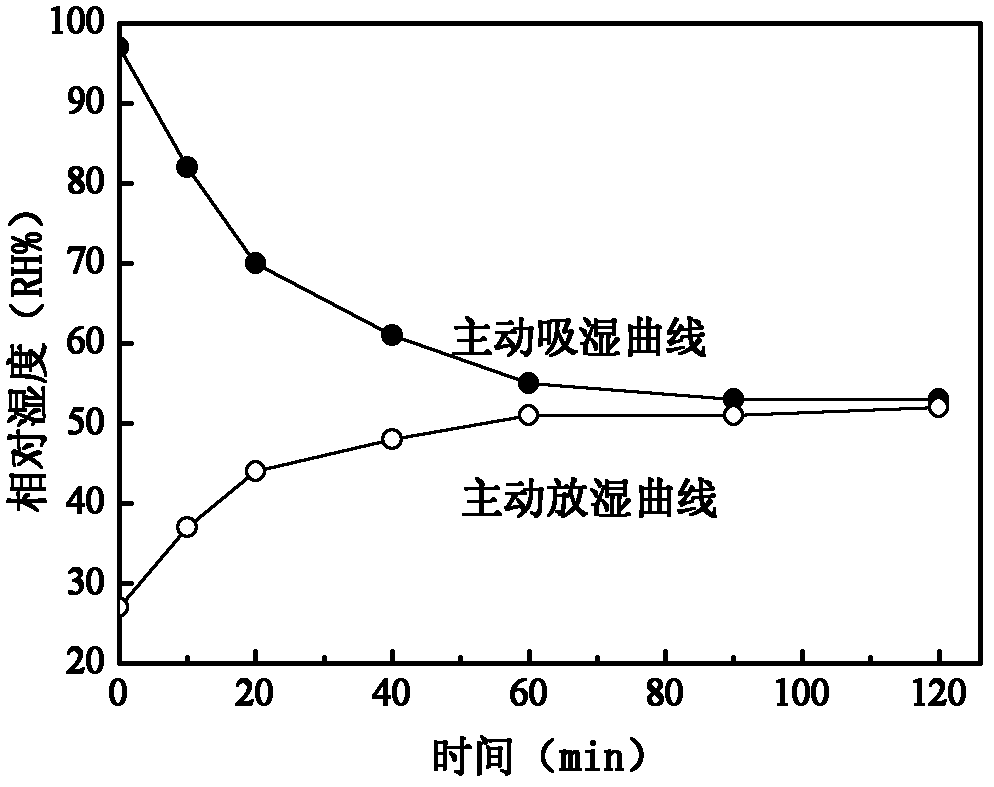

A technology of air purification and functional materials, applied in disinfection, deodorization, etc., can solve the problems of small humidity control and slow response speed, and achieve the effect of strong humidity control ability and high humidity capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) The purchased diatomite raw material is roasted at 600° C. for 60 minutes; after that, it is put into 70% H by mass percentage in the ratio of solid-liquid mass ratio 1:3. 2 SO 4 Soak in aqueous solution for 3 hours at 100°C. Next, the above-mentioned diatomite was added to a 4% aqueous solution of cetyltrimethylammonium bromide (CTAB) in a ratio of 1:4 by solid-to-liquid ratio, and stirred at 60° C. for 2 h; cooled , washing, vacuum drying at 80°C for 60 minutes, grinding and crushing to obtain organically modified diatomite.

[0023] (2) the preparation mass fraction is the NaOH aqueous solution of 25%, under the condition of ice-water bath, the metered NaOH solution is slowly dropped into the acrylic acid to obtain the acrylic acid-sodium acrylate monomer solution with a neutralization degree of 70%; then the acrylic acid-sodium acrylate Organically modified diatomite with 60% mass of the monomer solution was added into the monomer solution for stirring and mix...

Embodiment 2

[0027] (1) Roasting the purchased diatomite raw material at 700°C for 30min; then put it into a 60% H 2 SO 4 Soak in aqueous solution for 4 hours at 80°C. Next, the above-mentioned diatomite was added to a 10% by mass percent cetyltrimethylammonium bromide (CTAB) aqueous solution at a solid-to-liquid ratio of 1:5, and stirred at 40° C. for 3 h; cooled , washing, vacuum drying at 100°C for 90 minutes, grinding and crushing to obtain organically modified diatomite.

[0028] (2) The KOH aqueous solution with a mass fraction of 25% is prepared, and the metered NaOH solution is slowly dripped into acrylic acid under ice-water bath conditions to obtain an acrylic acid-sodium acrylate monomer solution with a neutralization degree of 50%; then the acrylic acid-sodium acrylate Organically modified diatomite with 70% mass of the monomer solution was added to the monomer solution for stirring and mixing, and ultrasonic vibration was performed for 40 minutes to disperse the solution to ...

Embodiment 3

[0032] (1) Roasting the purchased diatomite raw material at 550°C for 120min; then put it into a mass percentage of 90% H 2 SO 4 Soak in aqueous solution for 2 hours at 100°C. Next, the above-mentioned diatomite was added to a 1% by mass percent cetyltrimethylammonium bromide (CTAB) aqueous solution at a solid-to-liquid ratio of 1:2, and stirred at 80° C. for 4 h; cooled , washing, vacuum drying at 100°C for 80 minutes, grinding and crushing to obtain organically modified diatomite.

[0033] (2) The KOH aqueous solution with a mass fraction of 25% is prepared, and the metered NaOH solution is slowly dripped into acrylic acid under ice-water bath conditions to obtain an 80% neutralization degree of acrylic acid-sodium acrylate monomer solution; then the acrylic acid-sodium acrylate 10% organically modified diatomite by mass of the monomer solution was added into the monomer solution for stirring and mixing, and ultrasonic vibration was performed for 40 minutes to disperse the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com